Unlocking Polyurethane's Potential: High Crosslink Density Explained

Unlocking Polyurethane's Potential: High Crosslink Density Explained

Polyurethane is a versatile polymer that has been widely used in various industries, including construction, automotive, and manufacturing. Its unique properties, such as high strength, durability, and resistance to chemicals and abrasion, make it an ideal material for a range of applications. However, polyurethane’s true potential can only be unlocked by understanding the concept of high crosslink density.

What is Crosslink Density?

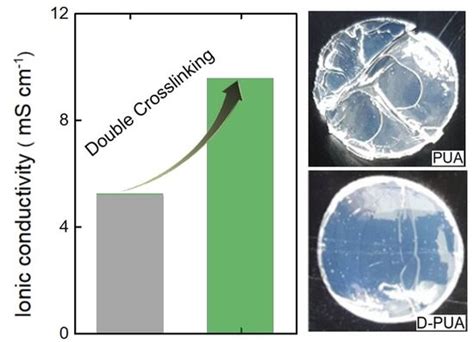

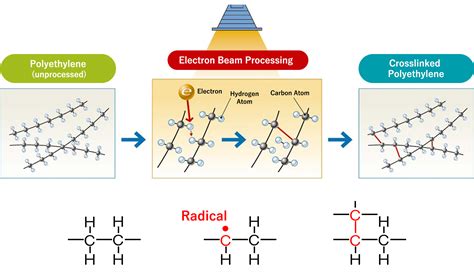

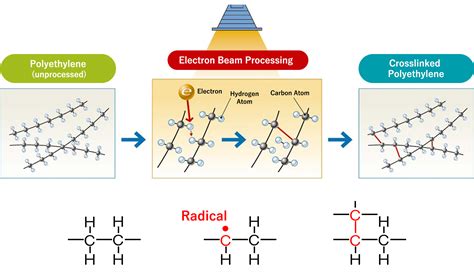

Crosslink density refers to the number of crosslinks between polymer chains in a given material. In polyurethane, crosslinks are formed through chemical reactions between the isocyanate and polyol components. These crosslinks create a three-dimensional network that gives polyurethane its strength, rigidity, and resistance to deformation.

Benefits of High Crosslink Density

High crosslink density polyurethane offers several benefits, including:

- Improved mechanical properties: High crosslink density polyurethane exhibits higher tensile strength, compressive strength, and modulus of elasticity compared to low crosslink density polyurethane.

- Increased chemical resistance: High crosslink density polyurethane is more resistant to chemicals, solvents, and fuels, making it an ideal material for applications in harsh environments.

- Enhanced abrasion resistance: High crosslink density polyurethane is more resistant to abrasion and wear, reducing the risk of material failure and extending its lifespan.

- Better thermal stability: High crosslink density polyurethane exhibits improved thermal stability, maintaining its mechanical properties over a wider range of temperatures.

How to Achieve High Crosslink Density

Achieving high crosslink density in polyurethane requires careful control of the formulation and manufacturing process. Some key factors that influence crosslink density include:

- Isocyanate index: The isocyanate index, which is the ratio of isocyanate to polyol, plays a critical role in determining crosslink density. A higher isocyanate index typically results in higher crosslink density.

- Polyol molecular weight: The molecular weight of the polyol can also impact crosslink density. Higher molecular weight polyols tend to produce higher crosslink density polyurethane.

- Catalyst selection: The choice of catalyst can also influence crosslink density. Some catalysts, such as tin-based catalysts, can promote higher crosslink density.

- Reaction conditions: Reaction conditions, such as temperature, pressure, and reaction time, can also impact crosslink density.

🔍 Note: Achieving high crosslink density requires careful optimization of the formulation and manufacturing process. It is recommended to work with experienced manufacturers or chemists to develop the optimal formulation.

Applications of High Crosslink Density Polyurethane

High crosslink density polyurethane has a wide range of applications, including:

- Coatings and paints: High crosslink density polyurethane is used in coatings and paints to provide improved durability and chemical resistance.

- Adhesives and sealants: High crosslink density polyurethane is used in adhesives and sealants to provide improved bonding strength and resistance to chemicals and abrasion.

- Foams and elastomers: High crosslink density polyurethane is used in foams and elastomers to provide improved mechanical properties and durability.

- Composites: High crosslink density polyurethane is used in composites to provide improved mechanical properties and resistance to chemicals and abrasion.

Conclusion

High crosslink density polyurethane offers a range of benefits, including improved mechanical properties, increased chemical resistance, and enhanced abrasion resistance. By understanding the factors that influence crosslink density and optimizing the formulation and manufacturing process, manufacturers can unlock polyurethane’s true potential. With its wide range of applications, high crosslink density polyurethane is poised to revolutionize industries and improve product performance.

What is the difference between high and low crosslink density polyurethane?

+

High crosslink density polyurethane has a higher number of crosslinks between polymer chains, resulting in improved mechanical properties, increased chemical resistance, and enhanced abrasion resistance. Low crosslink density polyurethane, on the other hand, has a lower number of crosslinks, resulting in lower mechanical properties and reduced chemical resistance.

How does high crosslink density polyurethane improve mechanical properties?

+

High crosslink density polyurethane improves mechanical properties by creating a three-dimensional network of crosslinks that provides additional strength and rigidity. This results in improved tensile strength, compressive strength, and modulus of elasticity.

What are the applications of high crosslink density polyurethane?

+

High crosslink density polyurethane has a wide range of applications, including coatings and paints, adhesives and sealants, foams and elastomers, and composites.