3D Print Your Trijicon SRO Tool Today

Introduction to 3D Printing Your Trijicon SRO Tool

The Trijicon Specialized Reflex Optic (SRO) is a popular reflex sight used by firearms enthusiasts and professionals alike. One of the essential tools for maintaining and operating the SRO is the Trijicon SRO tool. However, this tool can be difficult to find and purchase, leading many users to explore alternative solutions. One innovative approach is to 3D print your own Trijicon SRO tool. In this article, we will guide you through the process of creating your own 3D printed Trijicon SRO tool.

What You Need to Get Started

Before you begin, make sure you have the following:

- A 3D printer (FDM or SLA)

- 3D modeling software (e.g., Tinkercad, Fusion 360)

- Trijicon SRO tool design files (available online or created from scratch)

- 3D printing materials (e.g., PLA, ABS, PETG)

- Post-processing tools (e.g., sandpaper, files)

🔧 Note: If you're new to 3D printing, it's essential to familiarize yourself with the basics of 3D modeling and printing before attempting to create your own Trijicon SRO tool.

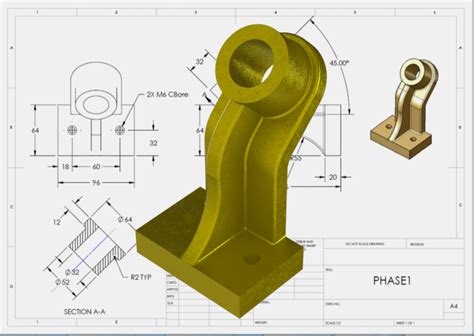

Designing Your Trijicon SRO Tool

To create your own Trijicon SRO tool, you’ll need to design the model using 3D modeling software. You can either find pre-existing designs online or create your own from scratch. Here are some tips to keep in mind:

- Use reference images of the original Trijicon SRO tool to ensure accuracy

- Measure the dimensions of the tool and incorporate them into your design

- Consider adding features such as a handle or ergonomic grip

- Use a suitable material thickness to ensure durability

| Design Parameter | Value |

|---|---|

| Material Thickness | 2-3 mm |

| Handle Length | 5-7 cm |

| Grip Diameter | 1-2 cm |

3D Printing Your Trijicon SRO Tool

Once you have your design ready, it’s time to 3D print your Trijicon SRO tool. Here are some tips to keep in mind:

- Choose a suitable 3D printing material (e.g., PLA, ABS, PETG)

- Adjust your 3D printer settings for optimal print quality

- Use a brim or raft to prevent warping and ensure adhesion

- Monitor the print job and adjust settings as needed

🔧 Note: Make sure to follow safety guidelines when working with 3D printers, including wearing protective gear and ensuring proper ventilation.

Post-Processing Your Trijicon SRO Tool

After the print job is complete, you’ll need to post-process your Trijicon SRO tool. Here are some steps to follow:

- Remove any support material or raft

- Sand the tool to smooth out any rough edges or surfaces

- Apply a finish (e.g., paint, varnish) to protect the material and enhance appearance

Using Your 3D Printed Trijicon SRO Tool

Once your Trijicon SRO tool is complete, you can use it to maintain and operate your SRO reflex sight. Here are some tips to keep in mind:

- Familiarize yourself with the tool’s functions and features

- Use the tool to adjust and maintain your SRO reflex sight

- Store the tool in a safe and secure location when not in use

In summary, 3D printing your own Trijicon SRO tool is a cost-effective and innovative solution for maintaining and operating your SRO reflex sight. By following the steps outlined in this article, you can create your own custom tool and enjoy the benefits of 3D printing.

What is the Trijicon SRO tool used for?

+

The Trijicon SRO tool is used to maintain and operate the Trijicon Specialized Reflex Optic (SRO) reflex sight.

What materials can I use to 3D print my Trijicon SRO tool?

+

You can use a variety of 3D printing materials, including PLA, ABS, and PETG.

How do I post-process my 3D printed Trijicon SRO tool?

+

You can post-process your Trijicon SRO tool by removing support material, sanding, and applying a finish.