7 Ways to Optimize Drill Tip Angle for Best Results

Understanding the Importance of Drill Tip Angle

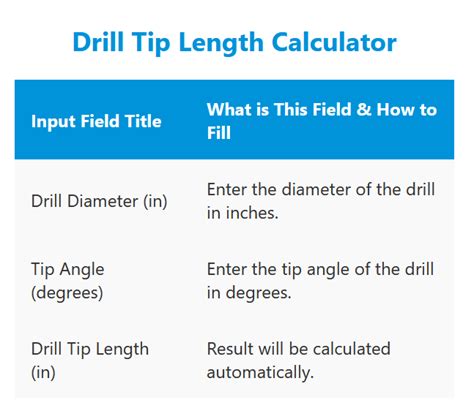

When it comes to drilling, the tip angle of the drill bit plays a crucial role in determining the efficiency and effectiveness of the process. The drill tip angle refers to the angle at which the drill bit cuts into the material being drilled. A well-optimized drill tip angle can result in faster drilling times, improved hole quality, and reduced wear on the drill bit.

Factors Affecting Drill Tip Angle

Before we dive into the ways to optimize drill tip angle, it’s essential to understand the factors that affect it. These include:

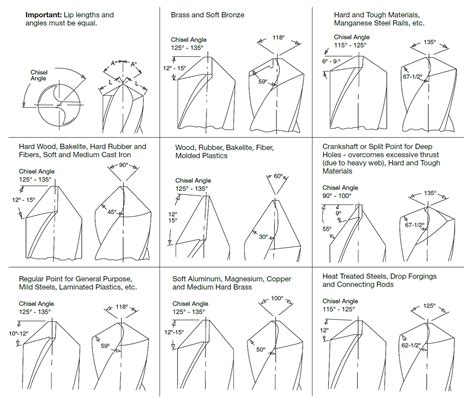

- Material being drilled: Different materials have varying hardness levels, which affect the optimal drill tip angle.

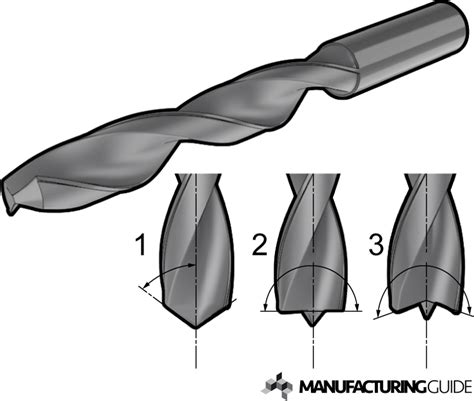

- Drill bit type: The type of drill bit used, such as a twist drill or a spade drill, affects the optimal tip angle.

- Drilling speed: The speed at which the drill bit rotates affects the optimal tip angle.

- Feed rate: The rate at which the drill bit is fed into the material affects the optimal tip angle.

7 Ways to Optimize Drill Tip Angle

Here are seven ways to optimize drill tip angle for the best results:

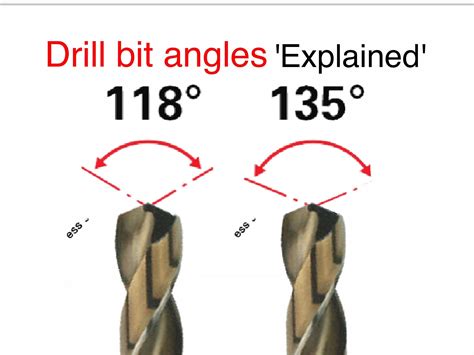

1. Choose the Right Drill Bit Type

The type of drill bit used can significantly impact the optimal drill tip angle. For example, a twist drill bit is best suited for drilling into softer materials, while a spade drill bit is better suited for drilling into harder materials.

- Twist drill bit: 118° to 135° tip angle

- Spade drill bit: 90° to 100° tip angle

2. Select the Optimal Drill Tip Angle Based on Material

The hardness of the material being drilled affects the optimal drill tip angle. For example, drilling into steel requires a sharper tip angle than drilling into aluminum.

