5 Tips for Using a Delta Drill Press

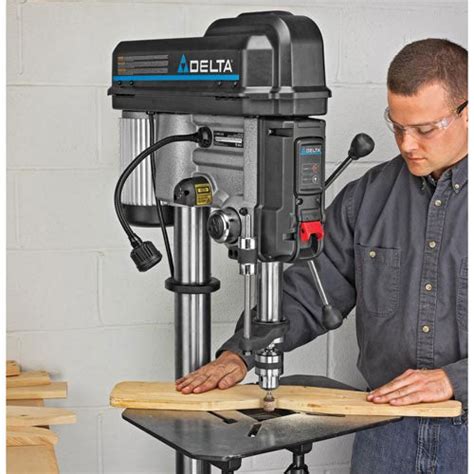

Unlocking the Full Potential of Your Delta Drill Press

A Delta drill press is a powerful and versatile tool that can be used for a variety of tasks, from drilling precise holes to driving large screws. However, to get the most out of your drill press, you need to know how to use it effectively. Here are five tips to help you unlock the full potential of your Delta drill press.

Tip 1: Choose the Right Drill Bit

One of the most critical factors in getting the best results from your Delta drill press is choosing the right drill bit. With so many different types of drill bits available, it can be overwhelming to decide which one to use. Here are a few things to consider when selecting a drill bit:

- Material: Different materials require different types of drill bits. For example, if you’re drilling through metal, you’ll need a bit with a tungsten carbide tip. If you’re drilling through wood, a high-speed steel bit will suffice.

- Size: Make sure to choose a drill bit that’s the right size for the job. A bit that’s too small may not provide enough torque, while a bit that’s too large may be difficult to control.

- Type: There are several types of drill bits, including twist bits, spade bits, and hole saws. Twist bits are the most common type and are used for general-purpose drilling. Spade bits are used for large holes and hole saws are used for drilling precise circles.

🔩 Note: Always use a sharp drill bit to ensure accurate and efficient drilling.

Tip 2: Set Up Your Drill Press Correctly

Before you start drilling, make sure your Delta drill press is set up correctly. Here are a few things to check:

- Table height: Make sure the table is at the correct height for the job. If the table is too high or too low, it can be difficult to control the drill bit.

- Drill bit alignment: Make sure the drill bit is aligned properly with the workpiece. If the bit is not aligned correctly, it can cause the drill press to bind or kickback.

- Clamping: Make sure the workpiece is clamped securely to the table. This will help prevent the workpiece from moving during drilling.

Tip 3: Use the Correct Drilling Speed

Using the correct drilling speed is critical for getting accurate and efficient results from your Delta drill press. Here are a few things to consider:

- Material: Different materials require different drilling speeds. For example, if you’re drilling through metal, you’ll need to use a slower speed than if you’re drilling through wood.

- Drill bit size: The size of the drill bit also affects the drilling speed. Larger bits require slower speeds, while smaller bits can be drilled at faster speeds.

| Material | Drill Bit Size | Drilling Speed |

|---|---|---|

| Metal | 1/8 inch | 500-1000 RPM |

| Wood | 1/4 inch | 1000-2000 RPM |

| Plastic | 1/2 inch | 2000-3000 RPM |

Tip 4: Use a Drill Press Vice

A drill press vice is a handy accessory that can help you hold your workpiece securely in place while drilling. Here are a few benefits of using a drill press vice:

- Improved accuracy: A drill press vice helps to keep the workpiece steady, which improves the accuracy of your drilling.

- Increased safety: A drill press vice helps to prevent the workpiece from moving during drilling, which reduces the risk of injury.

- Reduced damage: A drill press vice helps to prevent damage to the workpiece and the drill press itself.

Tip 5: Maintain Your Drill Press Regularly

Regular maintenance is critical for keeping your Delta drill press running smoothly and efficiently. Here are a few things to check:

- Lubrication: Make sure to lubricate the drill press regularly to keep the moving parts running smoothly.

- Tightening: Check the drill press regularly to make sure all the parts are tightened securely.

- Cleaning: Clean the drill press regularly to remove dirt and debris that can affect its performance.

By following these five tips, you can unlock the full potential of your Delta drill press and get the most out of your woodworking and metalworking projects.

Summary of key points: Choose the right drill bit, set up your drill press correctly, use the correct drilling speed, use a drill press vice, and maintain your drill press regularly.

What is the best type of drill bit for drilling through metal?

+

A tungsten carbide tip drill bit is the best type of drill bit for drilling through metal.

How often should I lubricate my drill press?

+

You should lubricate your drill press regularly, ideally every 1-2 months, depending on usage.

What is the purpose of a drill press vice?

+

A drill press vice is used to hold the workpiece securely in place while drilling, improving accuracy and safety.