Optimizing the Solution Plasma Process for Enhanced Efficiency

Understanding the Solution Plasma Process

The Solution Plasma Process (SPP) is a revolutionary technology that has been gaining significant attention in recent years due to its potential to transform the way we approach various industrial and environmental applications. At its core, SPP is a process that utilizes plasma technology to treat and manipulate solutions, resulting in a wide range of benefits, including enhanced efficiency, reduced energy consumption, and improved environmental sustainability.

Key Components of the Solution Plasma Process

To optimize the SPP, it is essential to understand its key components and how they interact with each other. The primary components of SPP include:

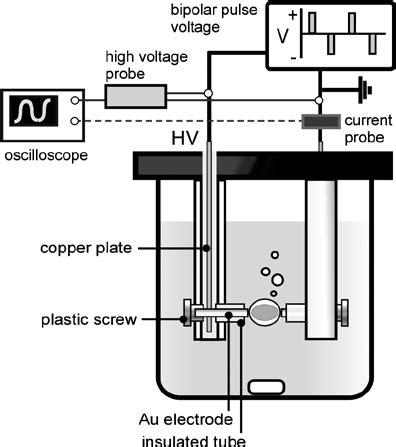

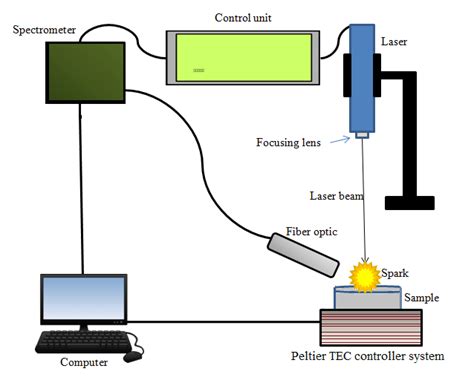

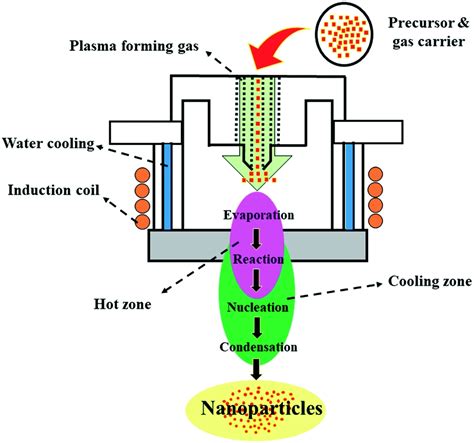

- Plasma Source: This is the heart of the SPP, responsible for generating the plasma that interacts with the solution. The plasma source can be in the form of electrical discharges, such as glow discharges or arc discharges.

- Solution: This is the liquid or gas that is being treated by the plasma. The solution can be a wide range of substances, including water, wastewater, organic compounds, and even gases.

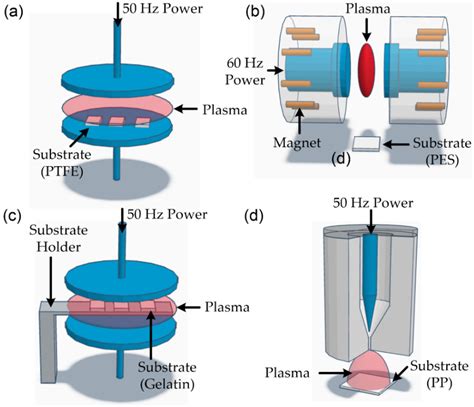

- Reactor: This is the chamber where the plasma and solution interact. The reactor design can vary depending on the specific application, but its primary function is to facilitate the interaction between the plasma and the solution.

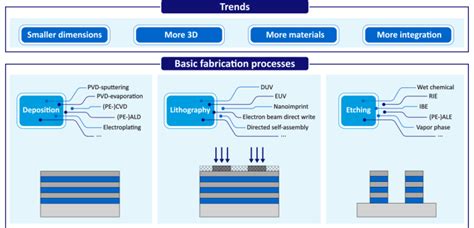

Optimization Techniques for Enhanced Efficiency

To optimize the SPP for enhanced efficiency, several techniques can be employed:

- Plasma Source Optimization: Adjusting the plasma source parameters, such as power input, frequency, and voltage, can significantly impact the efficiency of the SPP.

- Solution Optimization: The solution’s properties, such as pH, temperature, and composition, can be adjusted to enhance the interaction with the plasma.

- Reactor Design Optimization: The reactor design can be optimized to maximize the interaction between the plasma and the solution, resulting in improved efficiency.

- Operating Conditions Optimization: The operating conditions, such as pressure, temperature, and flow rate, can be optimized to enhance the efficiency of the SPP.

Benefits of Optimizing the Solution Plasma Process

Optimizing the SPP can result in a wide range of benefits, including:

- Improved Efficiency: Optimizing the SPP can result in improved efficiency, reducing energy consumption and increasing productivity.

- Enhanced Environmental Sustainability: The SPP can be optimized to reduce environmental impacts, such as reducing greenhouse gas emissions and minimizing waste generation.

- Increased Cost Savings: Optimizing the SPP can result in significant cost savings, reducing energy consumption and increasing productivity.

- Improved Product Quality: The SPP can be optimized to improve product quality, resulting in higher-quality outputs.

📝 Note: The SPP is a complex process, and optimization techniques may vary depending on the specific application. It is essential to consult with experts and conduct thorough research to determine the best optimization techniques for your specific use case.

Real-World Applications of the Solution Plasma Process

The SPP has a wide range of real-world applications, including:

- Water Treatment: The SPP can be used to treat wastewater, removing pollutants and contaminants, and producing clean water.

- Organic Synthesis: The SPP can be used to synthesize organic compounds, such as pharmaceuticals and fine chemicals.

- Environmental Remediation: The SPP can be used to remediate contaminated soil and groundwater, removing pollutants and contaminants.

- Food Processing: The SPP can be used to treat food products, such as meat and poultry, to improve food safety and quality.

Future Directions for the Solution Plasma Process

The SPP is a rapidly evolving field, with new applications and technologies emerging continuously. Future directions for the SPP include:

- Integration with Other Technologies: Integrating the SPP with other technologies, such as nanotechnology and biotechnology, can result in new and innovative applications.

- Scaling Up: Scaling up the SPP to industrial levels can result in significant cost savings and improved efficiency.

- New Applications: Exploring new applications for the SPP, such as in the field of energy storage and conversion, can result in new and innovative uses.

In summary, optimizing the Solution Plasma Process can result in significant benefits, including improved efficiency, enhanced environmental sustainability, increased cost savings, and improved product quality. By understanding the key components of the SPP and employing optimization techniques, we can unlock the full potential of this revolutionary technology.

What is the Solution Plasma Process?

+

The Solution Plasma Process (SPP) is a technology that utilizes plasma to treat and manipulate solutions, resulting in a wide range of benefits, including enhanced efficiency, reduced energy consumption, and improved environmental sustainability.

What are the key components of the Solution Plasma Process?

+

The key components of the SPP include the plasma source, solution, and reactor. The plasma source generates the plasma, the solution is the liquid or gas being treated, and the reactor is the chamber where the plasma and solution interact.

What are the benefits of optimizing the Solution Plasma Process?

+

Optimizing the SPP can result in improved efficiency, enhanced environmental sustainability, increased cost savings, and improved product quality.