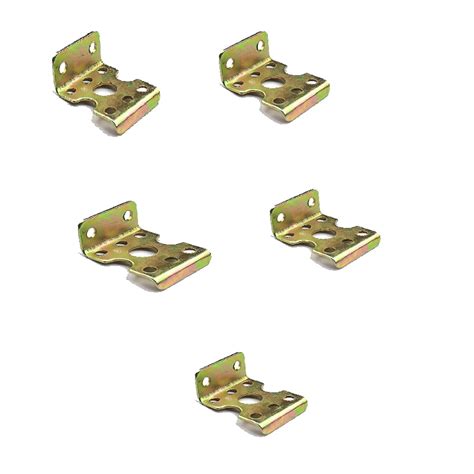

Motor Clamp Bracket: Secure Your Engine with Ease

Understanding the Importance of a Motor Clamp Bracket

A motor clamp bracket is a crucial component in securing your engine in place, providing a stable and reliable mounting system. It is designed to absorb vibrations, reduce noise, and prevent damage to the engine and surrounding components. The bracket acts as a shock absorber, dissipating the energy generated by the engine’s operation, thereby ensuring a smoother and quieter ride.

Benefits of Using a Motor Clamp Bracket

Using a motor clamp bracket offers several benefits, including:

- Improved Engine Stability: The bracket provides a secure mounting system, reducing the risk of engine movement or vibration.

- Reduced Noise: By absorbing vibrations, the bracket helps to minimize noise levels, creating a more comfortable driving experience.

- Increased Durability: The bracket helps to protect the engine and surrounding components from damage caused by excessive vibration.

- Easy Installation: Motor clamp brackets are designed for easy installation, making it a straightforward process to secure your engine.

Types of Motor Clamp Brackets

There are several types of motor clamp brackets available, each designed for specific applications:

- Standard Motor Clamp Brackets: These are the most common type, suitable for most engine applications.

- Heavy-Duty Motor Clamp Brackets: Designed for high-performance engines or heavy-duty applications.

- Adjustable Motor Clamp Brackets: Allow for adjustments to be made to accommodate different engine sizes or types.

Choosing the Right Motor Clamp Bracket

When selecting a motor clamp bracket, consider the following factors:

- Engine Size and Type: Ensure the bracket is compatible with your engine size and type.

- Material and Construction: Look for brackets made from high-quality materials, such as steel or aluminum.

- Load Capacity: Choose a bracket with a sufficient load capacity to handle the weight and stress of your engine.

- Adjustability: Consider a bracket with adjustable features to accommodate different engine sizes or types.

📝 Note: Always consult your engine manufacturer's recommendations when selecting a motor clamp bracket.

Installation and Maintenance

Installing a motor clamp bracket is a relatively straightforward process:

- Locate the Engine Mounting Points: Identify the engine’s mounting points and ensure the bracket is compatible.

- Mount the Bracket: Secure the bracket to the engine and surrounding components.

- Tighten the Fasteners: Tighten the fasteners in a star pattern to ensure even pressure.

Regular maintenance is essential to ensure the bracket continues to function correctly:

- Inspect the Bracket: Regularly inspect the bracket for signs of wear or damage.

- Tighten the Fasteners: Periodically tighten the fasteners to maintain even pressure.

- Replace the Bracket: Replace the bracket if signs of wear or damage are evident.

Common Applications

Motor clamp brackets are commonly used in various applications, including:

- Automotive: Cars, trucks, buses, and other vehicles.

- Industrial: Generators, pumps, and other industrial equipment.

- Marine: Boats, ships, and other marine vessels.

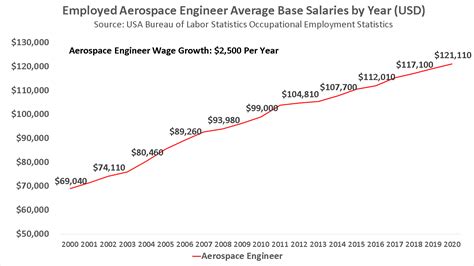

- Aerospace: Aircraft and other aerospace applications.

Conclusion

A motor clamp bracket is a vital component in securing your engine and ensuring a stable and reliable operation. By understanding the importance of a motor clamp bracket, choosing the right type, and following proper installation and maintenance procedures, you can ensure a smoother and quieter ride.

What is the purpose of a motor clamp bracket?

+

A motor clamp bracket is designed to secure the engine in place, providing a stable and reliable mounting system. It absorbs vibrations, reduces noise, and prevents damage to the engine and surrounding components.

What types of motor clamp brackets are available?

+

There are several types of motor clamp brackets available, including standard, heavy-duty, and adjustable brackets. Each type is designed for specific applications and engine types.

How do I choose the right motor clamp bracket for my engine?

+

When selecting a motor clamp bracket, consider factors such as engine size and type, material and construction, load capacity, and adjustability. Always consult your engine manufacturer’s recommendations.