7 Benefits of Plasma Transferred Arc Welding

Unlocking the Potential of Plasma Transferred Arc Welding

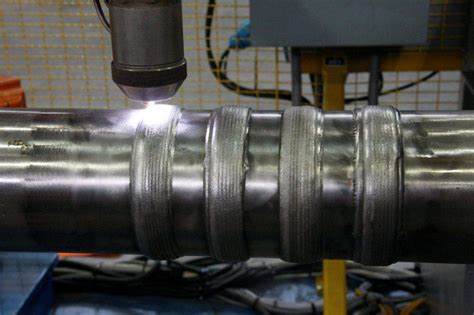

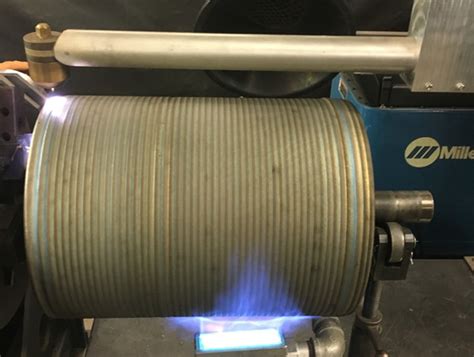

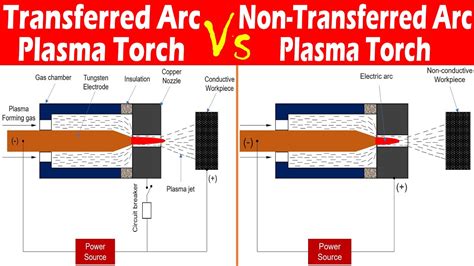

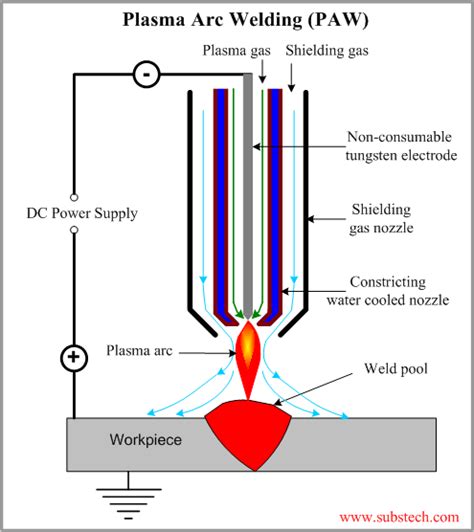

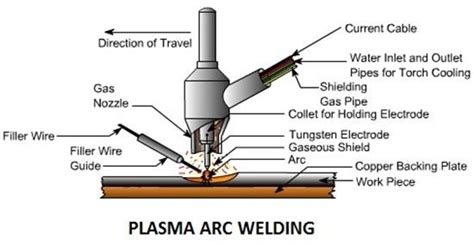

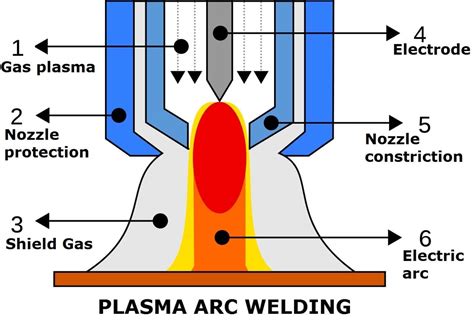

Plasma Transferred Arc (PTA) welding, also known as plasma welding, is a highly advanced welding process that has been gaining popularity in various industries due to its unique benefits. This process involves the use of a plasma arc to melt and join metals, resulting in high-quality welds with minimal distortion. In this article, we will delve into the 7 benefits of PTA welding and explore its applications in different sectors.

Benefit #1: High-Quality Welds

PTA welding produces high-quality welds with excellent mechanical properties, such as strength, ductility, and toughness. The plasma arc ensures a consistent and controlled heat input, resulting in a uniform weld pool and minimal porosity. This benefit is particularly important in industries where weld quality is critical, such as aerospace, automotive, and oil and gas.

Benefit #2: Low Distortion

One of the significant advantages of PTA welding is its ability to minimize distortion. The plasma arc allows for a precise control of heat input, which reduces the thermal stress and resulting distortion. This benefit is particularly useful in welding thin or delicate materials, where distortion can be a significant issue.

Benefit #3: High-Speed Welding

PTA welding can achieve high welding speeds, making it an ideal process for high-volume production. The plasma arc can maintain a consistent temperature and quality even at high speeds, resulting in increased productivity and reduced production time.

Benefit #4: Low Heat Input

The plasma arc in PTA welding allows for a low heat input, which reduces the thermal stress and resulting distortion. This benefit is particularly useful in welding materials with high thermal conductivity, such as aluminum and copper.

Benefit #5: Versatility

PTA welding is a versatile process that can be used on a wide range of materials, including steels, stainless steels, aluminum, copper, and titanium. The process can also be used for welding different joint configurations, such as butt joints, lap joints, and T-joints.

Benefit #6: Reduced Post-Weld Processing

PTA welding produces welds with minimal porosity and oxidation, reducing the need for post-weld processing. This benefit can save time and costs associated with cleaning, grinding, and machining the weld area.

Benefit #7: Environmental Benefits

PTA welding is an environmentally friendly process that produces minimal fumes and emissions. The process also reduces the need for shielding gases, which can contribute to greenhouse gas emissions.

Applications of PTA Welding

PTA welding has a wide range of applications in various industries, including:

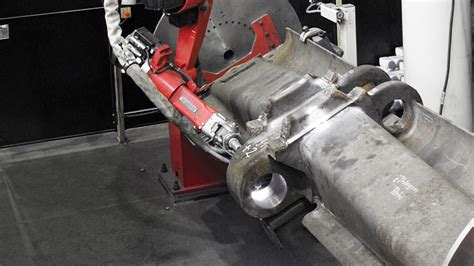

- Aerospace: PTA welding is used in the production of aircraft and spacecraft components, such as engine parts, heat exchangers, and fuel tanks.

- Automotive: PTA welding is used in the production of vehicle components, such as engine blocks, cylinder heads, and gearboxes.

- Oil and Gas: PTA welding is used in the production of pipelines, valves, and other equipment for the oil and gas industry.

- Power Generation: PTA welding is used in the production of power generation equipment, such as turbines, generators, and heat exchangers.

💡 Note: PTA welding requires specialized equipment and training. It is essential to ensure that the welding personnel have the necessary expertise and experience to produce high-quality welds.

In conclusion, PTA welding offers numerous benefits, including high-quality welds, low distortion, high-speed welding, low heat input, versatility, reduced post-weld processing, and environmental benefits. The process has a wide range of applications in various industries, and its advantages make it an attractive option for manufacturers seeking to improve their welding operations.

What is Plasma Transferred Arc Welding?

+

Plasma Transferred Arc (PTA) welding is a welding process that uses a plasma arc to melt and join metals.

What are the advantages of PTA welding?

+

PTA welding offers numerous benefits, including high-quality welds, low distortion, high-speed welding, low heat input, versatility, reduced post-weld processing, and environmental benefits.

What are the applications of PTA welding?

+

PTA welding has a wide range of applications in various industries, including aerospace, automotive, oil and gas, power generation, and more.