Metal Bending Tools for Precise Fabrication

Unlocking the Power of Metal Fabrication: Essential Tools for Precise Bending

Metal fabrication is a crucial process in various industries, including construction, automotive, and aerospace. One of the most critical aspects of metal fabrication is bending, which involves shaping metal into desired forms and angles. To achieve precise bending, metal fabricators rely on specialized tools that can handle various types of metals and bending requirements. In this article, we will explore the essential metal bending tools for precise fabrication, their applications, and tips for choosing the right tools for your projects.

Types of Metal Bending Tools

There are several types of metal bending tools, each designed for specific bending applications and metal types. Here are some of the most common metal bending tools:

- Manual Benders: These are hand-operated tools used for bending small to medium-sized metal pieces. Manual benders are ideal for low-volume production, prototyping, and repair work.

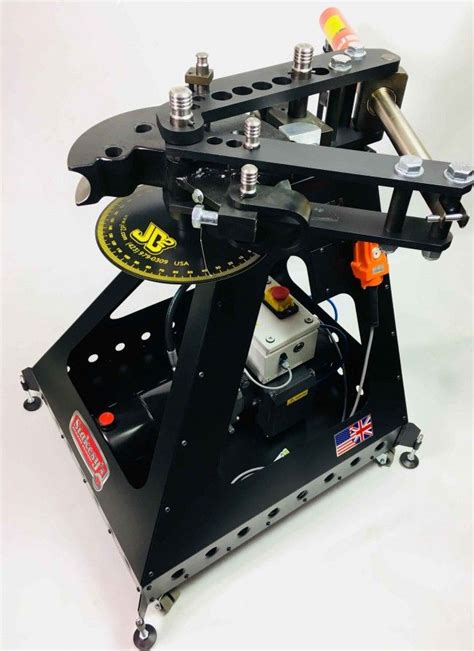

- Hydraulic Benders: These tools use hydraulic pressure to bend metal, offering more power and precision than manual benders. Hydraulic benders are suitable for medium to large-sized metal pieces and high-volume production.

- Pneumatic Benders: These tools use compressed air to bend metal, providing high speed and accuracy. Pneumatic benders are commonly used in high-volume production and are ideal for bending thin metals.

- Electric Benders: These tools use electric motors to bend metal, offering high precision and control. Electric benders are suitable for small to medium-sized metal pieces and are often used in precision fabrication applications.

Specialized Metal Bending Tools

In addition to the standard metal bending tools, there are specialized tools designed for specific bending applications:

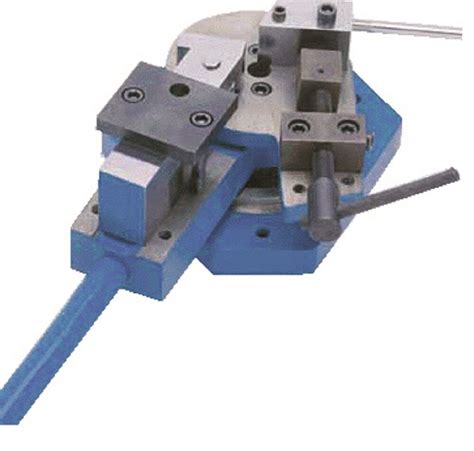

- Tube Benders: These tools are designed for bending metal tubes and pipes, commonly used in plumbing, HVAC, and automotive applications.

- Angle Benders: These tools are designed for bending metal angles and channels, often used in construction and structural fabrication.

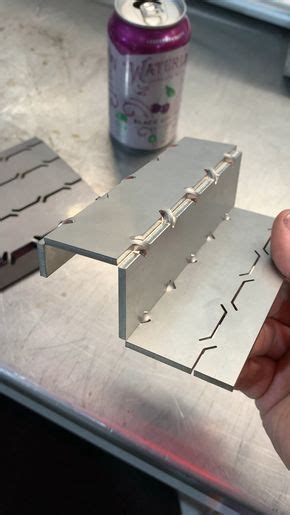

- Plate Benders: These tools are designed for bending metal plates and sheets, commonly used in shipbuilding, aerospace, and heavy equipment manufacturing.

- Section Benders: These tools are designed for bending metal sections, such as beams and girders, often used in construction and infrastructure projects.

Choosing the Right Metal Bending Tool

Selecting the right metal bending tool for your project depends on several factors, including:

- Metal type and thickness: Different metals and thicknesses require specific bending tools. For example, bending thick steel requires a more powerful tool than bending thin aluminum.

- Bending radius and angle: The bending radius and angle will determine the type of tool required. For example, a small bending radius requires a more precise tool, while a large bending angle requires a more powerful tool.

- Production volume: The production volume will determine the type of tool required. For example, high-volume production requires a more efficient and automated tool, while low-volume production can use a manual tool.

- Budget and space constraints: The budget and space constraints will determine the type of tool required. For example, a small workshop may require a more compact and affordable tool.

Tips for Precise Metal Bending

To achieve precise metal bending, follow these tips:

- Use the right tool for the job: Choose a tool that matches the metal type, thickness, and bending requirements.

- Set up the tool correctly: Ensure the tool is set up correctly, including the bending die and pressure settings.

- Use a mandrel or support: Use a mandrel or support to maintain the metal’s shape and prevent distortion.

- Monitor the bending process: Monitor the bending process to ensure accuracy and prevent errors.

- Use lubrication: Use lubrication to reduce friction and prevent metal damage.

🔩 Note: Always follow the manufacturer's instructions and safety guidelines when operating metal bending tools.

Conclusion

Metal bending is a critical process in various industries, and choosing the right tool is essential for precise fabrication. By understanding the types of metal bending tools, their applications, and tips for precise bending, metal fabricators can achieve high-quality results and improve their productivity.

What is the difference between manual and hydraulic benders?

+

Manual benders are hand-operated tools, while hydraulic benders use hydraulic pressure to bend metal. Hydraulic benders offer more power and precision than manual benders.

What is the purpose of a mandrel in metal bending?

+

A mandrel is used to maintain the metal’s shape and prevent distortion during the bending process.

What is the importance of lubrication in metal bending?

+

Lubrication reduces friction and prevents metal damage during the bending process.