Accurate Measurements Made Easy with Calipers

Understanding the Importance of Accurate Measurements

In various industries such as engineering, manufacturing, and quality control, accurate measurements are crucial to ensure the quality and reliability of products. One of the most essential tools for making precise measurements is the caliper. Calipers are used to measure the distance between two points, the width of an object, or the depth of a hole. In this article, we will discuss the different types of calipers, their uses, and how to use them to make accurate measurements.

Types of Calipers

There are several types of calipers available, each designed for specific measurement tasks. Some of the most common types of calipers include:

- Digital Calipers: These calipers use a digital display to show the measurement readings. They are highly accurate and easy to use, making them a popular choice in many industries.

- Dial Calipers: These calipers use a dial indicator to show the measurement readings. They are less expensive than digital calipers but still offer high accuracy.

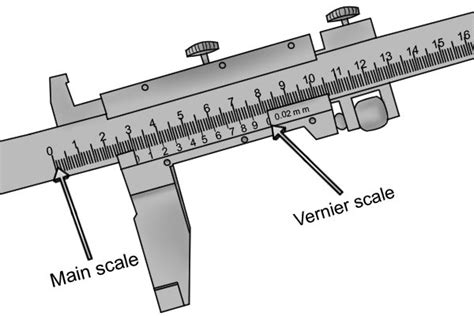

- Vernier Calipers: These calipers use a vernier scale to make precise measurements. They are commonly used in applications where high accuracy is required.

- Micrometer Calipers: These calipers use a micrometer screw to make precise measurements. They are commonly used in applications where very small measurements are required.

How to Use Calipers

Using calipers is relatively straightforward, but it does require some practice to get accurate measurements. Here are the basic steps to follow:

- Choose the right caliper: Select a caliper that is suitable for the measurement task. Consider the type of measurement, the size of the object, and the desired level of accuracy.

- Zero the caliper: Before taking a measurement, zero the caliper by closing the jaws and adjusting the dial or digital display to read zero.

- Place the object: Place the object to be measured between the caliper jaws, ensuring that the jaws are parallel to each other and perpendicular to the object.

- Take the measurement: Slowly close the caliper jaws until they touch the object. Take the measurement reading from the dial or digital display.

- Record the measurement: Record the measurement reading and repeat the process several times to ensure accuracy.

📝 Note: Always use a calibration certificate to verify the accuracy of your caliper. Regular calibration is essential to ensure accurate measurements.

Common Applications of Calipers

Calipers have a wide range of applications in various industries, including:

- Engineering: Calipers are used to measure the dimensions of parts, components, and assemblies.

- Manufacturing: Calipers are used to measure the dimensions of products during the manufacturing process.

- Quality Control: Calipers are used to inspect products and ensure that they meet quality standards.

- Research and Development: Calipers are used to measure the dimensions of prototypes and experimental models.

Tips for Accurate Measurements

To ensure accurate measurements with calipers, follow these tips:

- Use a stable surface: Always use a stable surface to take measurements, as any movement can affect the accuracy of the measurement.

- Use a calibration certificate: Regularly calibrate your caliper to ensure accuracy.

- Take multiple measurements: Take multiple measurements to ensure accuracy and reliability.

- Use the right jaws: Use the right jaws for the measurement task, as some jaws may be more suitable for certain types of measurements.

| Caliper Type | Accuracy | Measurement Range |

|---|---|---|

| Digital Caliper | ±0.01mm | 0-150mm |

| Dial Caliper | ±0.05mm | 0-200mm |

| Vernier Caliper | ±0.02mm | 0-300mm |

| Micrometer Caliper | ±0.001mm | 0-50mm |

In conclusion, accurate measurements are crucial in various industries, and calipers are an essential tool for making precise measurements. By choosing the right caliper, following the correct measurement procedure, and taking multiple measurements, you can ensure accurate and reliable results.

What is the most accurate type of caliper?

+

The most accurate type of caliper is the micrometer caliper, which can provide measurements with an accuracy of ±0.001mm.

How often should I calibrate my caliper?

+

It is recommended to calibrate your caliper regularly, ideally every 6-12 months, or as specified by the manufacturer.

Can I use a caliper to measure curved surfaces?

+

No, calipers are not designed to measure curved surfaces. For measuring curved surfaces, you may need to use a different type of measuring tool, such as a coordinate measuring machine (CMM) or a 3D scanner.