Rev Up with 3D Printed Motorsport Innovations

Rev Up with 3D Printed Motorsport Innovations

The world of motorsports is a domain where precision, speed, and innovation converge. As technology advances, the sport is witnessing a significant transformation, thanks to the integration of 3D printing. This cutting-edge technique is revolutionizing the way teams design, test, and manufacture components, ultimately enhancing performance and efficiency. In this article, we will delve into the realm of 3D printed motorsport innovations and explore the vast potential they hold.

Advantages of 3D Printing in Motorsports

The incorporation of 3D printing in motorsports offers several benefits that are hard to ignore:

- Reduced weight: 3D printing enables the creation of complex geometries and lattice structures that can significantly reduce the weight of components without compromising their strength.

- Increased speed: By optimizing component design and minimizing weight, 3D printing can contribute to improved acceleration and overall speed.

- Enhanced customization: 3D printing allows for rapid prototyping and customization, enabling teams to create tailored components that meet specific performance requirements.

- Cost-effective: Traditional manufacturing methods often involve significant material waste and labor costs. 3D printing minimizes waste and can reduce production costs.

- Rapid production: 3D printing enables rapid production, which is crucial in the fast-paced world of motorsports where teams need to respond quickly to changing circumstances.

Applications of 3D Printing in Motorsports

The applications of 3D printing in motorsports are diverse and expanding rapidly:

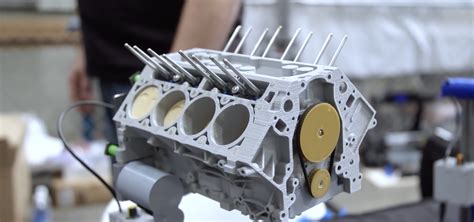

- Engine components: 3D printing is used to create complex engine components, such as cylinder heads, engine blocks, and gearboxes.

- Aerodynamic components: 3D printing enables the creation of intricate aerodynamic components, such as spoilers, diffusers, and winglets.

- Chassis and bodywork: 3D printing is used to create lightweight chassis and bodywork components, such as frames, panels, and spoilers.

- Safety equipment: 3D printing is used to create customized safety equipment, such as helmets, seats, and restraints.

Case Studies: Successful Implementations of 3D Printing in Motorsports

Several teams and organizations have successfully implemented 3D printing in their motorsport endeavors:

- Formula 1: The Renault F1 team used 3D printing to create a complex gearbox component that reduced weight by 20% and increased performance.

- IndyCar: The IndyCar Series has partnered with 3D printing companies to create customized components, such as engine blocks and aerodynamic parts.

- Motocross: The Red Bull KTM Factory Racing team used 3D printing to create a customized motorcycle frame that reduced weight by 15% and improved handling.

Challenges and Limitations of 3D Printing in Motorsports

While 3D printing offers numerous benefits, there are challenges and limitations to consider:

- Material properties: The mechanical properties of 3D printed materials can be inconsistent, affecting performance and reliability.

- Scalability: Large-scale 3D printing can be time-consuming and costly.

- Regulatory framework: The regulatory framework for 3D printed components in motorsports is still evolving and can be complex.

Future Directions: The Potential of 3D Printing in Motorsports

As technology advances, the potential of 3D printing in motorsports is vast and exciting:

- Increased use of advanced materials: The development of new materials with improved mechanical properties will expand the possibilities of 3D printing in motorsports.

- Integration with other technologies: The integration of 3D printing with other technologies, such as artificial intelligence and machine learning, will enable more efficient design and optimization.

- Expanded applications: 3D printing will be applied to a wider range of components, including electronics, sensors, and actuators.

🚀 Note: The use of 3D printing in motorsports is constantly evolving, and the development of new technologies and materials will continue to push the boundaries of what is possible.

Conclusion

The integration of 3D printing in motorsports has revolutionized the way teams design, test, and manufacture components. The benefits of reduced weight, increased speed, and enhanced customization have made 3D printing an essential tool in the pursuit of performance and efficiency. As technology advances, the potential of 3D printing in motorsports will continue to expand, enabling teams to push the boundaries of what is possible.

What are the main advantages of 3D printing in motorsports?

+

The main advantages of 3D printing in motorsports include reduced weight, increased speed, enhanced customization, cost-effectiveness, and rapid production.

What are some common applications of 3D printing in motorsports?

+

Common applications of 3D printing in motorsports include engine components, aerodynamic components, chassis and bodywork, and safety equipment.

What are some challenges and limitations of 3D printing in motorsports?

+

Challenges and limitations of 3D printing in motorsports include material properties, scalability, and regulatory framework.