Caliper Measuring Tool: A Precise Measurement Companion

Understanding the Importance of Precise Measurements

In various industries, including engineering, manufacturing, and construction, precise measurements are crucial for achieving desired outcomes. One tool that has been instrumental in facilitating accurate measurements is the caliper measuring tool. This versatile device has been a trusted companion for professionals and enthusiasts alike, providing reliable measurements in a wide range of applications.

What is a Caliper Measuring Tool?

A caliper measuring tool is a precision instrument used to measure the distance between two points or the width of an object. It typically consists of a main scale, a vernier scale, and a movable jaw that can be adjusted to fit around the object being measured. Calipers are available in different types, including digital, dial, and vernier calipers, each with its unique features and advantages.

Types of Caliper Measuring Tools

There are several types of caliper measuring tools, each designed to cater to specific measurement needs. Some of the most common types include:

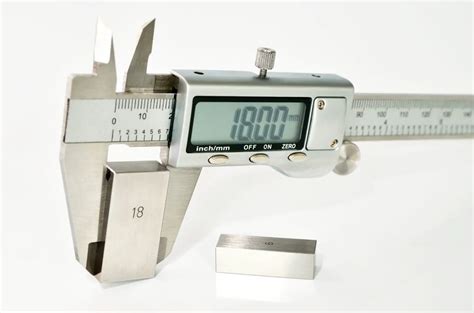

- Digital Calipers: These calipers use electronic sensors to display measurements on an LCD screen. They offer high accuracy and are often used in precision engineering and manufacturing applications.

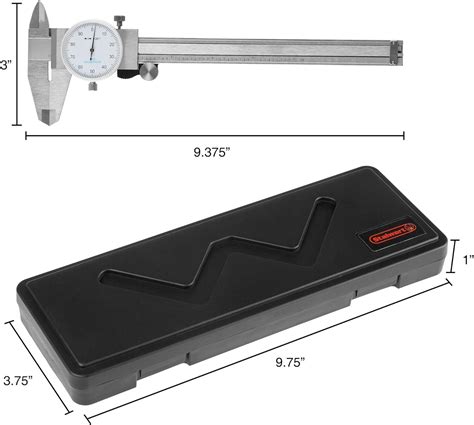

- Dial Calipers: These calipers use a rotating dial to display measurements. They are commonly used in machine shops and are known for their ease of use and high accuracy.

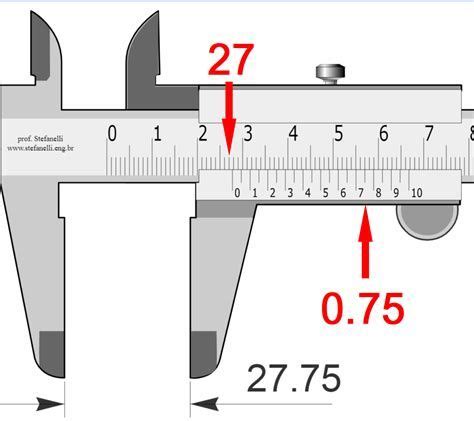

- Vernier Calipers: These calipers use a vernier scale to measure small increments. They are often used in applications where high precision is required, such as in laboratory settings.

How to Use a Caliper Measuring Tool

Using a caliper measuring tool is relatively straightforward. Here’s a step-by-step guide to get you started:

- Choose the correct type of caliper for your measurement needs.

- Ensure the caliper is properly calibrated and adjusted.

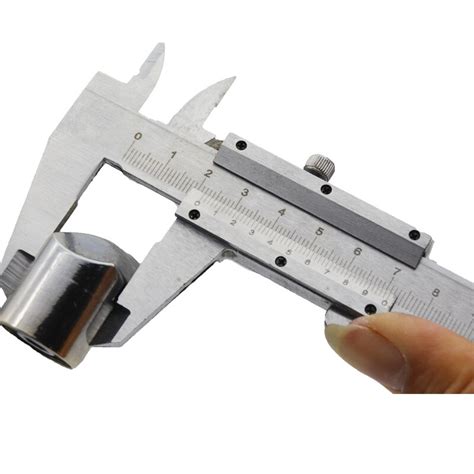

- Place the object to be measured between the jaws of the caliper.

- Adjust the movable jaw to fit snugly around the object.

- Read the measurement from the main scale and vernier scale (if applicable).

- Record the measurement and repeat as necessary.

🔍 Note: Always handle calipers with care, as they are precision instruments and can be damaged easily.

Benefits of Using a Caliper Measuring Tool

Caliper measuring tools offer numerous benefits, including:

- High Accuracy: Calipers provide precise measurements, reducing errors and improving overall quality.

- Versatility: Calipers can be used in various applications, from engineering and manufacturing to construction and laboratory settings.

- Ease of Use: Calipers are relatively easy to use, even for those without extensive measurement experience.

Applications of Caliper Measuring Tools

Caliper measuring tools are used in a wide range of applications, including:

- Engineering: Calipers are used to measure components and ensure precise fit and function.

- Manufacturing: Calipers are used to measure parts and ensure quality control.

- Construction: Calipers are used to measure materials and ensure accurate cuts and fits.

| Industry | Application |

|---|---|

| Engineering | Component measurement and inspection |

| Manufacturing | Quality control and part measurement |

| Construction | Material measurement and cutting |

Conclusion

In conclusion, caliper measuring tools are essential instruments for achieving precise measurements in various industries. With their high accuracy, versatility, and ease of use, calipers have become a trusted companion for professionals and enthusiasts alike. By understanding the different types of calipers and their applications, individuals can choose the right tool for their measurement needs and achieve desired outcomes.

What is the difference between a digital caliper and a dial caliper?

+

Digital calipers use electronic sensors to display measurements on an LCD screen, while dial calipers use a rotating dial to display measurements. Digital calipers are often more accurate and easier to use, but dial calipers are often more affordable and suitable for basic measurement needs.

How do I calibrate my caliper measuring tool?

+

To calibrate your caliper measuring tool, refer to the manufacturer’s instructions. Typically, you will need to adjust the main scale and vernier scale to ensure accurate measurements. You may also need to perform a zero-error adjustment to ensure the caliper is properly calibrated.

What is the most common type of caliper measuring tool used in industry?

+

Digital calipers are the most common type of caliper measuring tool used in industry, due to their high accuracy and ease of use. They are widely used in engineering, manufacturing, and construction applications.