5 Ways to 3D Print Threaded Panels Perfectly

Introduction to 3D Printing Threaded Panels

Three-dimensional (3D) printing has revolutionized the way we design and manufacture objects. One of the most challenging tasks in 3D printing is creating threaded panels with precision and accuracy. Threaded panels are essential in various applications, including mechanical engineering, robotics, and product design. In this article, we will discuss five ways to 3D print threaded panels perfectly.

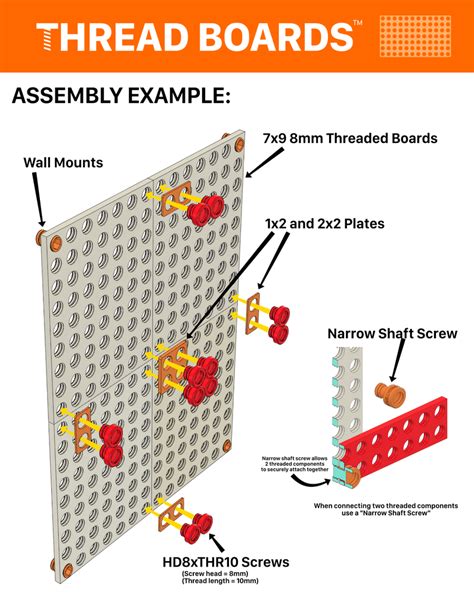

Understanding Threaded Panels

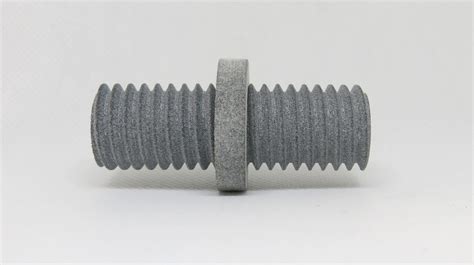

Threaded panels are components with internal threads that allow for easy assembly and disassembly. They are commonly used in mechanical systems, such as gears, pulleys, and bearings. The threads on these panels must be precise and accurate to ensure smooth operation and prevent damage to the surrounding components.

5 Ways to 3D Print Threaded Panels Perfectly

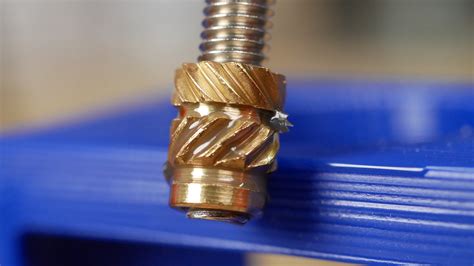

1. Using Threaded Inserts

Threaded inserts are a popular method for creating threaded panels. This method involves printing the panel with a hole and then inserting a threaded insert. The insert is typically made of metal or plastic and is designed to provide a secure and precise thread.

Advantages:

- Easy to implement

- High precision and accuracy

- Can be used with various materials

Disadvantages:

- Requires additional post-processing steps

- Can be expensive

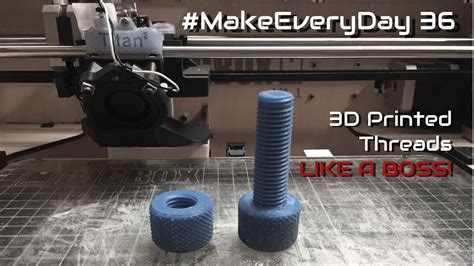

2. Printing with Threaded Filaments

Some 3D printing filaments, such as metal-filled or carbon fiber-filled filaments, can be used to print threaded panels directly. These filaments are designed to provide high strength and precision, making them ideal for creating threaded panels.

