Cutting EMT Pipe: A Guide to Making Clean Cuts

Cutting EMT Pipe: A Guide to Making Clean Cuts

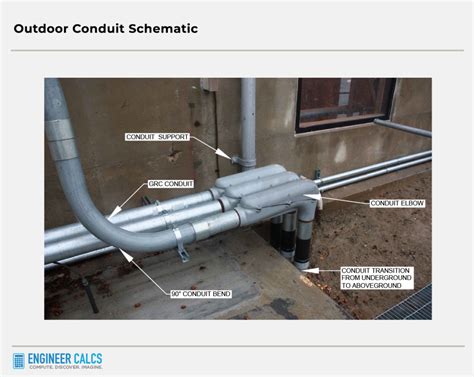

Cutting EMT (Electrical Metallic Tubing) pipe is a crucial step in many electrical projects. Whether you’re a professional electrician or a DIY enthusiast, making clean cuts is essential for ensuring a safe and efficient installation. In this guide, we’ll walk you through the different methods for cutting EMT pipe, including the tools and techniques you’ll need to get the job done.

Choosing the Right Tool

Before you start cutting your EMT pipe, you’ll need to choose the right tool for the job. There are several options available, each with its own advantages and disadvantages.

- Pipe cutter: A pipe cutter is a specialized tool designed specifically for cutting pipes. It works by scoring the pipe and then breaking it off, leaving a clean cut. Pipe cutters are available in various sizes to accommodate different pipe diameters.

- Hacksaw: A hacksaw is a versatile tool that can be used to cut a variety of materials, including EMT pipe. While it may not be as precise as a pipe cutter, a hacksaw can still produce a clean cut with a little practice.

- Reciprocating saw: A reciprocating saw, also known as a Sawzall, is a powerful tool that can be used to cut through EMT pipe quickly and efficiently. However, it may not be the best choice for smaller pipes or for making precise cuts.

Preparing the Pipe

Before you start cutting your EMT pipe, make sure it’s properly prepared. Here are a few steps to follow:

- Clean the pipe: Make sure the pipe is free of debris and dirt. This will help ensure a clean cut and prevent any obstructions.

- Measure the pipe: Measure the length of pipe you need to cut, taking into account any fittings or connectors that will be attached.

- Mark the pipe: Use a marker or a piece of tape to mark the cut line on the pipe.

Cutting the Pipe

Now that you’ve chosen your tool and prepared the pipe, it’s time to make the cut. Here are the steps to follow for each of the tools mentioned above:

- Pipe cutter:

- Place the pipe cutter on the marked cut line.

- Tighten the cutter by turning the handle clockwise.

- Continue to tighten the cutter until the pipe breaks off.

- Hacksaw:

- Place the hacksaw blade on the marked cut line.

- Start sawing slowly and steadily, using a gentle back-and-forth motion.

- Continue sawing until the pipe is cut through.

- Reciprocating saw:

- Place the saw blade on the marked cut line.

- Start the saw and slowly begin to cut through the pipe.

- Continue cutting until the pipe is severed.

🔧 Note: When using a reciprocating saw, make sure to wear safety goggles and keep loose clothing tied back to avoid injury.

Deburring the Cut

After making the cut, you’ll need to deburr the pipe to remove any sharp edges or debris. Here are the steps to follow:

- Use a deburring tool: A deburring tool is a specialized tool designed specifically for removing sharp edges and debris from cut pipes.

- Use a file: A file can be used to smooth out any rough edges or burrs on the pipe.

- Use sandpaper: Sandpaper can be used to smooth out any rough edges or burrs on the pipe.

Inspection and Testing

After cutting and deburring the pipe, it’s essential to inspect and test it to ensure it’s safe and functional. Here are the steps to follow:

- Inspect the pipe: Visually inspect the pipe for any signs of damage or defects.

- Test the pipe: Use a pressure test to ensure the pipe is leak-free and functional.

Tips and Tricks

Here are a few tips and tricks to keep in mind when cutting EMT pipe:

- Use a pipe cutter for precise cuts: A pipe cutter is the best tool for making precise cuts on EMT pipe.

- Use a hacksaw for larger pipes: A hacksaw is a good option for cutting larger pipes, but it may not be as precise as a pipe cutter.

- Use a reciprocating saw for speed: A reciprocating saw is the best tool for cutting through EMT pipe quickly, but it may not be as precise as a pipe cutter or hacksaw.

Common Mistakes to Avoid

Here are a few common mistakes to avoid when cutting EMT pipe:

- Cutting too slowly: Cutting too slowly can cause the pipe to become damaged or deformed.

- Cutting too quickly: Cutting too quickly can cause the pipe to become rough or uneven.

- Not deburring the pipe: Not deburring the pipe can cause sharp edges or debris to remain, which can be hazardous.

Conclusion

Cutting EMT pipe is a crucial step in many electrical projects. By choosing the right tool, preparing the pipe, and following the correct techniques, you can make clean cuts and ensure a safe and efficient installation. Remember to inspect and test the pipe after cutting and deburring to ensure it’s safe and functional.

What is the best tool for cutting EMT pipe?

+

The best tool for cutting EMT pipe depends on the size of the pipe and the desired level of precision. A pipe cutter is the best tool for making precise cuts, while a hacksaw is a good option for cutting larger pipes. A reciprocating saw is the best tool for cutting through EMT pipe quickly.

How do I deburr the cut pipe?

+

Deburring the cut pipe can be done using a deburring tool, a file, or sandpaper. A deburring tool is the best option for removing sharp edges and debris from cut pipes.

What are the common mistakes to avoid when cutting EMT pipe?

+

Common mistakes to avoid when cutting EMT pipe include cutting too slowly, cutting too quickly, and not deburring the pipe. Cutting too slowly can cause the pipe to become damaged or deformed, while cutting too quickly can cause the pipe to become rough or uneven. Not deburring the pipe can cause sharp edges or debris to remain, which can be hazardous.