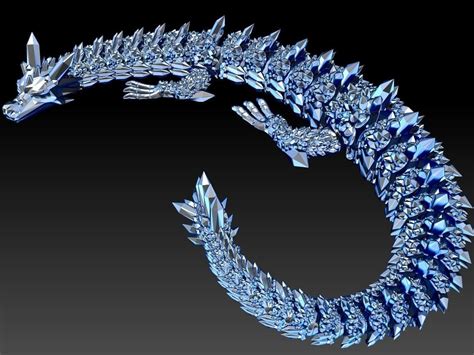

3D Print Flexible Tiger Designs Made Easy

Unlocking the World of Flexible 3D Printing: Creating Tiger Designs with Ease

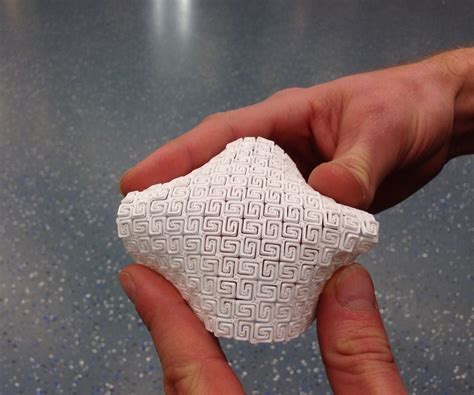

Flexible 3D printing has revolutionized the way we approach additive manufacturing, allowing for the creation of complex and intricate designs that were previously impossible to produce. One of the most exciting applications of flexible 3D printing is in the creation of animal designs, particularly those with complex textures and geometries like tigers. In this article, we’ll explore the world of flexible 3D printing and provide a step-by-step guide on how to create stunning tiger designs with ease.

Understanding Flexible 3D Printing

Flexible 3D printing involves the use of specialized filaments that can be bent, twisted, and shaped without breaking. These filaments are typically made from thermoplastic elastomers (TPEs) or thermoplastic polyurethanes (TPUs), which provide a unique combination of flexibility and strength. When used in conjunction with a 3D printer, these filaments can produce prints with intricate textures, complex geometries, and a wide range of flexibility levels.

Choosing the Right Filament for Your Tiger Design

When it comes to creating flexible tiger designs, the right filament is crucial. Here are some factors to consider when selecting a filament:

- Flexibility level: Tiger designs require a moderate level of flexibility to achieve the desired texture and movement. Look for filaments with a Shore hardness rating of 70-90A.

- Print resolution: A higher print resolution will result in a more detailed and realistic texture. Look for filaments with a high print resolution (e.g., 100-200 microns).

- Color options: Tiger designs often require a range of colors, from orange to black. Look for filaments that offer a wide range of color options or can be easily mixed to achieve the desired color.

Some popular flexible filaments for 3D printing include:

- Ninjaflex: A popular TPU-based filament with a Shore hardness rating of 85A.

- FlexPLA: A flexible PLA-based filament with a Shore hardness rating of 70A.

- TPU 95A: A high-strength TPU-based filament with a Shore hardness rating of 95A.

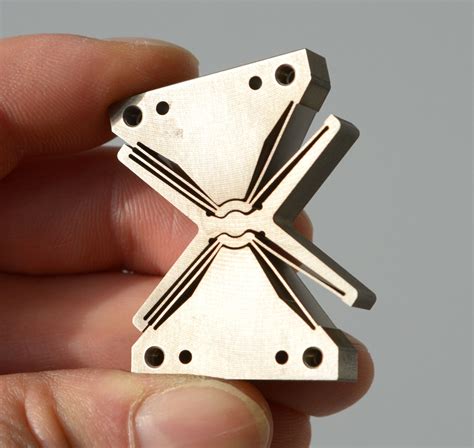

Designing Your Tiger Model

Once you’ve selected your filament, it’s time to design your tiger model. Here are some tips to keep in mind:

- Use a 3D modeling software: Software like Blender, Autodesk Maya, or Fusion 360 can help you create complex geometries and textures.

- Reference real-life tiger images: Study the texture, pattern, and shape of real-life tigers to achieve a realistic design.

- Keep it simple: Start with a simple design and gradually add complexity as you become more comfortable with the design process.

Here’s a simple tiger design to get you started:

| Component | Description |

|---|---|

| Body | A curved, cylindrical shape with a smooth texture |

| Legs | Four cylindrical shapes with a slightly rougher texture |

| Tail | A long, curved shape with a fluffy texture |

| Head | A rounded shape with a smooth texture and a distinctive tiger pattern |

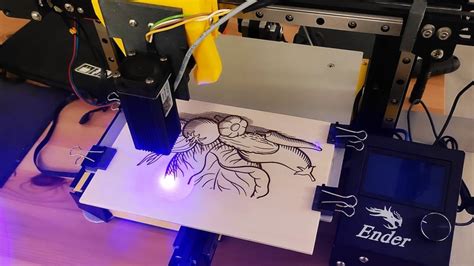

Printing Your Tiger Design

Once you’ve designed your tiger model, it’s time to print it. Here are some tips to keep in mind:

- Use a 3D printer with a flexible filament capability: Make sure your 3D printer can handle flexible filaments and has a heated bed to prevent warping.

- Adjust your print settings: Adjust your print settings to achieve the desired level of flexibility and texture. A higher infill density and slower print speed can help achieve a more realistic texture.

- Post-processing: Apply a gentle heat treatment or sanding to smooth out any rough edges or burrs.

💡 Note: When printing with flexible filaments, it's essential to adjust your print settings to prevent the filament from becoming too brittle or too flexible.

Assembling and Finishing Your Tiger Model

Once your tiger model is printed, it’s time to assemble and finish it. Here are some tips to keep in mind:

- Use a strong adhesive: Apply a strong adhesive, such as super glue or epoxy, to bond the different components together.

- Add details last: Add details, such as eyes or whiskers, last to prevent them from getting damaged during assembly.

- Apply a finish coat: Apply a finish coat, such as varnish or polyurethane, to protect the model from dust and damage.

What type of filament is best for creating flexible tiger designs?

+

A flexible filament with a Shore hardness rating of 70-90A, such as Ninjaflex or FlexPLA, is best for creating flexible tiger designs.

How do I achieve a realistic texture on my tiger design?

+

To achieve a realistic texture, use a 3D modeling software to create complex geometries and textures, and adjust your print settings to achieve the desired level of flexibility and texture.

What type of adhesive is best for assembling my tiger model?

+

A strong adhesive, such as super glue or epoxy, is best for assembling your tiger model.

With these tips and techniques, you can create stunning flexible tiger designs with ease. Remember to experiment with different filaments, print settings, and design techniques to achieve the desired level of flexibility and texture. Happy printing!