Best Drill Size for Tapping 1/4-20 Threads

Choosing the Right Drill Size for Tapping 1/4-20 Threads

When it comes to tapping threads, selecting the correct drill size is crucial for achieving accurate and reliable results. The 1⁄4-20 thread is a common thread size used in various applications, including construction, automotive, and industrial manufacturing. In this article, we will explore the best drill size for tapping 1⁄4-20 threads and provide valuable insights to help you make informed decisions.

Understanding Thread Tapping

Thread tapping is a process that involves creating internal threads in a material, typically metal, using a tap. The tap is a cutting tool designed to remove material and create the desired thread pattern. To ensure successful thread tapping, it’s essential to choose the correct drill size, which serves as a pilot hole for the tap.

Drill Size Selection for 1/4-20 Threads

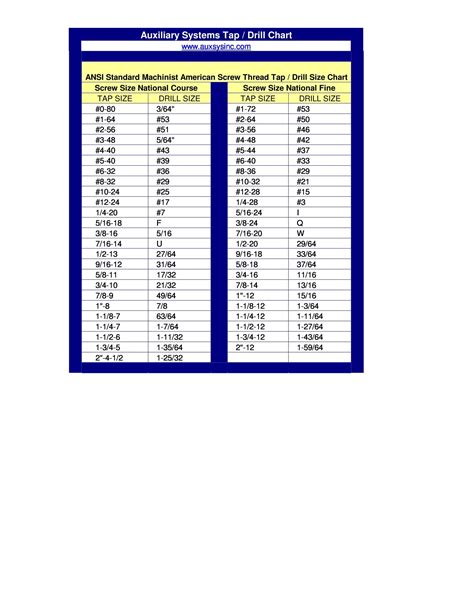

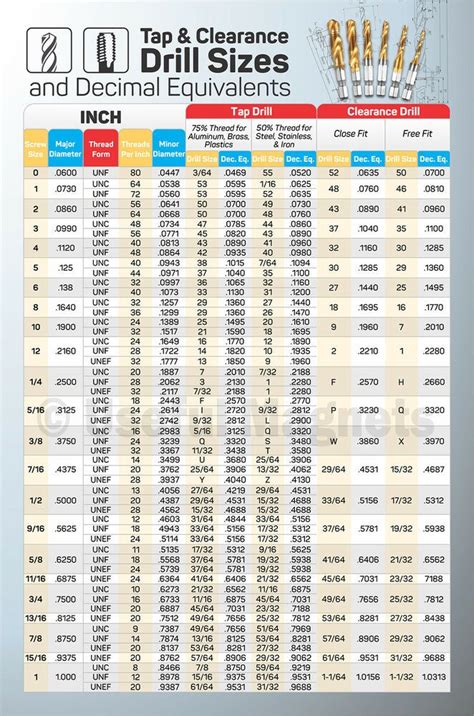

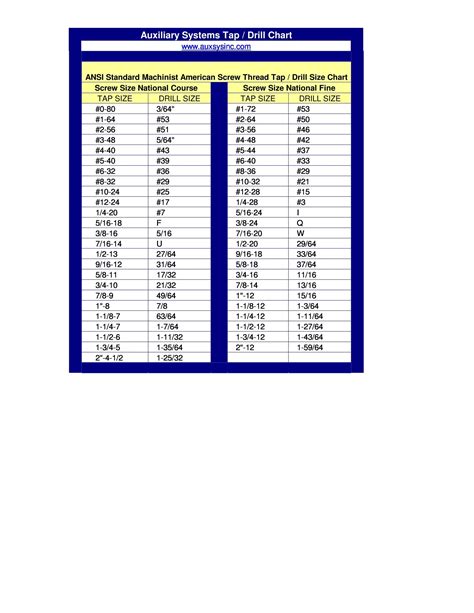

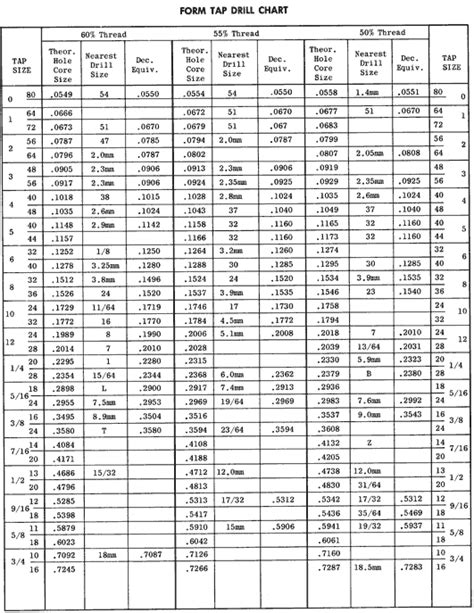

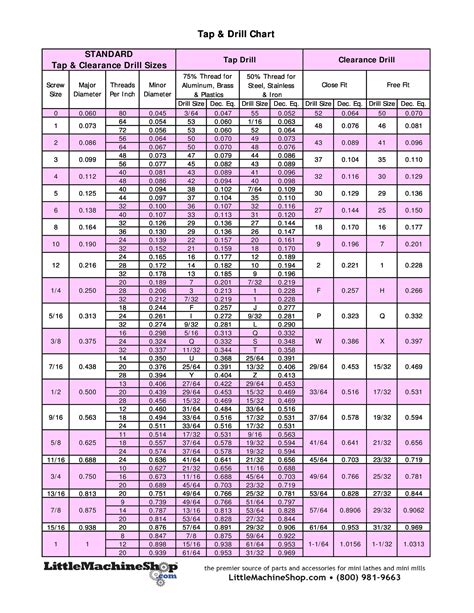

The ideal drill size for tapping 1⁄4-20 threads depends on the material being tapped and the desired thread quality. Here are some general guidelines for selecting the best drill size:

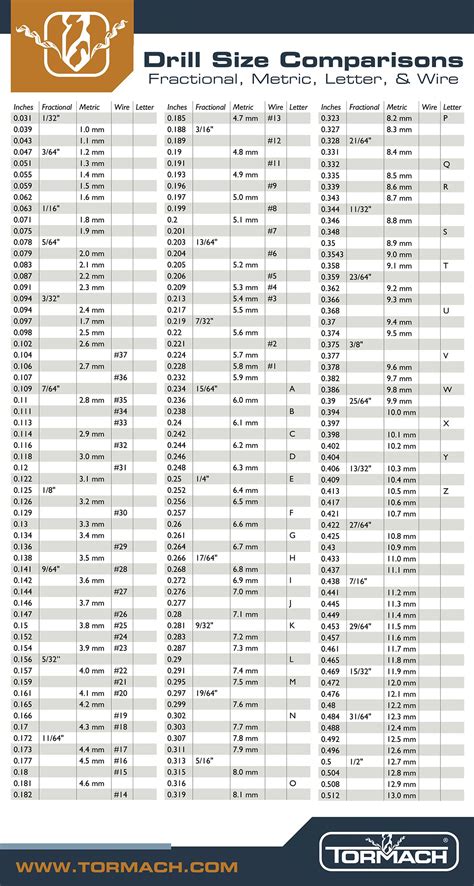

- For soft materials like aluminum, brass, or copper, use a drill size that is 1⁄16 inch smaller than the tap size. For 1⁄4-20 threads, this would be a #7 drill bit (0.201 inches).

- For medium-hard materials like steel or stainless steel, use a drill size that is 1⁄32 inch smaller than the tap size. For 1⁄4-20 threads, this would be a #10 drill bit (0.193 inches).

- For hard materials like titanium or hardened steel, use a drill size that is 1⁄64 inch smaller than the tap size. For 1⁄4-20 threads, this would be a #12 drill bit (0.189 inches).

💡 Note: These are general guidelines and may vary depending on the specific application and material properties.

Factors Affecting Drill Size Selection

Several factors can influence the choice of drill size for tapping 1⁄4-20 threads, including:

