8 Ways to Optimize Anet A8 Bowden Flow Rate

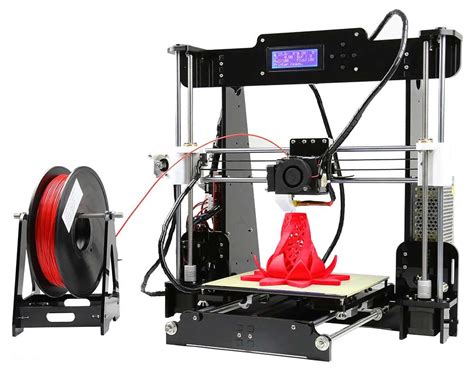

Understanding the Anet A8 Bowden Flow Rate

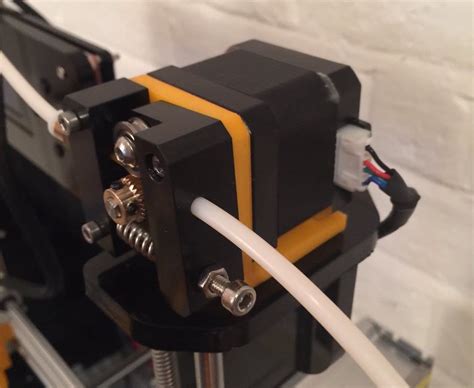

The Anet A8 is a popular 3D printer that uses a Bowden extruder system to deposit melted plastic onto a build plate. One of the key factors that affects the print quality of the Anet A8 is the flow rate of the extruder. A well-optimized flow rate can result in smooth, consistent prints, while a poorly optimized flow rate can lead to issues such as under-extrusion, over-extrusion, and poor layer adhesion.

In this article, we will explore 8 ways to optimize the Anet A8 Bowden flow rate, ensuring that you get the best possible prints from your machine.

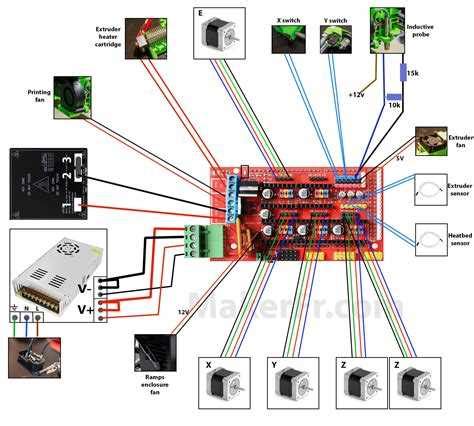

1. Calibrate the Extruder

Before optimizing the flow rate, it’s essential to calibrate the extruder. This involves adjusting the extruder’s steps per mm (steps/mm) value to match the actual distance that the filament travels. To do this:

- Measure the distance that the filament travels when the extruder is moved 100mm.

- Calculate the steps/mm value using the formula: steps/mm = (measured distance / 100mm) x default steps/mm value.

- Update the steps/mm value in your slicer software.

🔧 Note: Calibrating the extruder is a crucial step that ensures accurate flow rate calculations.

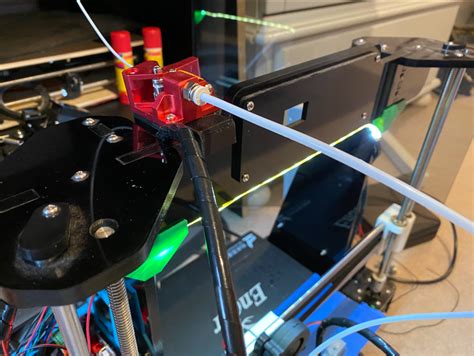

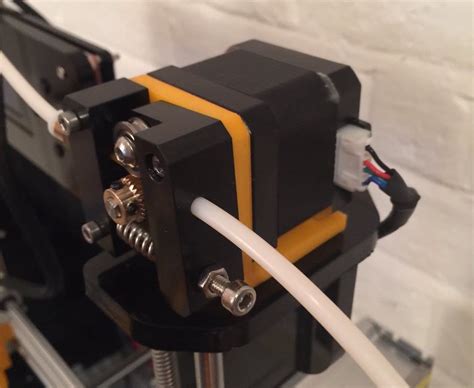

2. Adjust the Retraction Distance

Retraction distance refers to the amount of filament that is pulled back into the extruder when it’s not printing. Adjusting the retraction distance can help optimize the flow rate:

- Increase the retraction distance to reduce the amount of filament that oozes out during pauses.

- Decrease the retraction distance to prevent under-extrusion.

💡 Note: A retraction distance of 5-10mm is a good starting point.

3. Optimize the Extrusion Multiplier

The extrusion multiplier (EM) is a value that adjusts the amount of filament that’s extruded during printing. Optimizing the EM can help achieve the perfect flow rate:

- Increase the EM to increase the amount of filament extruded.

- Decrease the EM to decrease the amount of filament extruded.

📊 Note: A EM value of 1.0 is a good starting point.

4. Use a Pressure Advance (PA) Value

Pressure advance (PA) is a feature that adjusts the extruder’s pressure to compensate for the pressure drop during printing. Using a PA value can help optimize the flow rate:

- Increase the PA value to increase the pressure and reduce under-extrusion.

