7 Ways to 3D Print Perfect Bottle Threads

Mastering the Art of 3D Printing Bottle Threads

3D printing has revolutionized the way we create and innovate, but it can be challenging to produce precise and functional parts, such as bottle threads. However, with the right techniques and strategies, you can achieve perfect bottle threads using your 3D printer. In this article, we will explore seven ways to 3D print perfect bottle threads, discussing the key considerations, design tips, and printing techniques to help you succeed.

Understanding the Importance of Thread Design

Before we dive into the printing process, it’s essential to understand the importance of thread design. A well-designed thread can make all the difference in the functionality and usability of your 3D printed bottle. Here are some key considerations to keep in mind:

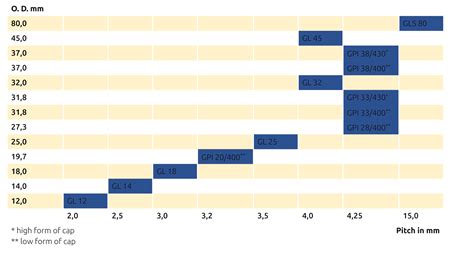

- Thread type: Decide on the type of thread you want to create, such as a standard screw thread or a more complex thread design.

- Thread pitch: The thread pitch refers to the distance between each thread. A smaller pitch results in a more precise thread, but may be more challenging to print.

- Thread depth: The thread depth affects the overall strength and stability of the thread. A deeper thread provides a stronger connection, but may be more difficult to print.

Design Tips for Perfect Bottle Threads

To create perfect bottle threads, you need to design your model with precision and attention to detail. Here are some design tips to help you get started:

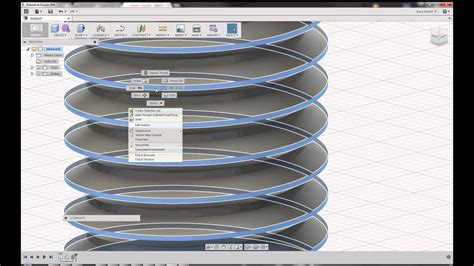

- Use a thread generator tool: Utilize online thread generator tools or software plugins to create accurate thread designs.

- Design for print orientation: Consider the print orientation of your model and design the thread accordingly.

- Add a thread chamfer: A thread chamfer helps to reduce stress concentrations and improves the overall strength of the thread.

7 Ways to 3D Print Perfect Bottle Threads

Now that we’ve covered the importance of thread design and design tips, let’s explore seven ways to 3D print perfect bottle threads:

1. Optimize Your Print Settings

Optimizing your print settings is crucial for producing high-quality bottle threads. Here are some key settings to adjust:

- Layer height: A lower layer height results in a more precise thread, but may increase print time.

- Infill density: A higher infill density provides a stronger thread, but may affect print speed.

- Support material: Use support material to prevent thread collapse and ensure accurate printing.

2. Use the Right Filament

The type of filament you use can significantly impact the quality of your bottle threads. Here are some popular filament options:

- PLA: A popular choice for 3D printing, PLA offers good strength and precision.

- ABS: ABS filament provides high impact resistance and is suitable for functional parts.

- PETG: PETG filament offers a balance of strength, precision, and affordability.

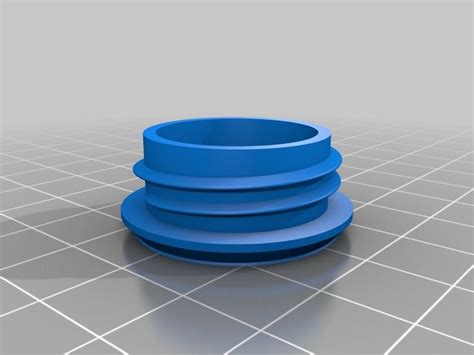

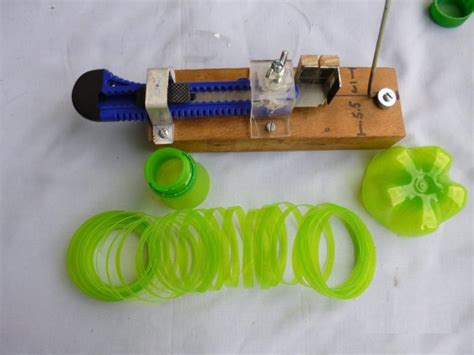

3. Implement a Thread Reinforcement

Reinforcing your thread design can improve its strength and stability. Here are some techniques to try:

- Add a thread reinforcement ring: A reinforcement ring provides additional support and strength to the thread.

- Use a thread reinforcement material: Incorporate a reinforcement material, such as carbon fiber or fiberglass, into your thread design.

4. Print with a High-Resolution Nozzle

Using a high-resolution nozzle can significantly improve the precision of your bottle threads. Here are some popular nozzle options:

- 0.2mm nozzle: A 0.2mm nozzle provides high precision and is suitable for small thread designs.

- 0.1mm nozzle: A 0.1mm nozzle offers even higher precision and is ideal for intricate thread designs.

5. Use a Thread-Specific Printing Technique

There are several printing techniques specifically designed for printing threads. Here are some popular options:

- Spiral printing: Spiral printing involves printing the thread in a spiral motion, reducing the risk of thread collapse.

- Helical printing: Helical printing involves printing the thread in a helical motion, providing high precision and accuracy.

6. Post-Processing Techniques

Post-processing techniques can enhance the quality and functionality of your bottle threads. Here are some popular options:

- Thread tapping: Thread tapping involves using a tap to create precise threads.

- Thread cutting: Thread cutting involves using a cutting tool to create precise threads.

7. Experiment and Iterate

Finally, don’t be afraid to experiment and iterate on your thread design and printing techniques. Here are some tips to keep in mind:

- Test different print settings: Experiment with different print settings to find the optimal configuration for your thread design.

- Refine your design: Refine your thread design based on the results of your print tests.

🤔 Note: Remember to always follow safety guidelines and best practices when working with 3D printing equipment and materials.

What is the best filament for printing bottle threads?

+

The best filament for printing bottle threads depends on the specific requirements of your project. PLA, ABS, and PETG are popular options, offering a balance of strength, precision, and affordability.

How do I prevent thread collapse during printing?

+

To prevent thread collapse, use support material, optimize your print settings, and implement a thread reinforcement technique.

What is the optimal layer height for printing bottle threads?

+

The optimal layer height for printing bottle threads depends on the specific requirements of your project. A lower layer height (e.g., 0.1mm) provides higher precision, but may increase print time.

By following these seven ways to 3D print perfect bottle threads, you’ll be well on your way to creating functional and precise parts for your projects. Remember to experiment, iterate, and refine your techniques to achieve the best possible results.