5 Ways to Work Harden 304 Stainless Steel

Introduction to Hardening 304 Stainless Steel

304 stainless steel is a popular material for various applications due to its excellent corrosion resistance, formability, and weldability. However, it is not as hard as other materials, which can be a disadvantage in certain situations. Fortunately, there are ways to harden 304 stainless steel to improve its mechanical properties. In this article, we will discuss five methods to harden 304 stainless steel.

1. Cold Working

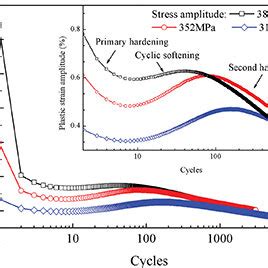

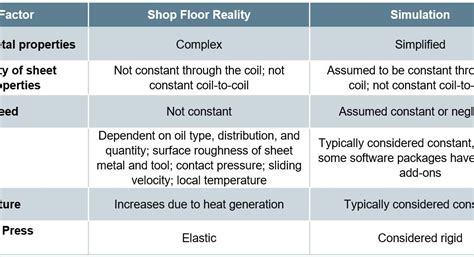

Cold working is a process that involves deforming the metal at room temperature to create strain hardening. This method can increase the yield strength and hardness of 304 stainless steel. Cold working can be done through various techniques, such as:

- Rolling: Rolling is a process that involves passing the metal through a series of rollers to reduce its thickness and increase its hardness.

- Drawing: Drawing is a process that involves pulling the metal through a die to reduce its diameter and increase its hardness.

- Bending: Bending is a process that involves bending the metal to a specific shape to increase its hardness.

Cold working can increase the hardness of 304 stainless steel by up to 50%. However, it can also lead to a loss of ductility and corrosion resistance.

🔧 Note: Cold working can be done to a certain extent, beyond which the metal may become too hard and brittle.

2. Heat Treatment

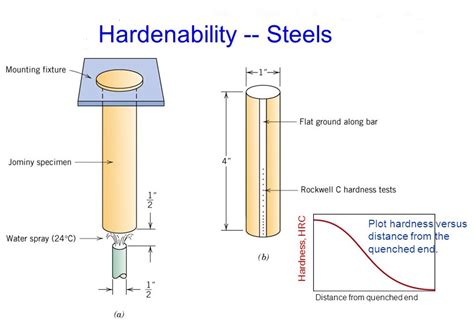

Heat treatment is a process that involves heating the metal to a specific temperature to alter its microstructure and properties. There are several heat treatment methods that can be used to harden 304 stainless steel, including:

- Austenitizing: Austenitizing involves heating the metal to a temperature of around 1900°F (1040°C) to form austenite, which is a hard and brittle phase.

- Quenching: Quenching involves rapidly cooling the metal after austenitizing to form martensite, which is a hard and strong phase.

- Tempering: Tempering involves heating the metal to a temperature of around 400°F (200°C) to reduce its hardness and increase its toughness.

Heat treatment can increase the hardness of 304 stainless steel by up to 30%. However, it can also lead to a loss of corrosion resistance and ductility.

🔧 Note: Heat treatment can be done in a controlled atmosphere to minimize the loss of corrosion resistance.

3. Nitriding

Nitriding is a process that involves heating the metal in a nitrogen-rich atmosphere to form nitrides, which are hard and wear-resistant compounds. Nitriding can increase the hardness of 304 stainless steel by up to 20%.

- Gas nitriding: Gas nitriding involves heating the metal in a nitrogen-rich atmosphere, such as ammonia or nitrogen gas.

- Salt bath nitriding: Salt bath nitriding involves heating the metal in a molten salt bath containing nitrogen.

Nitriding can improve the wear resistance and fatigue strength of 304 stainless steel. However, it can also lead to a loss of corrosion resistance.

🔧 Note: Nitriding can be done at relatively low temperatures, which can minimize the loss of corrosion resistance.

4. Carburizing

Carburizing is a process that involves heating the metal in a carbon-rich atmosphere to form carbides, which are hard and wear-resistant compounds. Carburizing can increase the hardness of 304 stainless steel by up to 30%.

- Gas carburizing: Gas carburizing involves heating the metal in a carbon-rich atmosphere, such as natural gas or propane.

- Pack carburizing: Pack carburizing involves heating the metal in a carbon-rich powder, such as charcoal or graphite.

Carburizing can improve the wear resistance and fatigue strength of 304 stainless steel. However, it can also lead to a loss of corrosion resistance.

🔧 Note: Carburizing can be done at relatively high temperatures, which can lead to a loss of corrosion resistance.

5. Boriding

Boriding is a process that involves heating the metal in a boron-rich atmosphere to form borides, which are hard and wear-resistant compounds. Boriding can increase the hardness of 304 stainless steel by up to 20%.

- Gas boriding: Gas boriding involves heating the metal in a boron-rich atmosphere, such as boron trichloride or boron trifluoride.

- Salt bath boriding: Salt bath boriding involves heating the metal in a molten salt bath containing boron.

Boriding can improve the wear resistance and fatigue strength of 304 stainless steel. However, it can also lead to a loss of corrosion resistance.

🔧 Note: Boriding can be done at relatively low temperatures, which can minimize the loss of corrosion resistance.

In conclusion, there are several methods to harden 304 stainless steel, each with its own advantages and disadvantages. The choice of method depends on the specific application and the desired properties of the material.

What is the best method to harden 304 stainless steel?

+

The best method to harden 304 stainless steel depends on the specific application and the desired properties of the material. Cold working, heat treatment, nitriding, carburizing, and boriding are all effective methods to harden 304 stainless steel.

Can 304 stainless steel be hardened to the same level as 440C stainless steel?

+

No, 304 stainless steel cannot be hardened to the same level as 440C stainless steel. 440C stainless steel has a higher carbon content and can be hardened to a higher level than 304 stainless steel.

What are the advantages and disadvantages of hardening 304 stainless steel?

+

The advantages of hardening 304 stainless steel include improved wear resistance, fatigue strength, and hardness. The disadvantages include a loss of corrosion resistance, ductility, and increased brittleness.