5 Ways to Perfectly 3D Print a Bust Open

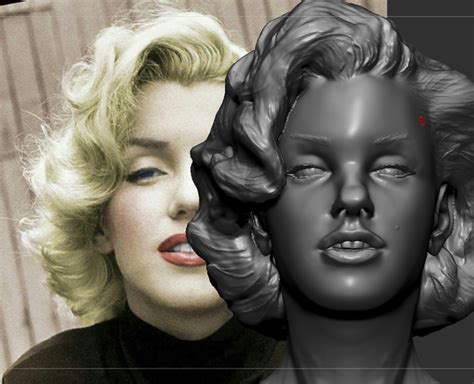

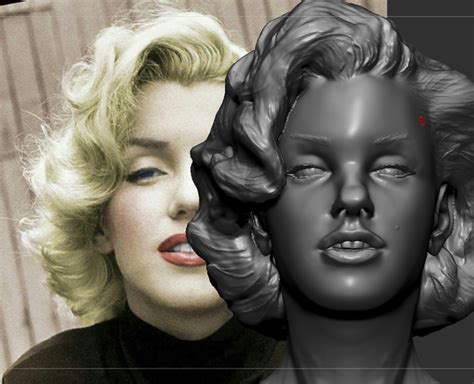

Understanding the Basics of 3D Printing a Bust

When it comes to 3D printing a bust, there are several factors to consider in order to achieve a perfectly printed model. A bust, being a detailed and intricate object, requires careful planning and execution to capture its features accurately. In this article, we will explore five ways to perfectly 3D print a bust, covering topics such as model preparation, printing settings, and post-processing techniques.

1. Model Preparation: Cleaning and Repairing the Model

Before sending your bust model to the 3D printer, it’s essential to ensure that it’s clean and free of errors. This step is crucial in achieving a successful print. Here are some tips to help you prepare your model:

- Remove unnecessary features: If your bust model has features that are not essential to its overall shape, consider removing them. This will help reduce the complexity of the model and prevent potential printing issues.

- Fix holes and gaps: Use a 3D modeling software to fix any holes or gaps in the model. This will prevent the printer from creating weak points in the print.

- Simplify the model: Simplify the model by reducing the number of polygons and merging overlapping faces. This will help reduce the file size and improve printing speed.

🔧 Note: Use a 3D modeling software like Blender or Tinkercad to clean and repair your model.

2. Printing Settings: Choosing the Right Resolution and Infill

The printing settings you choose can significantly impact the quality of your bust print. Here are some tips to help you choose the right resolution and infill:

- Choose a high resolution: A high resolution will allow you to capture the intricate details of the bust. A resolution of 0.1-0.2 mm is recommended.

- Select the right infill pattern: The infill pattern you choose will affect the strength and weight of the print. A grid or hexagonal pattern is recommended for bust prints.

- Adjust the infill density: The infill density will affect the weight and strength of the print. A density of 10-20% is recommended for bust prints.

| Printing Setting | Recommended Value |

|---|---|

| Resolution | 0.1-0.2 mm |

| Infill Pattern | Grid or Hexagonal |

| Infill Density | 10-20% |

3. Printing Orientation: Minimizing Support Material

The printing orientation you choose can significantly impact the amount of support material required. Here are some tips to help you minimize support material:

- Print with the face upwards: Printing the bust with the face upwards will minimize the amount of support material required.

- Use a 45-degree angle: Printing the bust at a 45-degree angle will help reduce the amount of support material required.

- Use a brim or raft: Adding a brim or raft to the print will help prevent warping and reduce the amount of support material required.

📐 Note: Use a slicing software like Cura or Slic3r to adjust the printing orientation and add a brim or raft.

4. Post-Processing: Sanding and Painting

Post-processing is an essential step in achieving a perfectly printed bust. Here are some tips to help you sand and paint your bust:

- Sanding: Use a fine-grit sandpaper to smooth out the surface of the bust. This will help remove any layer lines or imperfections.

- Painting: Use a primer and paint to add color and texture to the bust. You can also use a sealant to protect the paint and give it a glossy finish.

- Use a fine-grit sandpaper (120-220 grit) to smooth out the surface.

- Apply a primer to the bust before painting.

- Use acrylic or enamel paint to add color and texture.

- Apply a sealant to protect the paint and give it a glossy finish.

5. Tips and Tricks: Achieving a Perfect Bust Print

Here are some additional tips and tricks to help you achieve a perfectly printed bust:

- Use a 3D printing thermometer: A 3D printing thermometer will help you monitor the temperature of your printer and ensure that it’s within the optimal range.

- Use a print bed adhesion sheet: A print bed adhesion sheet will help prevent the bust from warping or detaching from the print bed.

- Print in a well-ventilated area: Printing in a well-ventilated area will help prevent the buildup of fumes and particles.

🔧 Note: Use a 3D printing thermometer and print bed adhesion sheet to ensure a successful print.

In conclusion, achieving a perfectly printed bust requires careful planning and execution. By following the tips and tricks outlined in this article, you can ensure that your bust print turns out perfectly.

What is the recommended resolution for printing a bust?

+

A resolution of 0.1-0.2 mm is recommended for printing a bust.

How do I minimize support material when printing a bust?

+

Printing the bust with the face upwards and using a 45-degree angle can help minimize support material.

What type of paint should I use to paint a bust?

+

Acrylic or enamel paint can be used to add color and texture to a bust.