Bambu Lab 3D Printing Integration with Autodesk Fusion

Unlocking Seamless Design-to-Print Workflows with Bambu Lab 3D Printing Integration with Autodesk Fusion

The world of 3D printing has witnessed significant advancements in recent years, transforming the way designers, engineers, and manufacturers bring their ideas to life. At the forefront of this revolution is the integration of 3D printing technologies with powerful computer-aided design (CAD) software. One such integration that has been making waves in the industry is the Bambu Lab 3D printing integration with Autodesk Fusion. In this article, we will delve into the details of this integration, exploring its benefits, features, and how it can streamline your design-to-print workflows.

What is Autodesk Fusion?

Autodesk Fusion is a powerful CAD, computer-aided engineering (CAE), and computer-aided manufacturing (CAM) software that enables users to design, test, and fabricate innovative products. It offers a comprehensive set of tools for 3D modeling, simulation, and collaboration, making it an ideal platform for product development and manufacturing.

What is Bambu Lab 3D Printing?

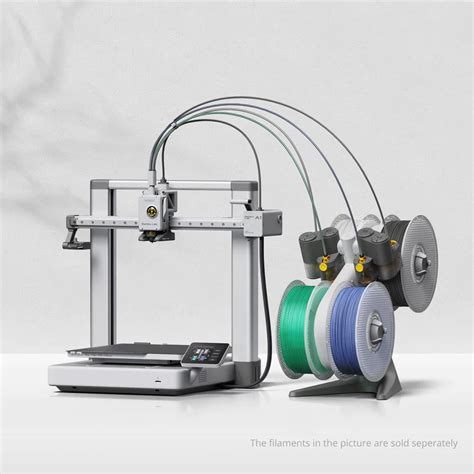

Bambu Lab is a cutting-edge 3D printing technology that offers unparalleled speed, precision, and reliability. Its innovative design and advanced features make it an attractive solution for a wide range of applications, from rapid prototyping to production-grade manufacturing.

Benefits of Bambu Lab 3D Printing Integration with Autodesk Fusion

The integration of Bambu Lab 3D printing with Autodesk Fusion offers numerous benefits, including:

- Seamless Design-to-Print Workflows: With this integration, users can design, simulate, and print their products within a single platform, eliminating the need for manual file transfers and reducing the risk of errors.

- Streamlined Production: The integration enables users to optimize their print settings and monitor the printing process in real-time, ensuring that their products are manufactured efficiently and accurately.

- Improved Product Quality: By leveraging the advanced simulation tools in Autodesk Fusion, users can test and validate their designs before printing, reducing the likelihood of defects and improving overall product quality.

Key Features of Bambu Lab 3D Printing Integration with Autodesk Fusion

Some of the key features of this integration include:

- Direct Print Interface: Users can print their designs directly from Autodesk Fusion, eliminating the need for manual file exports and imports.

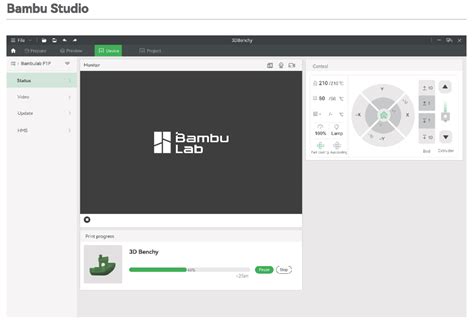

- Real-Time Print Monitoring: Users can monitor the printing process in real-time, allowing them to identify and address any issues promptly.

- Advanced Print Settings: Users can optimize their print settings, including layer thickness, infill density, and support structures, to achieve the desired level of quality and accuracy.

- Simulation and Validation: Users can simulate and validate their designs before printing, ensuring that their products meet the required specifications and performance criteria.

How to Get Started with Bambu Lab 3D Printing Integration with Autodesk Fusion

To get started with this integration, follow these steps:

- Install Autodesk Fusion: Download and install Autodesk Fusion on your computer.

- Install Bambu Lab 3D Printing Software: Download and install the Bambu Lab 3D printing software on your computer.

- Configure the Integration: Configure the integration by following the instructions provided in the Autodesk Fusion and Bambu Lab documentation.

- Design and Print: Design your product in Autodesk Fusion and print it directly using the Bambu Lab 3D printing integration.

📝 Note: Ensure that you have the latest versions of Autodesk Fusion and Bambu Lab 3D printing software installed to take advantage of the integration features.

Conclusion

The integration of Bambu Lab 3D printing with Autodesk Fusion offers a powerful solution for designers, engineers, and manufacturers who want to streamline their design-to-print workflows. By leveraging the advanced features and benefits of this integration, users can improve product quality, reduce production time, and increase overall efficiency.

What are the system requirements for the Bambu Lab 3D printing integration with Autodesk Fusion?

+

The system requirements for the integration include a computer with a minimum of 8 GB RAM, a 64-bit operating system, and a compatible graphics card.

Can I use the Bambu Lab 3D printing integration with other CAD software?

+

No, the Bambu Lab 3D printing integration is currently only compatible with Autodesk Fusion.

What types of materials can I print with the Bambu Lab 3D printing integration?

+

The Bambu Lab 3D printing integration supports a wide range of materials, including plastics, metals, and ceramics.