- Decrease the PA value to decrease the pressure and prevent over-extrusion.

🔩 Note: A PA value of 0.1-0.5 is a good starting point.

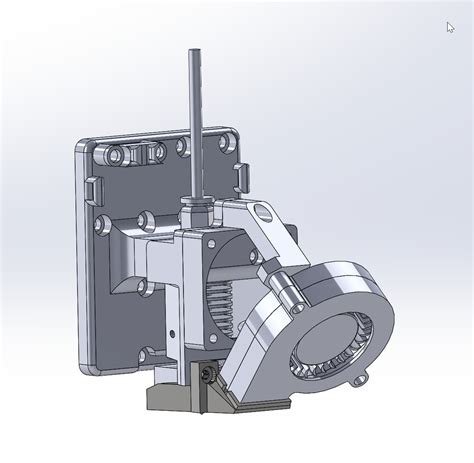

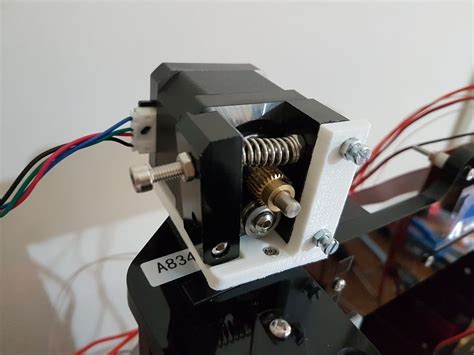

5. Upgrade to a High-Flow Hotend

Upgrading to a high-flow hotend can significantly improve the flow rate of the Anet A8. High-flow hotends are designed to handle higher temperatures and pressures, resulting in faster print speeds and improved print quality.

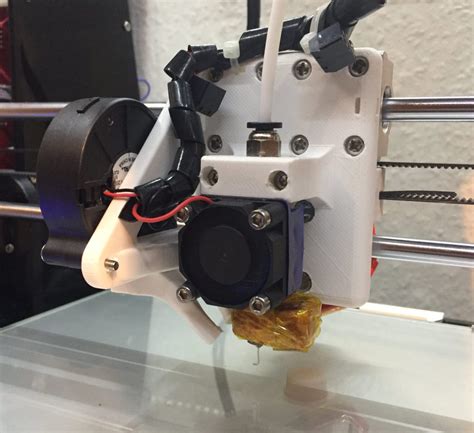

6. Use a High-Flow Nozzle

Using a high-flow nozzle can also improve the flow rate of the Anet A8. High-flow nozzles have a larger diameter, allowing for faster extrusion rates and improved print quality.

7. Adjust the Print Speed

Adjusting the print speed can also optimize the flow rate. Faster print speeds require higher extrusion rates, while slower print speeds require lower extrusion rates:

- Increase the print speed to increase the extrusion rate.

- Decrease the print speed to decrease the extrusion rate.

🚗 Note: A print speed of 50-100mm/s is a good starting point.

8. Monitor and Adjust

Finally, it’s essential to monitor and adjust the flow rate during printing. Keep an eye on the extruder’s temperature, pressure, and extrusion rate, and adjust as necessary to achieve the perfect flow rate.

| Flow Rate Optimization Method | Description |

|---|---|

| Calibrate the Extruder | Calibrate the extruder to ensure accurate flow rate calculations. |

| Adjust the Retraction Distance | Adjust the retraction distance to reduce oozing and prevent under-extrusion. |

| Optimize the Extrusion Multiplier | Optimize the extrusion multiplier to achieve the perfect flow rate. |

| Use a Pressure Advance (PA) Value | Use a PA value to adjust the extruder's pressure and optimize the flow rate. |

| Upgrade to a High-Flow Hotend | Upgrade to a high-flow hotend to improve the flow rate and print quality. |

| Use a High-Flow Nozzle | Use a high-flow nozzle to improve the flow rate and print quality. |

| Adjust the Print Speed | Adjust the print speed to optimize the flow rate. |

| Monitor and Adjust | Monitor and adjust the flow rate during printing to achieve the perfect flow rate. |

By following these 8 ways to optimize the Anet A8 Bowden flow rate, you can achieve smooth, consistent prints and improve the overall print quality of your machine.

Optimizing the flow rate of your Anet A8 is a crucial step in achieving high-quality prints. By calibrating the extruder, adjusting the retraction distance, optimizing the extrusion multiplier, using a pressure advance value, upgrading to a high-flow hotend, using a high-flow nozzle, adjusting the print speed, and monitoring and adjusting, you can achieve the perfect flow rate and take your prints to the next level.

What is the ideal flow rate for the Anet A8?

+

The ideal flow rate for the Anet A8 depends on the specific print settings and materials used. However, a flow rate of 50-100mm/s is a good starting point.

How do I calibrate the extruder on the Anet A8?

+

To calibrate the extruder on the Anet A8, measure the distance that the filament travels when the extruder is moved 100mm, and calculate the steps/mm value using the formula: steps/mm = (measured distance / 100mm) x default steps/mm value.

What is the difference between a high-flow hotend and a standard hotend?

+

A high-flow hotend is designed to handle higher temperatures and pressures, resulting in faster print speeds and improved print quality. A standard hotend, on the other hand, is designed for general-purpose printing and may not be able to handle high temperatures and pressures.