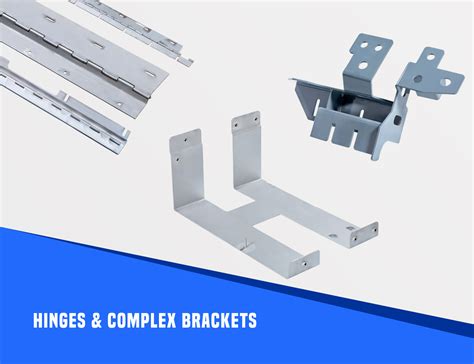

5 Essential Hinge and Bracket Installation Tips

Understanding Hinge and Bracket Installation: A Comprehensive Guide

Hinge and bracket installation is a crucial aspect of various construction and DIY projects. Whether you’re a seasoned professional or a novice, understanding the proper techniques and best practices for installing hinges and brackets can make all the difference in ensuring the stability, durability, and overall quality of your work. In this article, we’ll delve into the world of hinge and bracket installation, exploring five essential tips to help you achieve professional-grade results.

Tip #1: Choose the Right Hinge and Bracket for the Job

With the vast array of hinges and brackets available on the market, selecting the right ones for your project can be overwhelming. However, it’s crucial to choose hinges and brackets that are specifically designed for your particular application. Consider factors such as:

- Weight capacity: Ensure the hinges and brackets can support the weight of the door, shelf, or other components.

- Material: Select hinges and brackets made from materials that can withstand the environmental conditions of your project, such as rust-resistant or corrosion-proof options.

- Size: Choose hinges and brackets that fit your specific needs, taking into account the thickness of the materials and the desired level of adjustability.

🔧 Note: Always consult the manufacturer's specifications and recommendations when selecting hinges and brackets for your project.

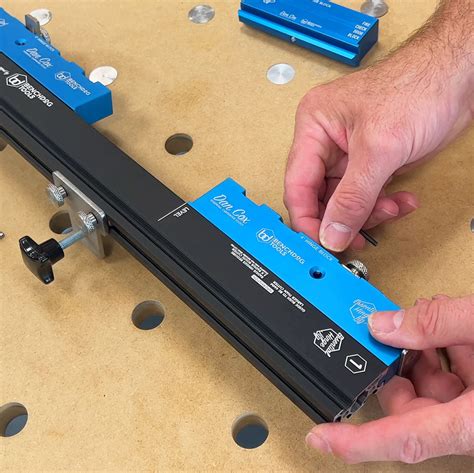

Tip #2: Measure Twice, Drill Once

Accurate measurement is critical when it comes to hinge and bracket installation. To ensure precise placement, follow these steps:

- Measure the location of the hinge or bracket on the door or shelf, taking into account any obstructions or irregularities.

- Transfer the measurements to the adjacent surface, using a level to ensure accuracy.

- Double-check your measurements before drilling or screwing the hinges or brackets into place.

By taking the time to measure carefully, you’ll avoid costly mistakes and ensure a smooth, stress-free installation process.

Tip #3: Use the Correct Drill Bits and Screws

Using the right drill bits and screws is vital for a secure and long-lasting hinge and bracket installation. Consider the following:

- Drill bits: Use high-quality drill bits that are specifically designed for the type of material you’re working with (e.g., wood, metal, or plastic).

- Screws: Select screws that match the material and weight capacity of the hinges and brackets. Avoid using screws that are too long or too short, as this can compromise the stability of the installation.

Tip #4: Consider the Alignment and Leveling

Proper alignment and leveling are essential for ensuring the smooth operation and longevity of your hinges and brackets. Follow these tips:

- Use a level to ensure the hinges and brackets are properly aligned, both horizontally and vertically.

- Adjust the hinges and brackets as needed to achieve a smooth, even motion.

- Double-check the alignment and leveling of the hinges and brackets after installation to prevent any issues down the line.

Tip #5: Test and Inspect the Installation

After completing the installation, it’s crucial to test and inspect the hinges and brackets to ensure they’re functioning properly. Check for:

- Smooth operation: Verify that the hinges and brackets move smoothly and effortlessly.

- Stability: Test the weight capacity of the hinges and brackets, ensuring they can support the intended load.

- Alignment: Double-check the alignment and leveling of the hinges and brackets to prevent any issues.

By following these five essential hinge and bracket installation tips, you’ll be well on your way to achieving professional-grade results that will stand the test of time.

In summary, by choosing the right hinges and brackets, measuring twice, using the correct drill bits and screws, considering alignment and leveling, and testing and inspecting the installation, you’ll be able to achieve a successful and stress-free hinge and bracket installation.

What type of hinges and brackets should I use for a heavy-duty door?

+

For heavy-duty doors, consider using hinges and brackets made from robust materials such as stainless steel or heavy-duty steel. Additionally, look for hinges and brackets with a high weight capacity and adjustable features to ensure a smooth operation.

How do I ensure proper alignment and leveling during hinge and bracket installation?

+

To ensure proper alignment and leveling, use a level and measure twice before drilling or screwing the hinges and brackets into place. Additionally, adjust the hinges and brackets as needed to achieve a smooth, even motion.

What type of drill bits and screws should I use for hinge and bracket installation?

+

Use high-quality drill bits and screws specifically designed for the type of material you’re working with (e.g., wood, metal, or plastic). Avoid using screws that are too long or too short, as this can compromise the stability of the installation.