7 Ways Stereolithography 3D Printers Revolutionize Manufacturing

Revolutionizing Manufacturing with Stereolithography 3D Printers

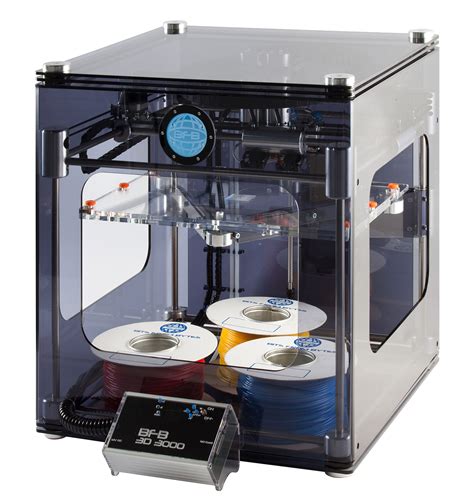

The advent of Stereolithography (SLA) 3D printing has transformed the manufacturing landscape, offering unparalleled precision, speed, and cost-effectiveness. This innovative technology has revolutionized the way products are designed, prototyped, and produced, enabling businesses to stay ahead of the competition. In this article, we will explore the 7 ways SLA 3D printers are transforming manufacturing.

1. Rapid Prototyping and Reduced Lead Times

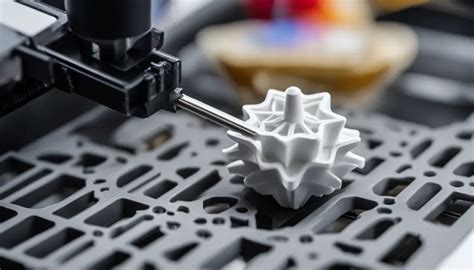

SLA 3D printing enables rapid prototyping, allowing manufacturers to quickly test and refine their designs. This significantly reduces lead times, as traditional prototyping methods can take weeks or even months. With SLA, manufacturers can produce multiple iterations of a design in a matter of hours, accelerating the product development process.

💡 Note: SLA's rapid prototyping capabilities enable manufacturers to respond quickly to changing market demands and customer needs.

2. Increased Complexity and Customization

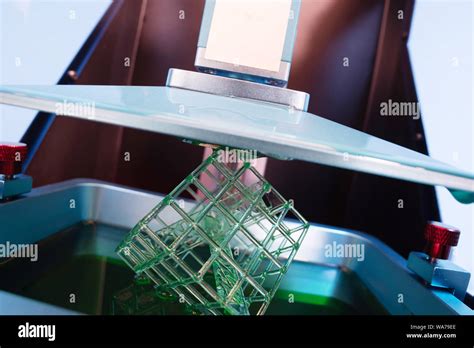

SLA 3D printing allows for the creation of complex geometries and customized products with ease. This technology enables manufacturers to produce intricate designs, such as lattice structures, hollow cavities, and internal channels, which were previously impossible to achieve with traditional manufacturing methods.

3. Enhanced Product Quality and Accuracy

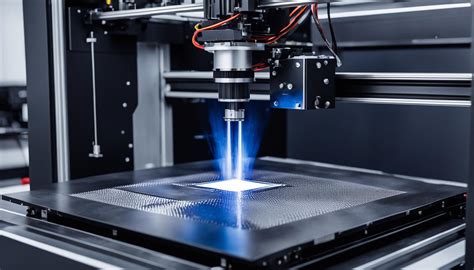

SLA 3D printing produces parts with exceptional accuracy and surface finish. This technology uses a laser to solidify liquid resin, resulting in parts with smooth surfaces, precise details, and minimal post-processing requirements. The high level of accuracy and quality enables manufacturers to produce end-use products, rather than just prototypes.

4. Reduced Material Waste and Environmental Impact

SLA 3D printing is an additive manufacturing process, which means that material is added layer by layer, reducing waste and minimizing environmental impact. This technology also enables the use of sustainable materials, such as plant-based resins, which further reduces the environmental footprint of manufacturing.

🌎 Note: SLA's additive process reduces material waste, conserves resources, and promotes sustainability in manufacturing.

5. Cost-Effective Production and Reduced Tooling Costs

SLA 3D printing eliminates the need for traditional tooling, such as molds and dies, which can be costly and time-consuming to produce. This technology also enables on-demand production, reducing inventory costs and minimizing waste. The cost-effectiveness of SLA makes it an attractive option for low- to medium-volume production runs.

6. Improved Product Performance and Functionality

SLA 3D printing enables the creation of products with complex internal structures, which can improve their performance and functionality. For example, lattice structures can be used to create lightweight yet strong parts, while internal channels can be used to create complex fluid dynamics systems.

7. Enhanced Collaboration and Design Freedom

SLA 3D printing enables designers and engineers to collaborate more effectively, as they can quickly test and refine their designs. This technology also provides design freedom, allowing manufacturers to produce complex geometries and customized products that were previously impossible to achieve.

| Traditional Manufacturing | Stereolithography 3D Printing |

|---|---|

| Long lead times | Rapid prototyping and reduced lead times |

| Limited complexity and customization | Increased complexity and customization |

| Higher material waste and environmental impact | Reduced material waste and environmental impact |

In conclusion, Stereolithography 3D printing has revolutionized manufacturing by enabling rapid prototyping, increasing complexity and customization, and reducing material waste and environmental impact. This technology has also improved product quality and accuracy, reduced tooling costs, and enhanced collaboration and design freedom. As the manufacturing landscape continues to evolve, SLA 3D printing is poised to play a significant role in shaping the future of production.

What is Stereolithography 3D printing?

+

Stereolithography (SLA) 3D printing is a technology that uses a laser to solidify liquid resin, creating highly accurate and detailed parts.

What are the benefits of using SLA 3D printing in manufacturing?

+

SLA 3D printing offers numerous benefits, including rapid prototyping, increased complexity and customization, reduced material waste and environmental impact, and improved product quality and accuracy.

What types of products can be produced using SLA 3D printing?

+

SLA 3D printing can produce a wide range of products, including prototypes, end-use parts, and production components, with applications in industries such as aerospace, automotive, and healthcare.