Reduce 3D Printing Waste with P1S Initial Filament Purge

Reducing Waste in 3D Printing: A Guide to P1S Initial Filament Purge

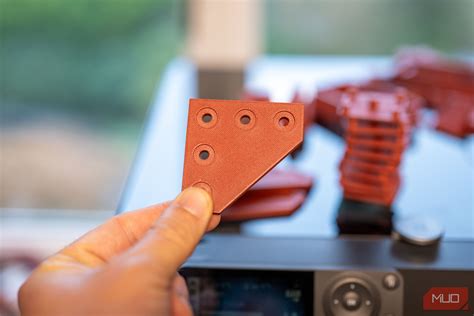

The world of 3D printing is rapidly evolving, with new technologies and techniques emerging every day. However, one of the significant challenges facing the industry is the amount of waste generated during the printing process. One effective way to reduce waste is by implementing the P1S initial filament purge. In this article, we will explore the concept of P1S, its benefits, and provide a step-by-step guide on how to implement it in your 3D printing workflow.

What is P1S Initial Filament Purge?

P1S stands for “Purge 1mm of Filament at the Start.” It is a simple yet effective technique that involves purging a small amount of filament at the beginning of each print job. This process helps to remove any debris, moisture, or contamination from the filament, resulting in a cleaner and more reliable printing process.

Benefits of P1S Initial Filament Purge

Implementing P1S initial filament purge can bring several benefits to your 3D printing workflow:

- Reduced waste: By purging a small amount of filament at the start, you can prevent printing failures caused by debris or contamination.

- Improved print quality: P1S helps to ensure that the filament is clean and free from defects, resulting in better print quality and reduced risk of printing errors.

- Increased efficiency: With P1S, you can reduce the number of failed prints and minimize the amount of time spent on re-printing.

- Cost savings: By reducing waste and improving print quality, you can save money on filament and energy costs.

Step-by-Step Guide to Implementing P1S

Implementing P1S initial filament purge is a straightforward process that can be done in a few simple steps:

- Configure your 3D printer: Make sure your 3D printer is configured to purge a small amount of filament at the start of each print job. This can usually be done through the printer’s settings menu or by editing the G-code.

- Set the purge amount: Set the purge amount to 1mm or less, depending on your printer’s specifications.

- Test the purge: Test the purge by printing a small object or a calibration test. Observe the purge process and ensure that the filament is being purged correctly.

- Monitor and adjust: Monitor the purge process and adjust the purge amount as needed.

Tips and Variations

Here are some additional tips and variations to help you optimize your P1S initial filament purge:

- Use a purge tower: Consider using a purge tower or a separate purge filament to separate the purge process from the main print job.

- Adjust the purge speed: Adjust the purge speed to optimize the process and prevent filament from oozing out during the purge.

- Use a different purge amount: Experiment with different purge amounts to find the optimal amount for your specific printer and filament.

📝 Note: Make sure to consult your 3D printer's manual and manufacturer's guidelines before implementing P1S initial filament purge.

Common Challenges and Solutions

Here are some common challenges and solutions related to implementing P1S initial filament purge:

| Challenge | Solution |

|---|---|

| Filament oozing out during purge | Adjust the purge speed or use a separate purge filament |

| Insufficient purge amount | Increase the purge amount or adjust the purge speed |

| Difficulty in monitoring the purge process | Use a camera or observation window to monitor the purge process |

| Challenge | Solution |

|---|---|

| Filament oozing out during purge | Adjust the purge speed or use a separate purge filament |

| Insufficient purge amount | Increase the purge amount or adjust the purge speed |

| Difficulty in monitoring the purge process | Use a camera or observation window to monitor the purge process |

Reducing Waste in 3D Printing

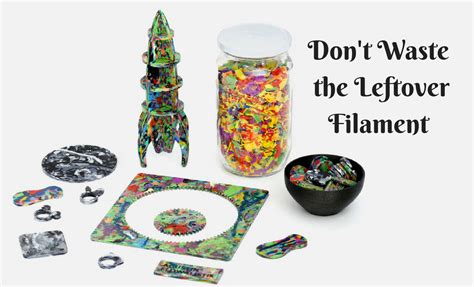

Implementing P1S initial filament purge is just one way to reduce waste in 3D printing. Here are some additional strategies to help minimize waste:

- Use eco-friendly filaments: Consider using eco-friendly filaments made from recycled materials or bioplastics.

- Optimize print settings: Optimize print settings to minimize material usage and reduce waste.

- Recycle filament: Recycle filament whenever possible or consider using a filament recycling service.

By implementing P1S initial filament purge and adopting these additional strategies, you can significantly reduce waste in your 3D printing workflow and contribute to a more sustainable future.

In summary, P1S initial filament purge is a simple yet effective technique that can help reduce waste, improve print quality, and increase efficiency in 3D printing. By following the steps outlined in this article and optimizing your purge process, you can take a significant step towards minimizing waste and promoting sustainability in the world of 3D printing.

Frequently Asked Questions

What is the optimal purge amount for P1S initial filament purge?

+

The optimal purge amount for P1S initial filament purge is typically 1mm or less, depending on your printer’s specifications.

Can I use P1S initial filament purge with any type of filament?

+

P1S initial filament purge can be used with most types of filament, but it’s recommended to consult your printer’s manual and manufacturer’s guidelines before implementing the technique.

How can I monitor the purge process during P1S initial filament purge?

+

You can monitor the purge process by using a camera or observation window to observe the purge tower or filament.