5 Tips for Perfect Prusa MK3 Z Calibration

Getting Started with Prusa MK3 Z Calibration

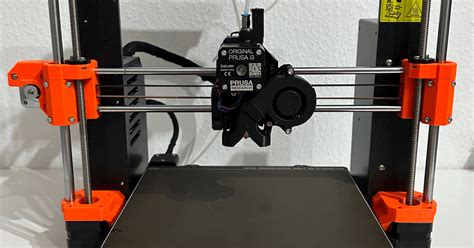

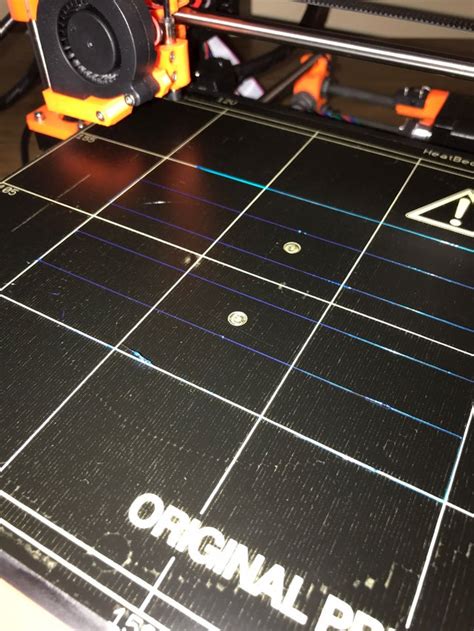

Calibrating the Z-axis of your Prusa MK3 3D printer is a crucial step to ensure accurate and high-quality prints. A well-calibrated Z-axis will result in smooth, consistent layers, and help prevent issues like Z-banding, layer shifting, and poor bed adhesion. In this article, we’ll walk you through the process of perfectly calibrating your Prusa MK3’s Z-axis.

Tip 1: Prepare Your Printer and Environment

Before starting the calibration process, make sure your printer is in a suitable environment. Ensure the room temperature is stable and away from direct sunlight, which can affect the printer’s performance. Also, verify that your printer is properly assembled, and all cables are securely connected.

🔧 Note: Ensure your printer's firmware is up-to-date, as newer versions often include improvements and bug fixes that can impact calibration.

Tip 2: Understand the Z-Calibration Process

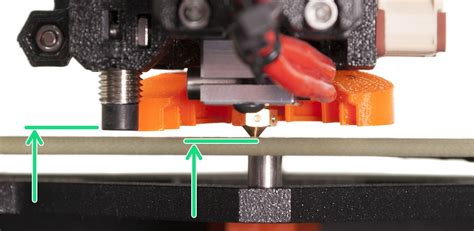

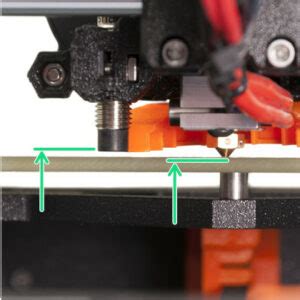

The Z-calibration process involves adjusting the Z-axis endstop, which determines the distance between the print bed and the nozzle. The goal is to find the optimal distance, known as the “Z-offset,” that allows for smooth and consistent layering. The Prusa MK3 uses a probe-based calibration system, which simplifies the process.

To start the calibration process:

- Navigate to the printer’s menu and select “Calibration” > “Z-Calibration.”

- Follow the on-screen instructions to begin the calibration process.

Tip 3: Use the Live Z-Adjust Feature

The Live Z-Adjust feature allows you to fine-tune the Z-axis during the calibration process. This feature is essential for achieving perfect calibration.

To access the Live Z-Adjust feature:

- During the calibration process, navigate to the “Live Z-Adjust” menu.

- Use the provided controls to adjust the Z-axis in small increments (typically 0.01-0.1 mm).

- Observe the nozzle’s distance from the print bed and adjust accordingly.

📊 Note: Keep track of the adjustments you make, as you'll need to input the final value into the printer's menu.

Tip 4: Verify the Z-Offset Value

After completing the calibration process, verify the Z-offset value to ensure it’s accurate.

To verify the Z-offset value:

- Measure the distance between the nozzle and the print bed using a caliper or other precision tool.

- Compare the measured value to the Z-offset value displayed in the printer’s menu.

- Make any necessary adjustments to the Z-offset value.

Tip 5: Fine-Tune and Repeat

Calibration is an iterative process, and it may take several attempts to achieve perfect results. Fine-tune the Z-axis by repeating the calibration process and making small adjustments as needed.

| Iteration | Z-Offset Value | Notes |

|---|---|---|

| 1 | 0.5 mm | Initial calibration attempt |

| 2 | 0.4 mm | Adjusted Z-offset value after measuring nozzle distance |

| 3 | 0.45 mm | Fine-tuned Z-offset value after repeat calibration |

By following these 5 tips, you’ll be able to achieve perfect Prusa MK3 Z calibration and enjoy high-quality prints with smooth, consistent layers.

As you’ve now learned, calibrating the Z-axis of your Prusa MK3 is a process that requires patience, attention to detail, and a willingness to iterate. By mastering this process, you’ll unlock the full potential of your 3D printer and take your printing capabilities to the next level.

What is the ideal Z-offset value for my Prusa MK3?

+

The ideal Z-offset value varies depending on your printer’s configuration, environment, and material usage. Typically, a Z-offset value between 0.4-0.6 mm is considered optimal.

How often should I recalibrate my Prusa MK3’s Z-axis?

+

Recalibrate your Prusa MK3’s Z-axis whenever you notice changes in print quality, after updating firmware, or when switching to a new type of filament.

What are the consequences of improper Z-calibration?

+

Improper Z-calibration can lead to issues like Z-banding, layer shifting, poor bed adhesion, and decreased print quality.