3/4 to 3/4 PVC Fittings and Adapters Explained

Understanding 3/4 to 3/4 PVC Fittings and Adapters

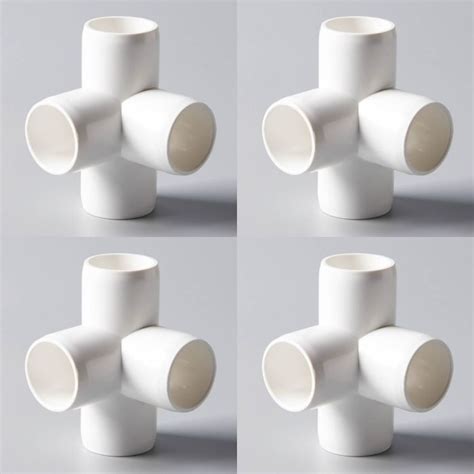

PVC fittings and adapters are essential components in various plumbing, irrigation, and industrial applications. Among the various types and sizes available, 3⁄4 to 3⁄4 PVC fittings and adapters are widely used for connecting pipes of the same diameter. In this article, we will delve into the world of 3⁄4 to 3⁄4 PVC fittings and adapters, exploring their types, applications, and benefits.

What are 3/4 to 3/4 PVC Fittings and Adapters?

3⁄4 to 3⁄4 PVC fittings and adapters are pipe connectors used to join two 3⁄4-inch PVC pipes together. These fittings are designed to provide a secure, leak-proof connection between pipes of the same diameter. They are commonly used in residential, commercial, and industrial plumbing systems, as well as in irrigation and water treatment applications.

Types of 3/4 to 3/4 PVC Fittings and Adapters

There are several types of 3⁄4 to 3⁄4 PVC fittings and adapters available, each serving a specific purpose:

- Couplings: Used to connect two 3⁄4-inch PVC pipes together, forming a straight line.

- Elbows: Used to change the direction of a 3⁄4-inch PVC pipe by 90 degrees.

- Tees: Used to connect three 3⁄4-inch PVC pipes together, forming a T-shaped joint.

- Reducers: Used to connect a 3⁄4-inch PVC pipe to a smaller or larger pipe size.

- Adapters: Used to connect a 3⁄4-inch PVC pipe to a pipe of a different material, such as copper or ABS.

Applications of 3/4 to 3/4 PVC Fittings and Adapters

3⁄4 to 3⁄4 PVC fittings and adapters are used in a wide range of applications, including:

- Plumbing systems: Connecting pipes under sinks, toilets, and around water heaters.

- Irrigation systems: Connecting pipes to sprinklers, drippers, and other irrigation devices.

- Water treatment systems: Connecting pipes to filters, pumps, and other water treatment equipment.

- Industrial processes: Connecting pipes to machinery, equipment, and other industrial processes.

Benefits of 3/4 to 3/4 PVC Fittings and Adapters

3⁄4 to 3⁄4 PVC fittings and adapters offer several benefits, including:

- Easy installation: Simple to install, requiring minimal tools and expertise.

- Leak-proof connections: Provide a secure, leak-proof connection between pipes.

- Chemical resistance: Resistant to many chemicals, making them ideal for industrial applications.

- Cost-effective: Less expensive than other types of pipe connectors, such as metal or copper.

How to Choose the Right 3/4 to 3/4 PVC Fitting or Adapter

When selecting a 3⁄4 to 3⁄4 PVC fitting or adapter, consider the following factors:

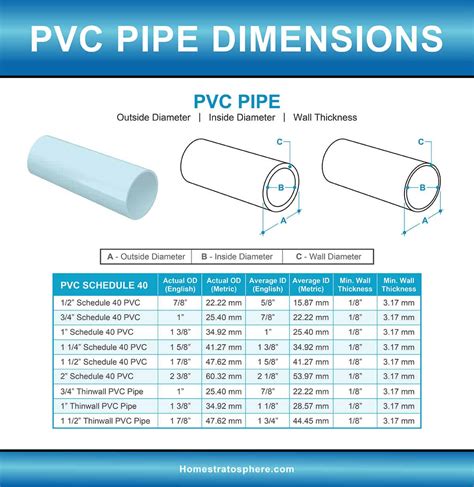

- Pipe size: Ensure the fitting or adapter matches the pipe size.

- Material: Consider the type of PVC material, such as Schedule 40 or Schedule 80.

- Application: Choose a fitting or adapter suitable for the intended application.

- Pressure rating: Select a fitting or adapter that meets the required pressure rating.

💡 Note: Always follow the manufacturer's instructions and recommendations when selecting and installing 3/4 to 3/4 PVC fittings and adapters.

Conclusion

In conclusion, 3⁄4 to 3⁄4 PVC fittings and adapters are essential components in various plumbing, irrigation, and industrial applications. By understanding the types, applications, and benefits of these fittings and adapters, you can make informed decisions when selecting the right connector for your specific needs.

What is the difference between a 3⁄4 to 3⁄4 PVC coupling and an elbow?

+

A 3⁄4 to 3⁄4 PVC coupling is used to connect two 3⁄4-inch PVC pipes together, forming a straight line, while an elbow is used to change the direction of a 3⁄4-inch PVC pipe by 90 degrees.

Can I use a 3⁄4 to 3⁄4 PVC adapter to connect a PVC pipe to a copper pipe?

+

Yes, a 3⁄4 to 3⁄4 PVC adapter can be used to connect a PVC pipe to a copper pipe, but ensure the adapter is specifically designed for this purpose and follows the manufacturer’s instructions.

What is the pressure rating of a 3⁄4 to 3⁄4 PVC fitting?

+

The pressure rating of a 3⁄4 to 3⁄4 PVC fitting depends on the type of fitting and the manufacturer. Always check the manufacturer’s specifications and recommendations for the specific fitting being used.