3D Printable Car Parts Revolutionize Automotive Repair

Revolutionizing Automotive Repair with 3D Printable Car Parts

The automotive industry is on the cusp of a revolution, thanks to the emergence of 3D printable car parts. This innovative technology is transforming the way car repairs are done, making it faster, cheaper, and more efficient. In this blog post, we will explore the world of 3D printable car parts, their benefits, and how they are changing the automotive repair landscape.

What are 3D Printable Car Parts?

3D printable car parts are spare parts that can be created using 3D printing technology. This technology uses a digital model to create a physical object, layer by layer, using a variety of materials such as plastics, metals, and ceramics. The resulting parts are strong, durable, and accurate, making them ideal for use in cars.

Benefits of 3D Printable Car Parts

There are several benefits to using 3D printable car parts:

- Faster Repair Times: With 3D printing, car parts can be created quickly, reducing repair times and getting cars back on the road faster.

- Cost Savings: 3D printing eliminates the need for tooling and molds, reducing the cost of production and making spare parts more affordable.

- Increased Customization: 3D printing allows for the creation of customized parts that can be tailored to specific cars and repair needs.

- Improved Quality: 3D printed parts can be designed with complex geometries and internal structures that cannot be produced using traditional manufacturing methods, resulting in stronger and more durable parts.

- Environmental Benefits: 3D printing reduces waste and energy consumption, making it a more sustainable option for car repairs.

Types of 3D Printable Car Parts

A wide range of car parts can be created using 3D printing, including:

- Interior parts: dashboards, trim, and other interior components

- Exterior parts: bumpers, spoilers, and other exterior components

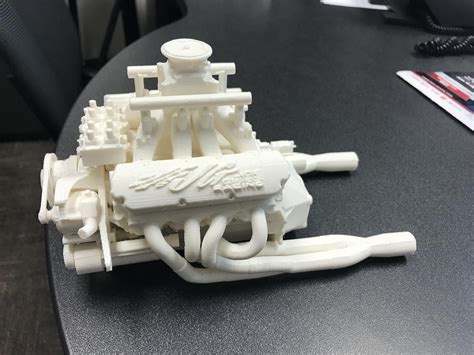

- Engine parts: engine mounts, intake manifolds, and other engine components

- Suspension parts: control arms, steering components, and other suspension parts

How 3D Printable Car Parts are Created

The process of creating 3D printable car parts involves several steps:

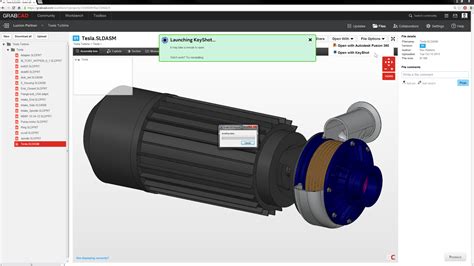

- Design: The part is designed using computer-aided design (CAD) software or other 3D modeling tools.

- Slicing: The design is sliced into layers, which are then sent to the 3D printer.

- Printing: The 3D printer creates the part, layer by layer, using a variety of materials such as plastics, metals, and ceramics.

- Post-processing: The part is removed from the printer and undergoes post-processing, which can include sanding, painting, and other finishing techniques.

🚨 Note: The quality of the 3D printed part depends on the type of material used, the printer's resolution, and the post-processing techniques employed.

Challenges and Limitations of 3D Printable Car Parts

While 3D printable car parts offer many benefits, there are also several challenges and limitations to consider:

- Material limitations: The range of materials available for 3D printing is limited, and some materials may not be suitable for certain applications.

- Scalability: 3D printing can be a slow process, making it challenging to produce large quantities of parts.

- Regulatory frameworks: There is a need for regulatory frameworks to ensure the safety and quality of 3D printed car parts.

Future of 3D Printable Car Parts

The future of 3D printable car parts is bright, with many car manufacturers and repair shops already embracing this technology. As the technology continues to evolve, we can expect to see:

- Increased adoption: More car manufacturers and repair shops will adopt 3D printing technology, leading to wider availability of 3D printable car parts.

- Improved materials: New materials will be developed, expanding the range of applications for 3D printed car parts.

- Increased customization: 3D printing will enable the creation of customized parts tailored to specific cars and repair needs.

The conclusion is clear: 3D printable car parts are revolutionizing the automotive repair industry, offering faster repair times, cost savings, and increased customization. As the technology continues to evolve, we can expect to see even more innovative applications of 3D printing in the automotive sector.

What are the benefits of using 3D printable car parts?

+

The benefits of using 3D printable car parts include faster repair times, cost savings, increased customization, improved quality, and environmental benefits.

What types of car parts can be created using 3D printing?

+

A wide range of car parts can be created using 3D printing, including interior parts, exterior parts, engine parts, and suspension parts.

What are the challenges and limitations of 3D printable car parts?

+

The challenges and limitations of 3D printable car parts include material limitations, scalability issues, and regulatory frameworks.

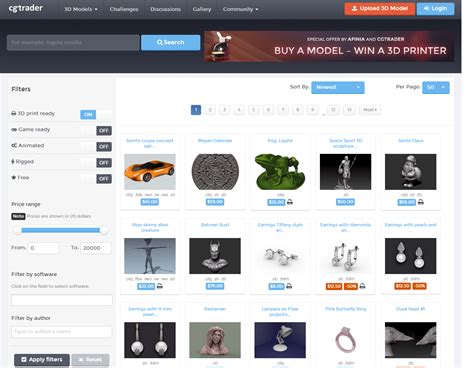

Related Terms:

- Thingiverse

- GrabCAD

- cults

- CGTrader

- Tinkercad

- MyMiniFactory 3D Print Files