- Steel: 130° to 140° tip angle

- Aluminum: 90° to 100° tip angle

- Wood: 60° to 80° tip angle

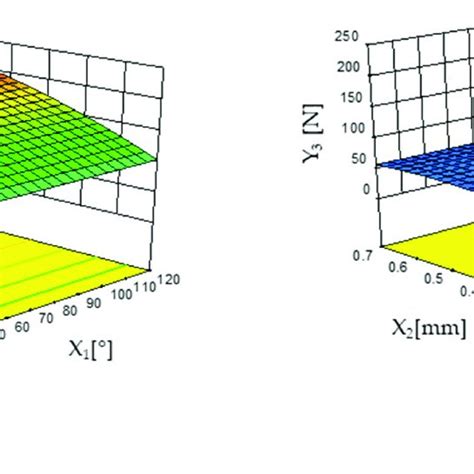

3. Adjust Drill Tip Angle Based on Drilling Speed

The drilling speed affects the optimal drill tip angle. Faster drilling speeds require a sharper tip angle, while slower drilling speeds require a duller tip angle.

- High-speed drilling: 120° to 130° tip angle

- Low-speed drilling: 90° to 100° tip angle

4. Consider the Feed Rate

The feed rate affects the optimal drill tip angle. A higher feed rate requires a sharper tip angle, while a lower feed rate requires a duller tip angle.

- High-feed rate drilling: 120° to 130° tip angle

- Low-feed rate drilling: 90° to 100° tip angle

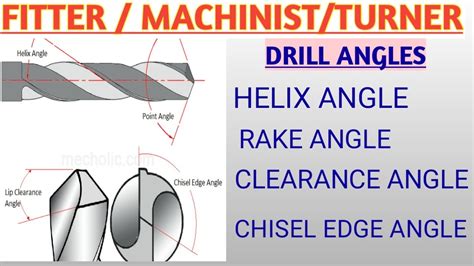

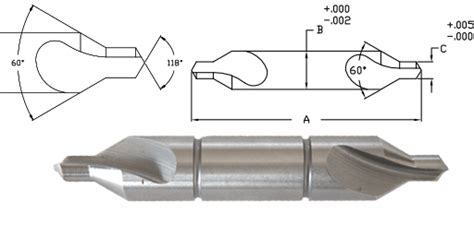

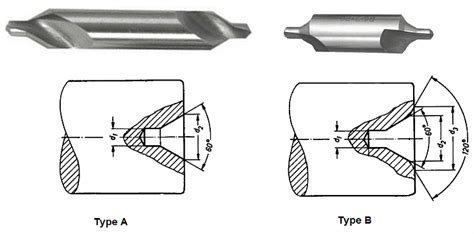

5. Use a Drill Bit with a Point Angle

A drill bit with a point angle can help optimize the drill tip angle. The point angle refers to the angle between the cutting edges of the drill bit.

- Point angle: 118° to 135°

6. Optimize Drill Tip Angle for Reduced Wear

A well-optimized drill tip angle can reduce wear on the drill bit. A sharper tip angle can reduce wear on the drill bit, but may also increase the risk of breakage.

- Reduced wear: 120° to 130° tip angle

7. Consider Using a Drill Bit with a Specialized Tip Angle

Some drill bits have specialized tip angles designed for specific drilling applications. For example, a drill bit with a 90° tip angle may be used for drilling into extremely hard materials.

- Specialized tip angle: 90° to 100°

📝 Note: The optimal drill tip angle may vary depending on the specific drilling application and material being drilled. It's essential to consult the manufacturer's recommendations and conduct experiments to determine the optimal drill tip angle for your specific use case.

What is the optimal drill tip angle for drilling into steel?

+

The optimal drill tip angle for drilling into steel is between 130° to 140°.

How does the feed rate affect the optimal drill tip angle?

+

A higher feed rate requires a sharper tip angle, while a lower feed rate requires a duller tip angle.

What is the point angle of a drill bit?

+

The point angle refers to the angle between the cutting edges of the drill bit, typically between 118° to 135°.

In conclusion, optimizing the drill tip angle is crucial for achieving efficient and effective drilling results. By considering the factors that affect drill tip angle, such as material, drill bit type, drilling speed, and feed rate, and using the seven methods outlined above, you can improve your drilling results and reduce wear on your drill bits.