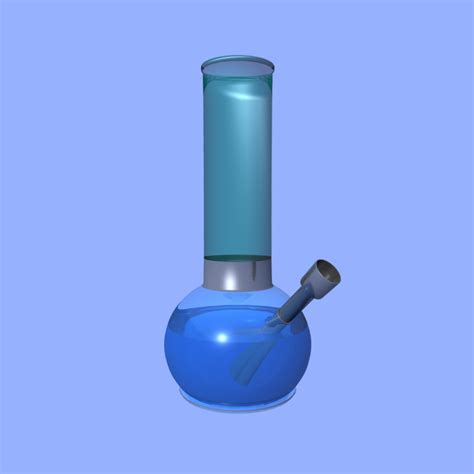

5 Ways to 3D Print a Mini Bong

Design Considerations for 3D Printing a Mini Bong

3D printing a mini bong requires careful consideration of several factors, including the design, material, and printing settings. In this article, we will explore five different methods for 3D printing a mini bong, highlighting the pros and cons of each approach.

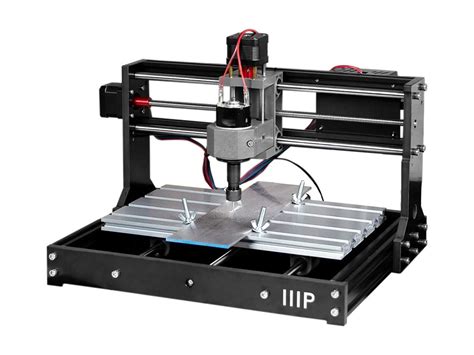

Method 1: Fused Deposition Modeling (FDM)

FDM is one of the most common 3D printing technologies, and it’s well-suited for printing mini bongs. To print a mini bong using FDM, you’ll need:

- A 3D printer with a heated bed and a nozzle diameter of at least 0.4mm

- A spool of PLA or ABS filament

- A 3D model of the mini bong, designed with a hollow interior and a small hole for the mouthpiece

Pros:

- FDM is a relatively fast and affordable 3D printing technology

- PLA and ABS filaments are widely available and easy to work with

- The resulting print can be sanded and painted for a smooth finish

Cons:

- FDM prints can be prone to warping and layer shifting, especially if the print bed is not properly calibrated

- The hollow interior of the mini bong may require additional support material, which can be difficult to remove

🚨 Note: When printing with FDM, make sure to use a low retraction setting to avoid creating a clogged nozzle.

Method 2: Stereolithography (SLA)

SLA is a resin-based 3D printing technology that produces highly detailed and accurate prints. To print a mini bong using SLA, you’ll need:

- An SLA 3D printer with a UV-curable resin

- A 3D model of the mini bong, designed with a hollow interior and a small hole for the mouthpiece

- A well-ventilated workspace and protective gear (gloves, goggles, etc.)

Pros:

- SLA prints are incredibly detailed and accurate, with a smooth finish

- The resulting print can be cured to create a waterproof seal

- SLA resins come in a wide range of colors and properties

Cons:

- SLA printing can be slow and expensive, especially for large prints

- The resin can be messy and hazardous to work with

- The print may require additional post-processing, such as sanding and painting

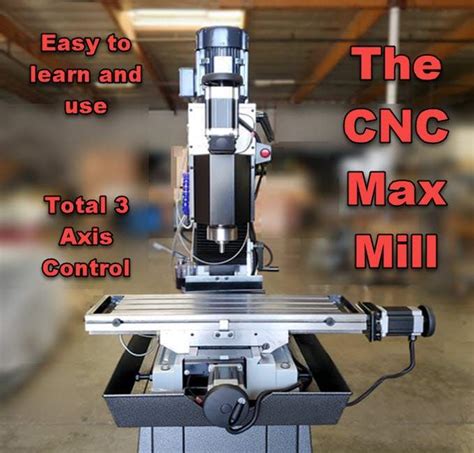

Method 3: Selective Laser Sintering (SLS)

SLS is a powder-based 3D printing technology that produces highly durable and functional prints. To print a mini bong using SLS, you’ll need:

- An SLS 3D printer with a powder bed and a laser

- A 3D model of the mini bong, designed with a hollow interior and a small hole for the mouthpiece

- A well-ventilated workspace and protective gear (gloves, goggles, etc.)

