5 Ways to Choose the Right Pipe with Nozzle

Understanding the Importance of Choosing the Right Pipe with Nozzle

When it comes to various industrial applications, including irrigation, firefighting, and manufacturing, the right equipment can make all the difference in efficiency, safety, and productivity. One crucial element in many of these applications is the pipe with a nozzle. The nozzle is responsible for controlling the flow of liquids or gases, making it a critical component that can affect the performance of the entire system. However, with so many options available, choosing the right pipe with a nozzle can be a daunting task. Here are five key considerations to help you make an informed decision.

Evaluate Your Specific Needs and Requirements

Before selecting a pipe with a nozzle, it’s essential to have a clear understanding of your specific needs and requirements. This includes considering the type of fluid being handled (e.g., water, chemicals, or gases), the flow rate, pressure, and temperature. Additionally, think about the environment in which the pipe will be used (e.g., indoor, outdoor, exposure to extreme temperatures). These factors will help you narrow down your options and ensure you choose a pipe with a nozzle that can withstand the conditions it will be subjected to.

📝 Note: It's also important to consider any regulatory or industry standards that apply to your application, such as those related to safety, environmental protection, or quality control.

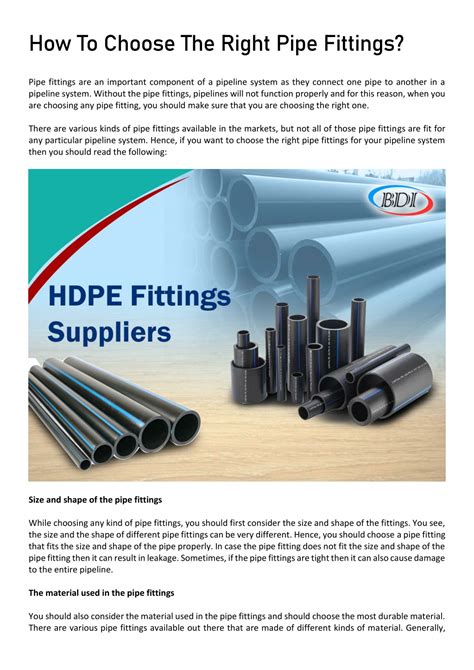

Consider the Material and Construction

The material and construction of the pipe and nozzle can significantly impact their performance and durability. Common materials used for pipes and nozzles include stainless steel, aluminum, PVC, and bronze. Each material has its own strengths and weaknesses, so it’s crucial to choose one that is compatible with your specific application.

- Stainless Steel: Known for its corrosion resistance and durability, stainless steel is an excellent choice for applications involving harsh chemicals or high pressures.

- Aluminum: Lightweight and corrosion-resistant, aluminum is often used in applications where weight is a concern, such as in aircraft or automotive industries.

- PVC: A cost-effective option, PVC is commonly used in applications involving water or other non-corrosive fluids.

- Bronze: An alloy of copper and tin, bronze is known for its strength, durability, and resistance to corrosion, making it an excellent choice for high-pressure applications.

Look at the Nozzle Design and Features

The design and features of the nozzle can significantly impact its performance and efficiency. Consider the following factors when evaluating nozzles:

- Flow Rate: Choose a nozzle that can handle the required flow rate for your application.

- Spray Pattern: Consider the type of spray pattern you need, such as a wide fan or a narrow jet.

- Pressure Drop: Look for nozzles with minimal pressure drop to ensure efficient operation.

- Clogging Resistance: If you’re handling fluids with suspended particles, look for nozzles with features that prevent clogging.

Check Compatibility with Other System Components

Ensure that the pipe with the nozzle is compatible with other components in your system, including pumps, valves, and fittings. Consider factors such as thread types, flange sizes, and material compatibility to avoid leaks, corrosion, or other issues.

Consult with Experts and Review Product Documentation

Finally, don’t hesitate to consult with experts or manufacturers’ representatives to get advice on choosing the right pipe with a nozzle for your specific application. Review product documentation, such as datasheets and manuals, to ensure you have a thorough understanding of the product’s features, benefits, and limitations.

By considering these five key factors, you can make an informed decision when choosing a pipe with a nozzle that meets your specific needs and requirements.

Today, choosing the right pipe with a nozzle can be a challenging task with various applications and products available in the market. Therefore, it is recommended to follow the guidelines as mentioned above to ensure you are buying the right product for your specific needs.

What is the most critical factor to consider when choosing a pipe with a nozzle?

+

The most critical factor is evaluating your specific needs and requirements, including the type of fluid, flow rate, pressure, and temperature.

What are the common materials used for pipes and nozzles?

+

Common materials include stainless steel, aluminum, PVC, and bronze, each with its strengths and weaknesses.

Why is it essential to check compatibility with other system components?

+

Ensuring compatibility prevents leaks, corrosion, or other issues that can affect system performance and safety.