M2 5 Screw: Essential Fastening Solution for Delicate Tasks

Understanding the M2 5 Screw: A Comprehensive Guide

When it comes to delicate tasks that require precision and accuracy, having the right tools and fastening solutions is crucial. Among the various types of screws available, the M2 5 screw stands out for its unique characteristics and applications. In this article, we will delve into the world of M2 5 screws, exploring their definition, uses, benefits, and more.

What is an M2 5 Screw?

An M2 5 screw is a type of metric screw that belongs to the M2 screw family. The “M2” designation refers to the screw’s diameter, which is 2 millimeters. The “5” in M2 5 screw indicates the screw’s length, which is 5 millimeters. This screw is part of the metric screw system, which is widely used in various industries, including electronics, aerospace, and automotive.

Applications of M2 5 Screws

M2 5 screws are designed for delicate tasks that require precision and accuracy. Some common applications of M2 5 screws include:

- Electronics: M2 5 screws are often used in electronic devices, such as smartphones, laptops, and tablets, to secure small components and assemblies.

- Aerospace: In the aerospace industry, M2 5 screws are used in aircraft and spacecraft to fasten lightweight components and assemblies.

- Automotive: M2 5 screws are used in the automotive industry to secure small components, such as sensors and actuators, in vehicles.

- Medical devices: M2 5 screws are used in medical devices, such as surgical instruments and implants, where precision and accuracy are critical.

Benefits of M2 5 Screws

M2 5 screws offer several benefits that make them an essential fastening solution for delicate tasks. Some of the benefits include:

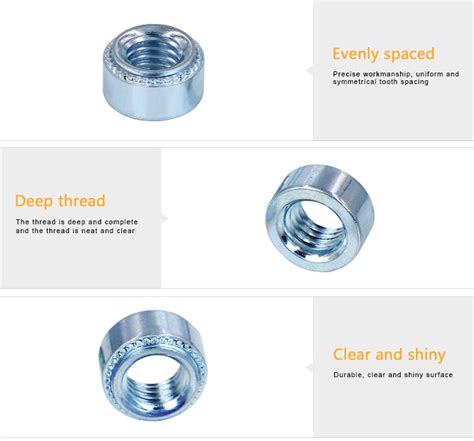

- Precision: M2 5 screws are designed for precision applications, offering a high degree of accuracy and reliability.

- Low profile: M2 5 screws have a low profile, making them ideal for use in compact and confined spaces.

- High strength: Despite their small size, M2 5 screws offer high strength and durability, making them suitable for use in demanding applications.

- Corrosion resistance: M2 5 screws are available in various materials, including stainless steel and titanium, which offer excellent corrosion resistance.

Choosing the Right M2 5 Screw

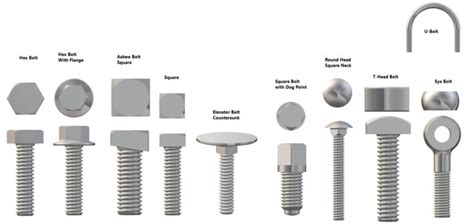

When selecting an M2 5 screw, it is essential to consider several factors, including:

- Material: M2 5 screws are available in various materials, including stainless steel, titanium, and brass. Choose a material that suits your application’s requirements.

- Coating: M2 5 screws can be coated with various materials, such as zinc, nickel, and chrome. Choose a coating that provides the required level of corrosion resistance and aesthetic appeal.

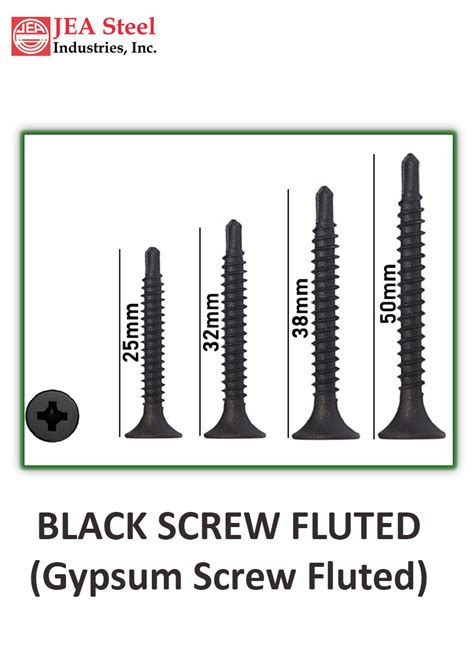

- Thread type: M2 5 screws are available with different thread types, including coarse and fine threads. Choose a thread type that suits your application’s requirements.

🔧 Note: Always consult the manufacturer's specifications and recommendations when selecting an M2 5 screw for your application.

Conclusion

In conclusion, M2 5 screws are an essential fastening solution for delicate tasks that require precision and accuracy. Their unique characteristics, benefits, and applications make them an ideal choice for various industries, including electronics, aerospace, and automotive. By understanding the definition, uses, and benefits of M2 5 screws, you can make informed decisions when selecting the right screw for your application.

What is the diameter of an M2 5 screw?

+

The diameter of an M2 5 screw is 2 millimeters.

What is the length of an M2 5 screw?

+

The length of an M2 5 screw is 5 millimeters.

What are the common applications of M2 5 screws?

+

M2 5 screws are commonly used in electronics, aerospace, automotive, and medical devices.