- Material hardness and density

- Thread quality requirements (e.g., Class 2 or Class 3)

- Tap type (e.g., straight flute or spiral flute)

- Tapping speed and feed rate

Drill Bit Types and Materials

The type and material of the drill bit can also impact the tapping process. Here are some common drill bit types and materials:

- High-speed steel (HSS) drill bits: Suitable for most tapping applications, offering a good balance of hardness and toughness.

- Cobalt drill bits: More wear-resistant than HSS, ideal for tapping hard materials or high-volume production.

- Carbide drill bits: Extremely hard and wear-resistant, often used for tapping very hard materials or in high-precision applications.

Tapping Techniques and Best Practices

To ensure successful tapping, follow these techniques and best practices:

- Use a center drill or spotting drill to create a precise pilot hole.

- Apply the correct tapping speed and feed rate for the material and tap type.

- Maintain proper tap alignment and ensure the tap is perpendicular to the workpiece.

- Use a tapping fluid or lubricant to reduce friction and prevent tap breakage.

Conclusion

Choosing the correct drill size for tapping 1⁄4-20 threads is critical for achieving accurate and reliable results. By considering the material properties, thread quality requirements, and tap type, you can select the best drill size for your application. Remember to also follow proper tapping techniques and best practices to ensure successful thread tapping.

What is the recommended drill size for tapping 1⁄4-20 threads in aluminum?

+

A #7 drill bit (0.201 inches) is recommended for tapping 1⁄4-20 threads in aluminum.

What factors affect the choice of drill size for tapping 1⁄4-20 threads?

+

Material hardness and density, thread quality requirements, tap type, and tapping speed and feed rate can all impact the choice of drill size.

What is the difference between HSS and carbide drill bits?

+

HSS drill bits are suitable for most tapping applications, while carbide drill bits are extremely hard and wear-resistant, often used for tapping very hard materials or in high-precision applications.