Advantages:

- No post-processing required

- High strength and precision

- Can be used with various printing technologies

Disadvantages:

- Limited availability of threaded filaments

- Can be expensive

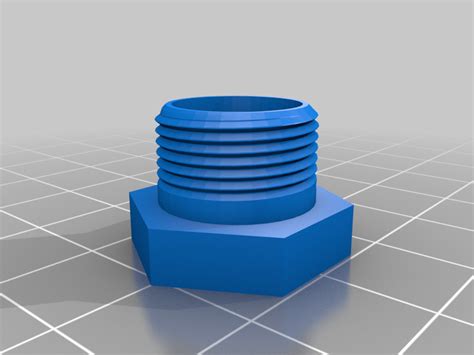

3. Using a Threaded Nozzle

A threaded nozzle is a specialized 3D printing nozzle designed specifically for printing threaded panels. This nozzle has a thread-shaped tip that allows for precise and accurate printing of threads.

Advantages:

- High precision and accuracy

- Easy to implement

- Can be used with various materials

Disadvantages:

- Limited availability of threaded nozzles

- Can be expensive

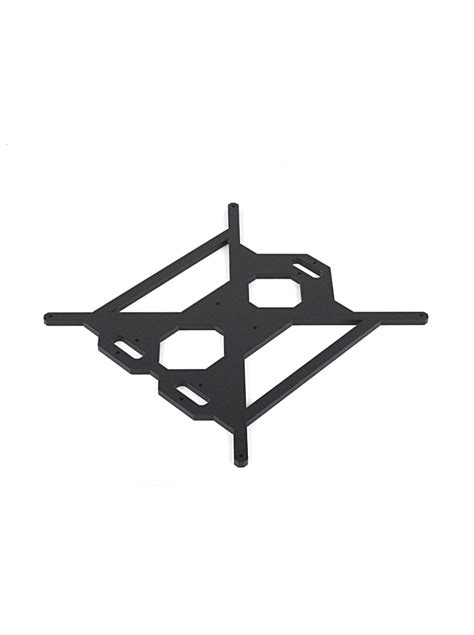

4. Printing with a Threaded Mold

A threaded mold is a specialized mold designed to create threaded panels. This mold is printed with a thread-shaped cavity that allows for precise and accurate printing of threads.

Advantages:

- High precision and accuracy

- Can be used with various materials

- No post-processing required

Disadvantages:

- Limited availability of threaded molds

- Can be expensive

5. Using a Hybrid Approach

A hybrid approach involves combining multiple methods to create threaded panels. For example, printing the panel with a hole and then using a threaded insert or printing with a threaded filament and then post-processing with a threaded nozzle.

Advantages:

- High precision and accuracy

- Can be used with various materials

- Flexible and adaptable

Disadvantages:

- Can be complex and time-consuming

- Requires additional post-processing steps

Conclusion

Creating threaded panels with precision and accuracy is a challenging task in 3D printing. However, by using one of the five methods outlined in this article, you can achieve perfect threaded panels. Whether you choose to use threaded inserts, print with threaded filaments, use a threaded nozzle, print with a threaded mold, or use a hybrid approach, the key to success lies in understanding the strengths and limitations of each method.

Table of Comparison

| Method | Advantages | Disadvantages |

|---|---|---|

| Threaded Inserts | Easy to implement, high precision and accuracy, can be used with various materials | Requires additional post-processing steps, can be expensive |

| Printing with Threaded Filaments | No post-processing required, high strength and precision, can be used with various printing technologies | Limited availability of threaded filaments, can be expensive |

| Using a Threaded Nozzle | High precision and accuracy, easy to implement, can be used with various materials | Limited availability of threaded nozzles, can be expensive |

| Printing with a Threaded Mold | High precision and accuracy, can be used with various materials, no post-processing required | Limited availability of threaded molds, can be expensive |

| Hybrid Approach | High precision and accuracy, can be used with various materials, flexible and adaptable | Can be complex and time-consuming, requires additional post-processing steps |

What is the most common method for creating threaded panels in 3D printing?

+

The most common method for creating threaded panels in 3D printing is using threaded inserts.

What is the advantage of using a threaded nozzle in 3D printing?

+

The advantage of using a threaded nozzle in 3D printing is high precision and accuracy, as well as ease of implementation.

Can I use a hybrid approach to create threaded panels in 3D printing?

+