Optimizing ABS Ironing with Orca Slicer Settings

Unlocking the Secrets of ABS Ironing: A Comprehensive Guide to Orca Slicer Settings

ABS ironing is a popular technique in 3D printing that involves using a heated bed and a special type of filament to create a smooth, glossy finish on the bottom layer of a print. However, achieving optimal results can be tricky, especially when it comes to configuring the Orca slicer settings. In this article, we’ll delve into the world of ABS ironing and explore the best practices for optimizing your Orca slicer settings to achieve stunning results.

Understanding ABS Ironing

Before we dive into the Orca slicer settings, it’s essential to understand the basics of ABS ironing. ABS ironing involves using a heated bed to melt the ABS filament, which is then smoothed out by a heated iron or a specialized tool. This process creates a smooth, glossy finish on the bottom layer of the print, eliminating the need for additional post-processing.

Benefits of ABS Ironing

- Improved aesthetics: ABS ironing creates a smooth, glossy finish that enhances the overall appearance of the print.

- Increased durability: The melted ABS filament forms a strong bond with the print bed, reducing the risk of warping or delamination.

- Reduced post-processing: ABS ironing eliminates the need for additional post-processing, such as sanding or applying a finish.

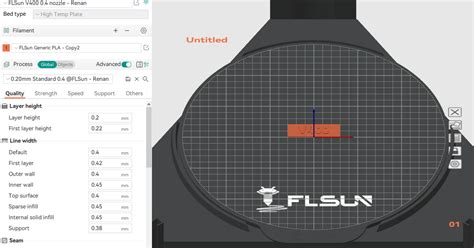

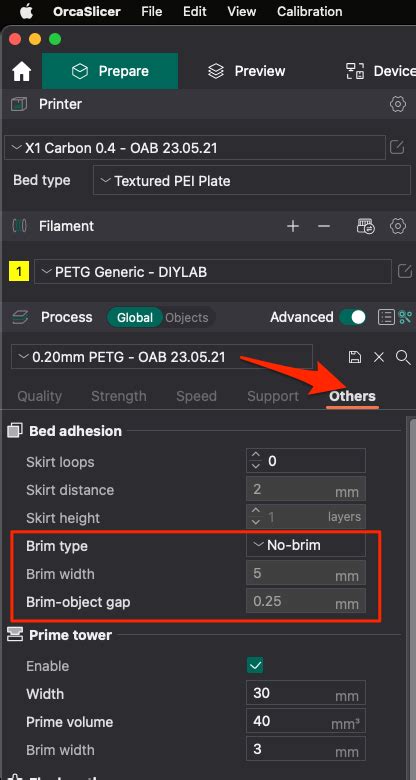

Optimizing Orca Slicer Settings for ABS Ironing

To achieve optimal results with ABS ironing, it’s crucial to configure your Orca slicer settings correctly. Here are some key settings to focus on:

- Layer height: A lower layer height will result in a smoother finish. Aim for a layer height of 0.1-0.2mm.

- Infill density: A higher infill density will provide better support for the ABS filament. Aim for an infill density of 20-30%.

- Wall thickness: A thicker wall will provide better support for the ABS filament. Aim for a wall thickness of 1.5-2mm.

- Top and bottom thickness: A thicker top and bottom layer will provide better support for the ABS filament. Aim for a top and bottom thickness of 1.5-2mm.

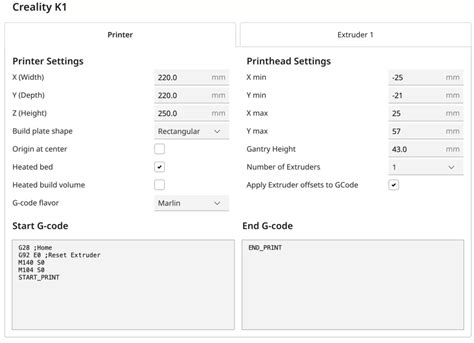

- Bed temperature: A higher bed temperature will help melt the ABS filament. Aim for a bed temperature of 100-110°C.

- Ironing temperature: A higher ironing temperature will help smooth out the ABS filament. Aim for an ironing temperature of 200-220°C.

🔥 Note: The optimal settings may vary depending on the specific ABS filament and print bed used. Experiment with different settings to find the optimal configuration for your setup.

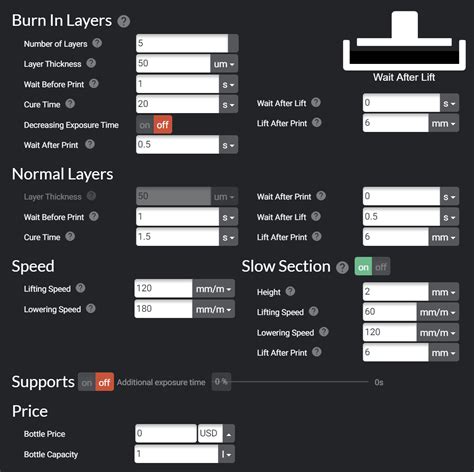

Advanced Orca Slicer Settings for ABS Ironing

In addition to the basic settings, there are several advanced settings that can further optimize your ABS ironing results. These include:

- Ironing pattern: Experiment with different ironing patterns, such as a grid or a spiral pattern, to find the optimal configuration for your print.

- Ironing speed: A slower ironing speed will provide a smoother finish. Aim for an ironing speed of 10-20mm/s.

- Ironing pressure: A higher ironing pressure will provide better support for the ABS filament. Aim for an ironing pressure of 10-20N.

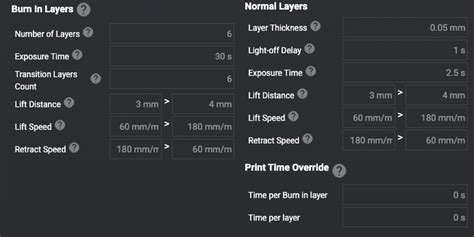

| Setting | Optimal Value | Description |

|---|---|---|

| Layer height | 0.1-0.2mm | A lower layer height will result in a smoother finish. |

| Infill density | 20-30% | A higher infill density will provide better support for the ABS filament. |

| Wall thickness | 1.5-2mm | A thicker wall will provide better support for the ABS filament. |

| Bed temperature | 100-110°C | A higher bed temperature will help melt the ABS filament. |

| Ironing temperature | 200-220°C | A higher ironing temperature will help smooth out the ABS filament. |

Conclusion

ABS ironing is a powerful technique for achieving a smooth, glossy finish on the bottom layer of a 3D print. By optimizing your Orca slicer settings, you can unlock the full potential of ABS ironing and create stunning prints. Remember to experiment with different settings to find the optimal configuration for your specific setup.

What is ABS ironing?

+

Abs ironing is a technique used in 3D printing to create a smooth, glossy finish on the bottom layer of a print. It involves using a heated bed and a special type of filament to melt the ABS filament, which is then smoothed out by a heated iron or a specialized tool.

What are the benefits of ABS ironing?

+

The benefits of ABS ironing include improved aesthetics, increased durability, and reduced post-processing. The smooth, glossy finish created by ABS ironing enhances the overall appearance of the print, while the melted ABS filament forms a strong bond with the print bed, reducing the risk of warping or delamination.

How do I optimize my Orca slicer settings for ABS ironing?

+

To optimize your Orca slicer settings for ABS ironing, focus on settings such as layer height, infill density, wall thickness, bed temperature, and ironing temperature. Experiment with different settings to find the optimal configuration for your specific setup.