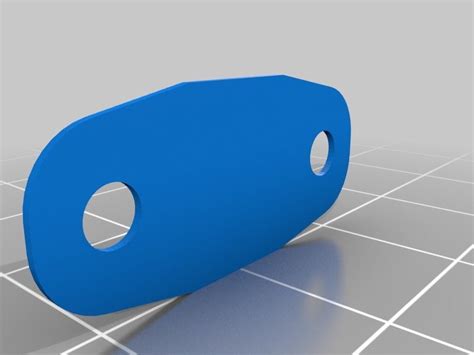

3D Printed Optical Adjuster for Precision and Customization

Introduction to 3D Printed Optical Adjusters

The world of optics has witnessed significant advancements in recent years, with 3D printing technology playing a crucial role in revolutionizing the field. One of the most exciting applications of 3D printing in optics is the creation of custom optical adjusters. These devices enable precise adjustments to optical systems, allowing for enhanced performance and customization. In this article, we will delve into the world of 3D printed optical adjusters, exploring their benefits, design considerations, and applications.

What are Optical Adjusters?

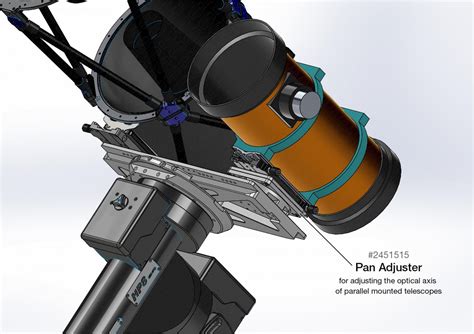

Optical adjusters are mechanical devices used to fine-tune the position and orientation of optical components, such as lenses, mirrors, and beamsplitters. These adjustments are critical in ensuring optimal performance in various optical systems, including telescopes, microscopes, and laser systems. Traditional optical adjusters are often limited by their design and material constraints, making it challenging to achieve precise adjustments.

Benefits of 3D Printed Optical Adjusters

3D printing technology offers several advantages in the creation of optical adjusters. Some of the key benefits include:

- Precision: 3D printing enables the creation of complex geometries and precise mechanisms, allowing for accurate adjustments.

- Customization: 3D printed optical adjusters can be tailored to specific applications, ensuring optimal performance.

- Rapid Prototyping: 3D printing allows for rapid prototyping and testing, reducing the time and cost associated with traditional manufacturing methods.

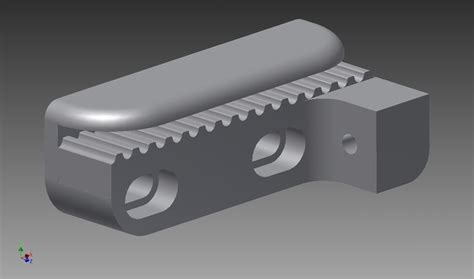

- Complex Geometries: 3D printing enables the creation of complex geometries and mechanisms that would be difficult or impossible to produce with traditional manufacturing methods.

Design Considerations for 3D Printed Optical Adjusters

When designing 3D printed optical adjusters, several factors must be considered to ensure optimal performance. Some of the key design considerations include:

- Material Selection: The choice of material is critical in ensuring the adjuster’s durability and precision. Common materials used include aluminum, stainless steel, and titanium.

- Mechanical Design: The mechanical design of the adjuster must be carefully considered to ensure smooth and precise adjustments.

- Optical Component Compatibility: The adjuster must be compatible with the optical components being used, ensuring proper alignment and positioning.

- Thermal Stability: The adjuster must be designed to maintain its precision and stability over a range of temperatures.

Applications of 3D Printed Optical Adjusters

3D printed optical adjusters have a wide range of applications in various fields, including:

- Telescope Optics: 3D printed optical adjusters can be used to fine-tune the position and orientation of telescope optics, enhancing image quality and resolution.

- Microscopy: 3D printed optical adjusters can be used to adjust the position and orientation of microscope optics, enabling high-resolution imaging.

- Laser Systems: 3D printed optical adjusters can be used to adjust the position and orientation of laser optics, ensuring optimal performance and beam quality.

🔍 Note: 3D printed optical adjusters can be used in a wide range of applications, including spectroscopy, interferometry, and optical metrology.

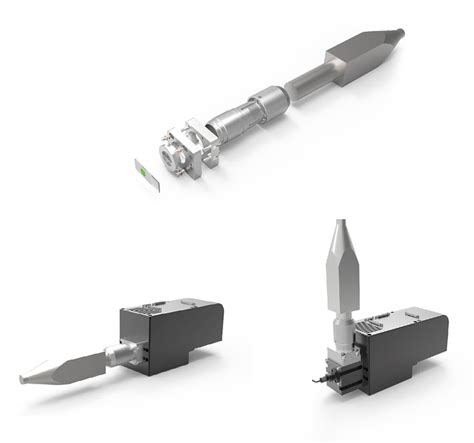

Creating a 3D Printed Optical Adjuster

Creating a 3D printed optical adjuster involves several steps, including:

- Design: Design the adjuster using computer-aided design (CAD) software, taking into account the design considerations mentioned earlier.

- Material Selection: Choose a suitable material for the adjuster, depending on the application and requirements.

- 3D Printing: Print the adjuster using a 3D printer, ensuring high accuracy and precision.

- Post-Processing: Perform any necessary post-processing, such as machining or assembly, to ensure optimal performance.

| Step | Description |

|---|---|

| 1. Design | Design the adjuster using CAD software |

| 2. Material Selection | Choose a suitable material for the adjuster |

| 3. 3D Printing | Print the adjuster using a 3D printer |

| 4. Post-Processing | Perform any necessary post-processing |

Conclusion

In conclusion, 3D printed optical adjusters offer a range of benefits, including precision, customization, rapid prototyping, and complex geometries. By considering the design considerations and applications mentioned in this article, engineers and researchers can create high-performance optical adjusters for a wide range of applications.

What is the main advantage of 3D printed optical adjusters?

+

The main advantage of 3D printed optical adjusters is their ability to provide precise adjustments and customization, enabling optimal performance in various optical systems.

What materials are commonly used for 3D printed optical adjusters?

+

Common materials used for 3D printed optical adjusters include aluminum, stainless steel, and titanium.

What is the typical process for creating a 3D printed optical adjuster?

+

The typical process involves designing the adjuster using CAD software, selecting a suitable material, 3D printing the adjuster, and performing any necessary post-processing.