Revolutionizing Workspaces: 3D Printed Tools for Modern Makers

Embracing the Future of Workspaces with 3D Printed Tools

The modern workspace is undergoing a significant transformation, driven by technological advancements and innovative solutions. One of the key drivers of this revolution is the integration of 3D printed tools, designed to enhance productivity, efficiency, and creativity. In this blog post, we will explore the world of 3D printed tools and their impact on modern makers.

What are 3D Printed Tools?

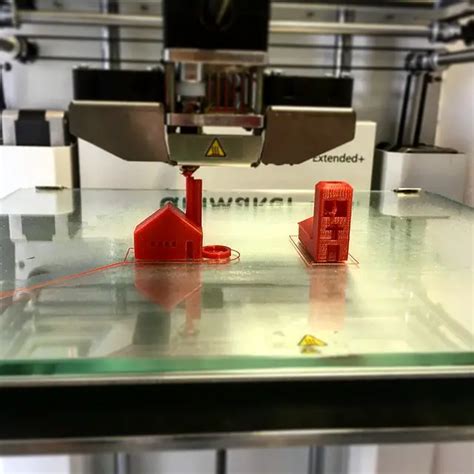

3D printed tools are objects created using additive manufacturing technology, also known as 3D printing. This process involves layering materials such as plastics, metals, or ceramics to create a physical object from a digital design. 3D printed tools can range from simple devices to complex machinery, offering a wide range of applications in various industries.

Benefits of 3D Printed Tools for Modern Makers

- Increased Efficiency: 3D printed tools enable makers to streamline their workflow, reducing the time and effort required to complete tasks.

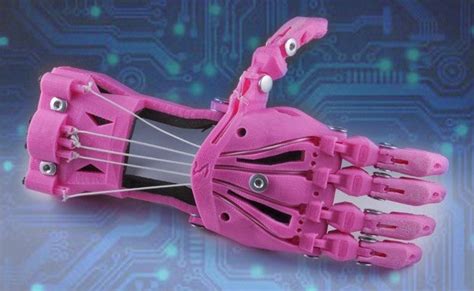

- Customization: 3D printed tools can be tailored to specific needs, allowing makers to create unique solutions that cater to their individual requirements.

- Cost-Effective: 3D printing technology eliminates the need for traditional manufacturing methods, reducing costs and making tool production more accessible.

- Improved Quality: 3D printed tools can be designed with complex geometries and structures, resulting in improved performance and durability.

Examples of 3D Printed Tools for Modern Makers

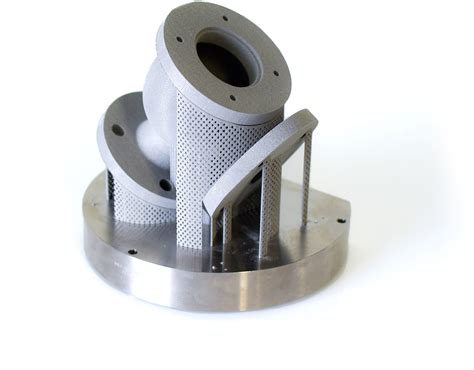

- Jigs and Fixtures: Custom-made jigs and fixtures can improve the accuracy and speed of assembly and manufacturing processes.

- Tool Handles: Ergonomic tool handles can be designed to fit individual preferences, reducing fatigue and improving comfort during use.

- Gadgets and Gizmos: Makers can create innovative gadgets and gizmos to simplify tasks, such as cable organizers or phone holders.

- Machine Parts: Replacement parts for machinery can be 3D printed, reducing downtime and increasing productivity.

Getting Started with 3D Printed Tools

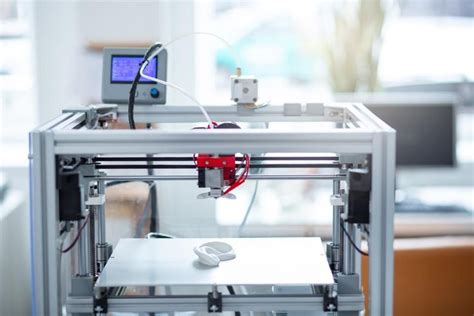

- Choose a 3D Printer: Select a suitable 3D printer that meets your needs and budget.

- Design Your Tool: Use computer-aided design (CAD) software or online tools to create a digital model of your desired tool.

- Select Materials: Choose a suitable material for your tool, considering factors such as durability, weight, and cost.

- Print and Refine: Print your tool and refine it as needed to achieve optimal performance.

🤔 Note: Ensure you follow proper safety protocols when working with 3D printed tools, as they may not meet traditional safety standards.

Case Study: Revolutionizing the Workspace with 3D Printed Tools

Meet Emma, a modern maker who owns a small woodworking business. Emma uses 3D printed tools to streamline her workflow and improve efficiency. She designed a custom jig to simplify the assembly of wooden furniture, reducing production time by 30%. Emma also created ergonomic tool handles that fit her preferences, reducing fatigue and improving comfort during use.

| Tool | Benefits |

|---|---|

| Custom Jig | Reduced production time by 30% |

| Ergonomic Tool Handles | Improved comfort and reduced fatigue |

Conclusion

3D printed tools are revolutionizing the modern workspace, offering makers a wide range of benefits, from increased efficiency to improved quality. By embracing this technology, makers can streamline their workflow, reduce costs, and create innovative solutions that cater to their individual needs.

What is the most common material used for 3D printed tools?

+

PLA (Polylactic Acid) is one of the most common materials used for 3D printed tools, due to its ease of use, affordability, and biodegradable properties.

Can I use 3D printed tools for heavy-duty applications?

+

While 3D printed tools can be designed for heavy-duty applications, they may not be suitable for extreme loads or stresses. It’s essential to test and refine your tools to ensure they meet your specific needs.

How do I ensure the quality of my 3D printed tools?

+

To ensure the quality of your 3D printed tools, it’s essential to use high-quality materials, calibrate your 3D printer regularly, and test your tools thoroughly before use.