5 Tips for Orca Slicer Top Line Calibration

Understanding the Importance of Orca Slicer Top Line Calibration

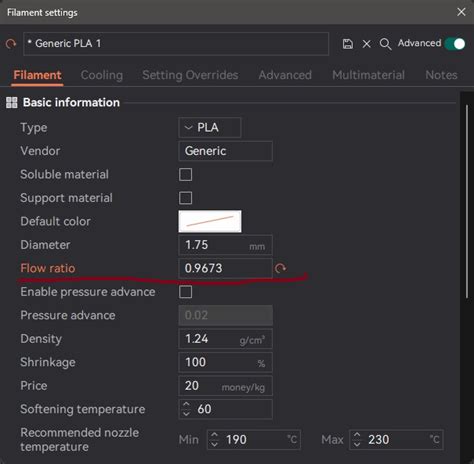

For individuals who work with 3D printing, the Orca Slicer is a popular tool for slicing models into printable layers. One crucial aspect of using the Orca Slicer is ensuring that the top line calibration is accurate. A well-calibrated top line ensures that the first layer of the print adheres properly to the build plate, which is essential for a successful print. In this article, we will explore five tips for calibrating the Orca Slicer’s top line.

Tip 1: Understand the Basics of Top Line Calibration

Before diving into the calibration process, it’s essential to understand the basics of top line calibration. The top line calibration is responsible for setting the initial layer height and ensuring that the first layer adheres properly to the build plate. The calibration process involves adjusting the Z-axis offset to find the optimal distance between the nozzle and the build plate.

📝 Note: It's crucial to follow the manufacturer's guidelines for top line calibration, as different printers may have varying requirements.

Tip 2: Prepare Your Printer and Environment

Before starting the calibration process, ensure that your printer and environment are prepared. This includes:

- Ensuring the build plate is clean and free of debris

- Preheating the printer to the recommended temperature

- Setting the Z-axis offset to the default value (usually 0)

- Ensuring the printer is in a stable and level environment

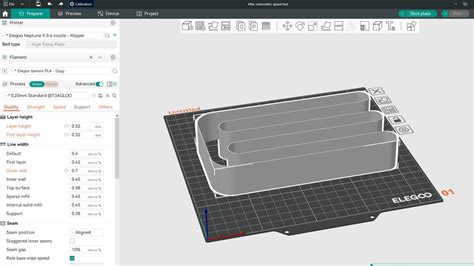

Tip 3: Perform the Calibration Process

The calibration process involves adjusting the Z-axis offset to find the optimal distance between the nozzle and the build plate. Here’s a step-by-step guide:

- Start by setting the Z-axis offset to a negative value (e.g., -0.1 mm)

- Print a calibration test model (usually a single layer rectangle)

- Observe the first layer and adjust the Z-axis offset accordingly

- If the first layer is too high, decrease the Z-axis offset

- If the first layer is too low, increase the Z-axis offset

- Repeat steps 2-3 until the first layer is properly adhered to the build plate

| Z-axis Offset | First Layer Adhesion |

|---|---|

| -0.1 mm | Too high |

| -0.05 mm | Optimal |

| -0.01 mm | Too low |

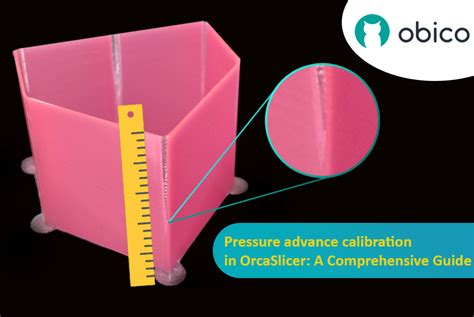

Tip 4: Refine the Calibration

Once you’ve found the optimal Z-axis offset, refine the calibration by:

- Printing multiple calibration test models to ensure consistency

- Adjusting the Z-axis offset in small increments (e.g., 0.01 mm) to fine-tune the calibration

- Verifying the calibration by printing a complex model

Tip 5: Save and Verify the Calibration

After completing the calibration process, save the Z-axis offset value and verify the calibration by:

- Saving the Z-axis offset value in the Orca Slicer software

- Printing a complex model to ensure the calibration is accurate

- Periodically re-calibrating the top line to ensure optimal performance

By following these five tips, you’ll be able to accurately calibrate the Orca Slicer’s top line and ensure successful prints.

In summary, calibrating the Orca Slicer’s top line is crucial for successful 3D printing. By understanding the basics, preparing your printer and environment, performing the calibration process, refining the calibration, and saving and verifying the calibration, you’ll be able to achieve optimal results.

What is the purpose of top line calibration in the Orca Slicer?

+

The purpose of top line calibration is to set the initial layer height and ensure that the first layer adheres properly to the build plate.

How often should I re-calibrate the top line?

+

It’s recommended to re-calibrate the top line periodically to ensure optimal performance. The frequency of re-calibration depends on the usage and environment of the printer.

What are the consequences of incorrect top line calibration?

+

Incorrect top line calibration can result in poor adhesion, warping, and failed prints.