Unlocking the Future: 3D Print Boeing Plane Models

Revolutionizing Aerospace Modeling with 3D Printing

The aviation industry has witnessed tremendous growth and innovation in recent years, with 3D printing emerging as a game-changer in the field of aerospace modeling. One of the most exciting applications of this technology is the creation of scale models of Boeing planes. In this blog post, we will delve into the world of 3D printing and explore its potential in producing accurate and detailed models of Boeing aircraft.

Understanding 3D Printing Technology

3D printing, also known as additive manufacturing, is a process of creating a physical object from a digital design by layering materials such as plastics, metals, and ceramics. This technology has been widely adopted in various industries, including aerospace, automotive, and healthcare. In the context of aerospace modeling, 3D printing offers several advantages over traditional methods, including increased accuracy, reduced production time, and lower costs.

Benefits of 3D Printing in Aerospace Modeling

The use of 3D printing in aerospace modeling offers several benefits, including:

- Increased accuracy: 3D printing allows for the creation of highly detailed and accurate models, which is essential in the aerospace industry where precision is paramount.

- Reduced production time: 3D printing enables rapid prototyping and production, reducing the time it takes to create a model from weeks to days.

- Lower costs: 3D printing eliminates the need for expensive tooling and molds, reducing the overall cost of production.

- Customization: 3D printing allows for the creation of customized models with specific features and details, making it ideal for bespoke aerospace modeling projects.

Creating 3D Printed Boeing Plane Models

Creating a 3D printed Boeing plane model requires several steps, including:

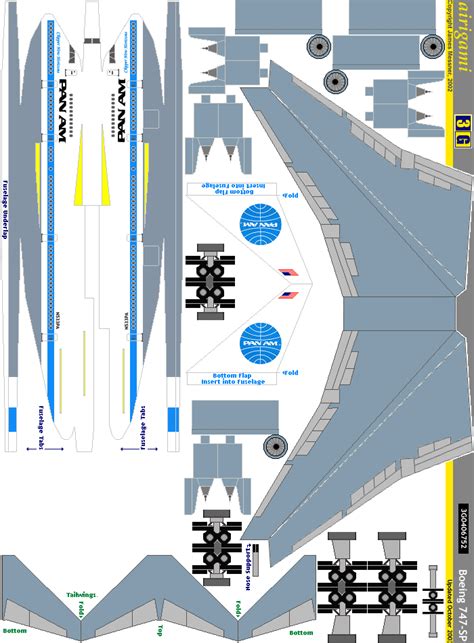

- Design: The first step is to create a digital design of the Boeing plane model using computer-aided design (CAD) software or other 3D modeling tools.

- Material selection: The next step is to select the material to be used for 3D printing, such as plastics, metals, or ceramics.

- 3D printing: The digital design is then sent to a 3D printer, which creates the model layer by layer.

- Post-processing: The final step is to apply post-processing techniques, such as painting or coating, to enhance the appearance of the model.

Notable Boeing Plane Models Created with 3D Printing

Several notable Boeing plane models have been created using 3D printing, including:

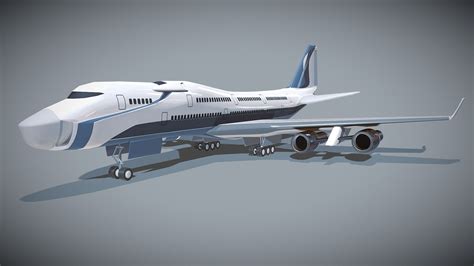

- Boeing 787 Dreamliner: A 1:100 scale model of the Boeing 787 Dreamliner was created using 3D printing, featuring intricate details and textures.

- Boeing 747-8: A 1:50 scale model of the Boeing 747-8 was created using 3D printing, showcasing the aircraft’s distinctive hump and wing design.

Challenges and Limitations of 3D Printing in Aerospace Modeling

While 3D printing offers several advantages in aerospace modeling, there are also some challenges and limitations to consider, including:

- Material limitations: The selection of materials for 3D printing is limited, and some materials may not be suitable for aerospace modeling.

- Scalability: 3D printing can be challenging when creating large models, and the process may be slower and more expensive.

- Accuracy: Ensuring accuracy and precision in 3D printing can be challenging, particularly when creating complex models.

📝 Note: The use of 3D printing in aerospace modeling is still a relatively new and evolving field, and ongoing research and development are needed to address the challenges and limitations associated with this technology.

Future Applications of 3D Printing in Aerospace Modeling

The future of 3D printing in aerospace modeling looks promising, with potential applications including:

- Full-scale aircraft production: 3D printing could be used to create full-scale aircraft parts and components, reducing production time and costs.

- Customized aircraft design: 3D printing could enable the creation of customized aircraft designs, allowing for greater flexibility and innovation in aerospace engineering.

- Aerospace education and training: 3D printing could be used to create educational models and training aids, enhancing the learning experience for aerospace students and professionals.

Embedding Images

Comparison of 3D Printing Technologies

| Technology | Advantages | Disadvantages |

|---|---|---|

| FDM (Fused Deposition Modeling) | Low cost, easy to use, and fast | Limited material options, poor surface finish |

| SLS (Selective Laser Sintering) | High accuracy, strong parts, and good surface finish | High cost, limited material options, and slow |

| SLA (Stereolithography) | High accuracy, good surface finish, and fast | High cost, limited material options, and poor mechanical properties |

In conclusion, 3D printing has revolutionized the field of aerospace modeling, offering several advantages over traditional methods, including increased accuracy, reduced production time, and lower costs. While there are still challenges and limitations to consider, the future of 3D printing in aerospace modeling looks promising, with potential applications including full-scale aircraft production, customized aircraft design, and aerospace education and training.

What is 3D printing?

+

3D printing, also known as additive manufacturing, is a process of creating a physical object from a digital design by layering materials such as plastics, metals, and ceramics.

What are the benefits of 3D printing in aerospace modeling?

+

The benefits of 3D printing in aerospace modeling include increased accuracy, reduced production time, and lower costs.

What are the challenges and limitations of 3D printing in aerospace modeling?

+

The challenges and limitations of 3D printing in aerospace modeling include material limitations, scalability, and accuracy.