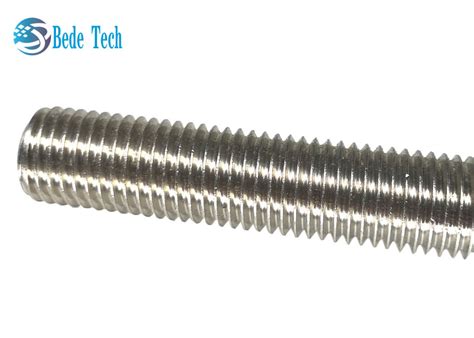

M4 Threaded Stud: The Essential Fastening Solution

What is an M4 Threaded Stud?

An M4 threaded stud is a type of fastening solution used to join two or more components together. It consists of a stud with a threaded end, typically made of metal, and is used in a wide range of applications, including industrial, automotive, and aerospace industries. The M4 designation refers to the metric thread size, which is 4 millimeters in diameter.

Key Features of M4 Threaded Studs

M4 threaded studs have several key features that make them an essential fastening solution:

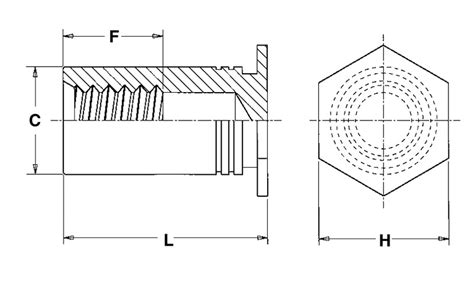

- Threaded End: The threaded end of the stud allows for easy attachment to other components, such as nuts, washers, and bearings.

- Metric Thread Size: The M4 designation refers to the metric thread size, which is 4 millimeters in diameter.

- High-Strength Material: M4 threaded studs are typically made of high-strength materials, such as steel or stainless steel, which provide excellent durability and resistance to corrosion.

- Variety of Lengths: M4 threaded studs are available in a range of lengths to accommodate different applications and requirements.

Applications of M4 Threaded Studs

M4 threaded studs are used in a wide range of applications, including:

- Industrial Automation: M4 threaded studs are used in industrial automation to connect components, such as actuators, sensors, and motors.

- Automotive Industry: M4 threaded studs are used in the automotive industry to connect components, such as engine mounts, suspension systems, and steering systems.

- Aerospace Industry: M4 threaded studs are used in the aerospace industry to connect components, such as aircraft engines, landing gear, and control systems.

- Medical Equipment: M4 threaded studs are used in medical equipment, such as MRI machines, X-ray machines, and surgical instruments.

Benefits of Using M4 Threaded Studs

M4 threaded studs offer several benefits, including:

- Easy Assembly: M4 threaded studs make it easy to assemble components, reducing the risk of errors and improving productivity.

- High-Strength Connection: M4 threaded studs provide a high-strength connection, ensuring that components remain securely attached even in high-stress applications.

- Corrosion Resistance: M4 threaded studs are made of corrosion-resistant materials, reducing the risk of corrosion and ensuring a long lifespan.

- Cost-Effective: M4 threaded studs are a cost-effective fastening solution, reducing the need for specialized tools and equipment.

How to Choose the Right M4 Threaded Stud

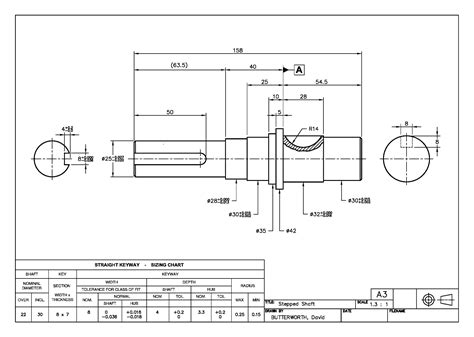

Choosing the right M4 threaded stud depends on several factors, including:

- Thread Size: Ensure that the thread size matches the requirements of the application.

- Length: Choose a stud with the correct length to accommodate the application.

- Material: Select a stud made of a material that meets the requirements of the application, such as corrosion resistance or high-strength.

- Finish: Consider the finish of the stud, such as zinc-plated or stainless steel, to ensure it meets the requirements of the application.

🔧 Note: When choosing an M4 threaded stud, ensure that it meets the requirements of the application, including thread size, length, material, and finish.

Installation and Safety Precautions

When installing an M4 threaded stud, ensure that:

- Follow proper installation procedures: Follow the manufacturer’s instructions for installation to ensure a secure and safe connection.

- Use proper tools: Use the correct tools, such as a wrench or socket, to avoid damaging the stud or surrounding components.

- Ensure proper torque: Apply the correct torque to avoid over-tightening or under-tightening the stud.

🚨 Note: Always follow proper installation procedures and safety precautions when installing an M4 threaded stud to ensure a secure and safe connection.

Conclusion

M4 threaded studs are an essential fastening solution used in a wide range of applications. With their high-strength material, threaded end, and variety of lengths, they provide a reliable and secure connection. When choosing an M4 threaded stud, ensure that it meets the requirements of the application, and follow proper installation procedures and safety precautions.

What is the thread size of an M4 threaded stud?

+

The thread size of an M4 threaded stud is 4 millimeters in diameter.

What are the benefits of using M4 threaded studs?

+

M4 threaded studs offer several benefits, including easy assembly, high-strength connection, corrosion resistance, and cost-effectiveness.

How do I choose the right M4 threaded stud?

+

Choose the right M4 threaded stud by considering factors such as thread size, length, material, and finish.