Space Frame Chassis: The Future of Vehicle Design

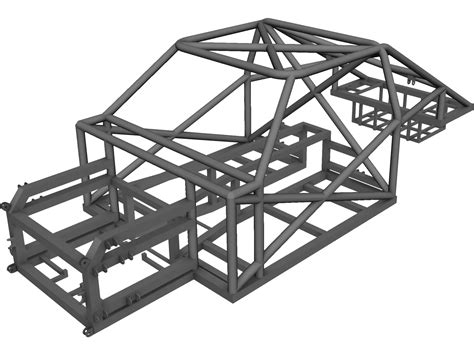

Introduction to Space Frame Chassis

The automotive industry is constantly evolving, and one of the most significant advancements in recent years is the development of space frame chassis. Also known as spaceframe or lattice frame, this design concept has revolutionized the way vehicles are built, offering unparalleled strength, safety, and efficiency. In this article, we will delve into the world of space frame chassis, exploring its history, benefits, and applications in the automotive industry.

History of Space Frame Chassis

The concept of space frame chassis dates back to the early 20th century, when aircraft manufacturers began using lattice structures to build lightweight yet strong frames for their planes. This design approach was later adopted by the automotive industry, particularly in the 1960s and 1970s, when sports car manufacturers like Ferrari and Lamborghini started using space frames to create high-performance vehicles.

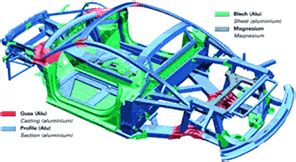

However, it wasn’t until the 1990s that space frame chassis gained widespread acceptance in the automotive industry. The introduction of advanced materials like aluminum and carbon fiber, combined with improved manufacturing techniques, made it possible to produce space frames that were both strong and affordable.

Benefits of Space Frame Chassis

So, what makes space frame chassis so special? Here are some of the key benefits:

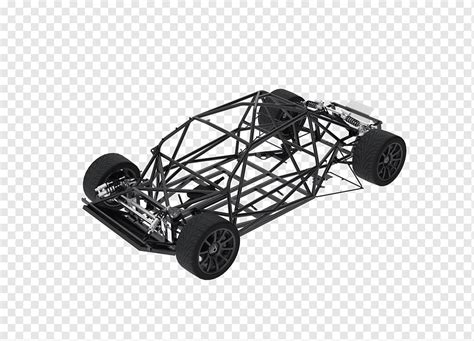

- Improved strength-to-weight ratio: Space frames are designed to provide exceptional strength while minimizing weight. This is achieved through the use of optimized structures, advanced materials, and clever design.

- Enhanced safety: Space frames are designed to absorb and distribute crash forces, reducing the risk of injury to occupants. This is particularly important in high-performance vehicles, where safety is paramount.

- Increased efficiency: By reducing weight and improving structural efficiency, space frames can help improve fuel efficiency, reduce emissions, and enhance overall vehicle performance.

- Reduced production costs: Space frames can be manufactured using a variety of techniques, including casting, forging, and welding. This flexibility can help reduce production costs and improve manufacturing efficiency.

Applications of Space Frame Chassis

Space frame chassis are used in a wide range of vehicles, from high-performance sports cars to family sedans and SUVs. Here are some examples of vehicles that feature space frame chassis:

- Ferrari 488 GTB: This Italian supercar features a advanced space frame chassis made from aluminum and carbon fiber.

- Lamborghini Huracan: The Huracan’s space frame chassis is designed to provide exceptional strength, safety, and handling.

- Audi R8: The R8’s space frame chassis is made from aluminum and features a unique modular design.

- Tesla Model S: The Model S features a advanced space frame chassis made from aluminum and steel.

Design and Manufacturing Process

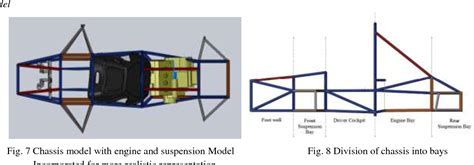

The design and manufacturing process for space frame chassis involves several key steps:

- Computer-aided design (CAD): Designers use CAD software to create a digital model of the space frame chassis.

- Finite element analysis (FEA): The digital model is then subjected to FEA, which simulates various loads and stresses to optimize the design.

- Prototyping: A prototype of the space frame chassis is created using a variety of techniques, including casting, forging, and welding.

- Testing: The prototype is then tested to validate its strength, safety, and performance.

🚨 Note: The design and manufacturing process for space frame chassis can be complex and time-consuming, requiring significant expertise and resources.

Challenges and Limitations

While space frame chassis offer many benefits, there are also some challenges and limitations to consider:

- High production costs: Space frames can be expensive to produce, particularly when using advanced materials like carbon fiber.

- Complex design and manufacturing process: The design and manufacturing process for space frame chassis can be complex and time-consuming.

- Limited repairability: Space frames can be difficult to repair, particularly if damaged in a crash.

Future of Space Frame Chassis

The future of space frame chassis looks bright, with ongoing advancements in materials, design, and manufacturing. Here are some trends to watch:

- Increased use of advanced materials: Expect to see more widespread use of advanced materials like carbon fiber, aluminum, and steel.

- Improved design and manufacturing techniques: Advances in CAD, FEA, and prototyping will continue to improve the design and manufacturing process for space frame chassis.

- Electric and hybrid vehicles: Space frame chassis will play a key role in the development of electric and hybrid vehicles, where weight reduction and efficiency are paramount.

What is a space frame chassis?

+

A space frame chassis is a type of vehicle frame that uses a lattice structure to provide exceptional strength, safety, and efficiency.

What are the benefits of space frame chassis?

+

The benefits of space frame chassis include improved strength-to-weight ratio, enhanced safety, increased efficiency, and reduced production costs.

What types of vehicles use space frame chassis?

+

Space frame chassis are used in a wide range of vehicles, including high-performance sports cars, family sedans, and SUVs.

In conclusion, space frame chassis have revolutionized the automotive industry, offering unparalleled strength, safety, and efficiency. With ongoing advancements in materials, design, and manufacturing, the future of space frame chassis looks bright. Whether you’re a car enthusiast, engineer, or manufacturer, understanding the benefits and applications of space frame chassis is essential for anyone interested in the automotive industry.