Pros:

- SLS prints are incredibly durable and functional, with a smooth finish

- The resulting print can be used as-is, without additional post-processing

- SLS powders come in a wide range of materials and properties

Cons:

- SLS printing can be expensive and limited to industrial-grade printers

- The powder can be messy and hazardous to work with

- The print may require additional support material, which can be difficult to remove

Method 4: Binder Jetting

Binder jetting is a powder-based 3D printing technology that produces highly detailed and accurate prints. To print a mini bong using binder jetting, you’ll need:

- A binder jetting 3D printer with a powder bed and a printhead

- A 3D model of the mini bong, designed with a hollow interior and a small hole for the mouthpiece

- A well-ventilated workspace and protective gear (gloves, goggles, etc.)

Pros:

- Binder jetting prints are incredibly detailed and accurate, with a smooth finish

- The resulting print can be used as-is, without additional post-processing

- Binder jetting powders come in a wide range of materials and properties

Cons:

- Binder jetting printing can be slow and expensive, especially for large prints

- The powder can be messy and hazardous to work with

- The print may require additional support material, which can be difficult to remove

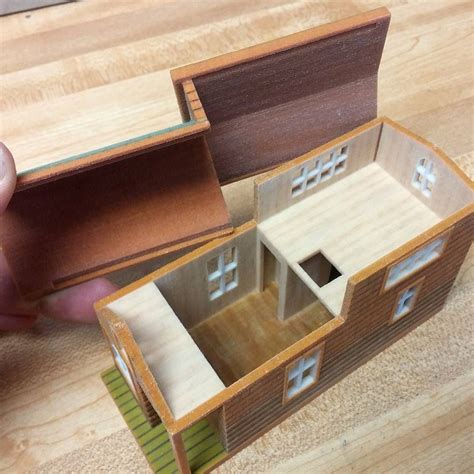

Method 5: Ceramic 3D Printing

Ceramic 3D printing is a specialized technology that produces highly detailed and functional ceramic prints. To print a mini bong using ceramic 3D printing, you’ll need:

- A ceramic 3D printer with a powder bed and a printhead

- A 3D model of the mini bong, designed with a hollow interior and a small hole for the mouthpiece

- A well-ventilated workspace and protective gear (gloves, goggles, etc.)

Pros:

- Ceramic 3D prints are incredibly durable and functional, with a smooth finish

- The resulting print can be used as-is, without additional post-processing

- Ceramic 3D printing powders come in a wide range of materials and properties

Cons:

- Ceramic 3D printing can be expensive and limited to specialized printers

- The powder can be messy and hazardous to work with

- The print may require additional support material, which can be difficult to remove

As we can see, each method has its pros and cons. When choosing a method, consider the desired finish, durability, and functionality of the mini bong. Additionally, make sure to follow proper safety protocols and use protective gear when working with 3D printing technologies.

The journey to creating a functional mini bong is not just about the 3D printing process, but also about the design, material selection, and post-processing techniques. By understanding the different methods and their limitations, you can create a high-quality mini bong that meets your needs and expectations.

The art of 3D printing a mini bong is a challenging but rewarding experience. With the right combination of design, material, and printing settings, you can create a functional and durable mini bong that provides a smooth and enjoyable smoking experience.

What is the best 3D printing method for a mini bong?

+

The best 3D printing method for a mini bong depends on the desired finish, durability, and functionality. FDM and SLA are popular choices for mini bongs, but SLS, binder jetting, and ceramic 3D printing can also produce high-quality results.

What is the most important factor to consider when designing a mini bong?

+

The most important factor to consider when designing a mini bong is the airflow and smoke flow. A well-designed mini bong should have a smooth and efficient airflow, with minimal resistance and turbulence.

Can I use a 3D printed mini bong for smoking?

+

Yes, a 3D printed mini bong can be used for smoking, but it’s essential to ensure that the print is functional and safe. Make sure to use a food-grade material and follow proper post-processing techniques to create a smooth and non-toxic finish.