3 Ways to Design a 3D Print Bust Hinge

Designing a 3D Print Bust Hinge: A Comprehensive Guide

Designing a 3D print bust hinge requires a combination of technical skills and creativity. A well-designed hinge can make a significant difference in the overall functionality and aesthetic appeal of a 3D printed bust. In this article, we will explore three different ways to design a 3D print bust hinge, including the pros and cons of each approach.

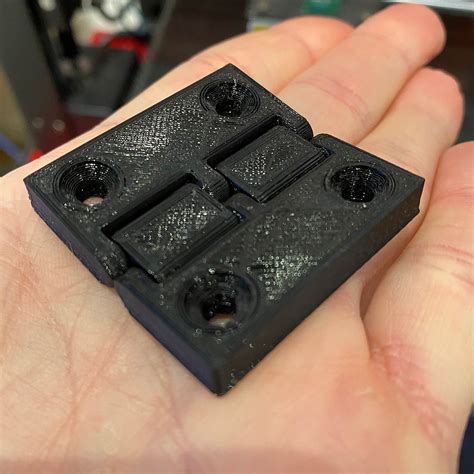

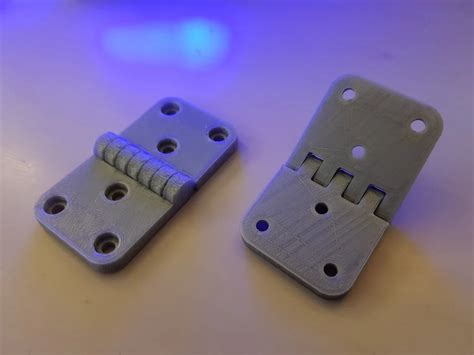

Method 1: Pin-and-Axle Hinge Design

The pin-and-axle hinge design is a classic approach to creating a hinge for a 3D printed bust. This design involves creating a small pin or axle that connects the two parts of the bust, allowing for smooth rotation.

🔧 Note: This design requires a high level of precision and accuracy to ensure proper alignment and smooth rotation.

To design a pin-and-axle hinge, follow these steps:

- Create a small pin or axle that connects the two parts of the bust.

- Design a small hole or recess in each part of the bust to accommodate the pin or axle.

- Use a 3D modeling software to create a precise alignment of the pin or axle with the holes or recesses.

- Use a strong adhesive or mechanical fastener to secure the pin or axle in place.

Pros:

- Smooth rotation and precise alignment

- Can be designed to be highly durable and long-lasting

- Can be used with a variety of materials, including plastics and metals

Cons:

- Requires high precision and accuracy to ensure proper alignment

- Can be difficult to design and assemble, especially for complex geometries

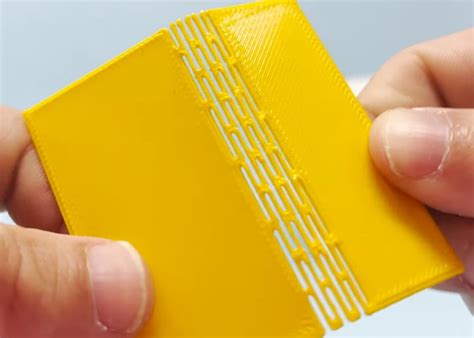

Method 2: Living Hinge Design

The living hinge design is a popular approach to creating a hinge for 3D printed objects. This design involves creating a thin, flexible section of material that connects the two parts of the bust, allowing for smooth rotation.

💡 Note: This design is ideal for objects that require a high degree of flexibility and movement.

To design a living hinge, follow these steps:

- Create a thin, flexible section of material that connects the two parts of the bust.

- Design the hinge to be curved or angled to allow for smooth rotation.

- Use a 3D modeling software to create a smooth, continuous surface for the hinge.

- Use a material with high flexibility and durability, such as a thermoplastic or elastomer.

Pros:

- Allows for smooth rotation and high flexibility

- Can be designed to be highly durable and long-lasting

- Can be used with a variety of materials, including plastics and elastomers

Cons:

- Can be prone to wear and tear, especially with repeated use

- Can be difficult to design and assemble, especially for complex geometries

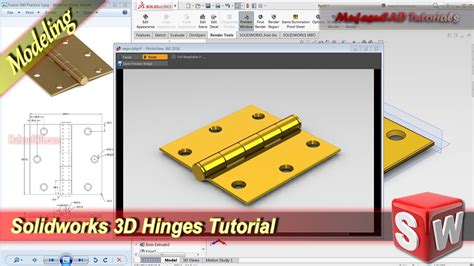

Method 3: Socket-and-Ball Hinge Design

The socket-and-ball hinge design is a popular approach to creating a hinge for 3D printed objects. This design involves creating a small socket or receptacle in one part of the bust, and a corresponding ball or pivot point in the other part.

🤔 Note: This design is ideal for objects that require a high degree of precision and control.

To design a socket-and-ball hinge, follow these steps:

- Create a small socket or receptacle in one part of the bust.

- Design a corresponding ball or pivot point in the other part of the bust.

- Use a 3D modeling software to create a precise alignment of the socket and ball.

- Use a strong adhesive or mechanical fastener to secure the ball in place.

Pros:

- Allows for precise control and smooth rotation

- Can be designed to be highly durable and long-lasting

- Can be used with a variety of materials, including plastics and metals

Cons:

- Can be prone to wear and tear, especially with repeated use

- Can be difficult to design and assemble, especially for complex geometries

| Hinge Design | Pros | Cons |

|---|---|---|

| Pin-and-Axle | Smooth rotation, precise alignment, durable | Requires high precision, difficult to design and assemble |

| Living Hinge | Smooth rotation, flexible, durable | Prone to wear and tear, difficult to design and assemble |

| Socket-and-Ball | Precise control, smooth rotation, durable | Prone to wear and tear, difficult to design and assemble |

In conclusion, designing a 3D print bust hinge requires a combination of technical skills and creativity. The three methods outlined in this article offer different approaches to creating a hinge, each with its own pros and cons. By considering the specific needs and requirements of the project, designers can choose the best approach to create a functional and aesthetically pleasing hinge.

What is the best hinge design for a 3D printed bust?

+

The best hinge design for a 3D printed bust depends on the specific needs and requirements of the project. The three methods outlined in this article offer different approaches to creating a hinge, each with its own pros and cons.

How do I ensure precise alignment of the hinge components?

+

To ensure precise alignment of the hinge components, use a 3D modeling software to create a precise alignment of the pin or axle with the holes or recesses. Additionally, use a strong adhesive or mechanical fastener to secure the pin or axle in place.

What materials are suitable for 3D printing a hinge?

+

A variety of materials can be used for 3D printing a hinge, including plastics, metals, and elastomers. The choice of material depends on the specific needs and requirements of the project, including durability, flexibility, and aesthetic appeal.