6 Axis Robot Model: Boosting Industrial Efficiency

Revolutionizing Industrial Automation with 6 Axis Robot Model

The industrial landscape is undergoing a significant transformation with the integration of advanced robotics. Among the various robotic models, the 6 axis robot model has emerged as a game-changer, offering unparalleled flexibility and precision. In this article, we will delve into the features, applications, and benefits of the 6 axis robot model, highlighting its potential to boost industrial efficiency.

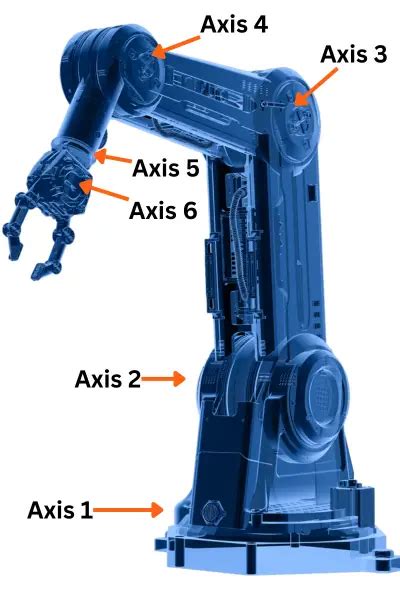

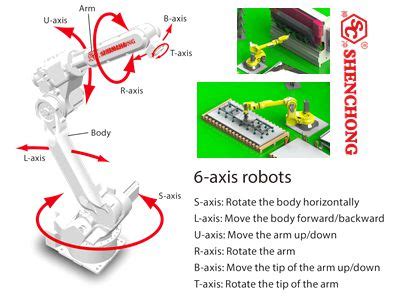

Understanding the 6 Axis Robot Model

The 6 axis robot model is a type of articulated robot designed to perform a wide range of tasks with precision and accuracy. It features six joints, each providing a degree of freedom, allowing the robot to move its end effector in a 3D space. This robotic model is commonly used in industries such as manufacturing, logistics, and healthcare, where tasks require flexibility and adaptability.

Key Features of the 6 Axis Robot Model

Some of the key features of the 6 axis robot model include:

- High precision and accuracy: The 6 axis robot model is capable of achieving high precision and accuracy, making it ideal for tasks that require intricate movements.

- Flexibility and adaptability: The six joints provide a high degree of flexibility, allowing the robot to perform a wide range of tasks, from simple pick-and-place operations to complex assembly tasks.

- High speed and repeatability: The 6 axis robot model is designed to operate at high speeds, making it suitable for high-volume production environments.

- Compact design: Despite its capabilities, the 6 axis robot model has a compact design, making it suitable for installation in confined spaces.

Applications of the 6 Axis Robot Model

The 6 axis robot model has a wide range of applications across various industries, including:

- Manufacturing: The 6 axis robot model is widely used in manufacturing for tasks such as assembly, welding, and material handling.

- Logistics: The robot is used in logistics for tasks such as packaging, palletizing, and depalletizing.

- Healthcare: The 6 axis robot model is used in healthcare for tasks such as lab testing, patient care, and surgical procedures.

- Food processing: The robot is used in food processing for tasks such as packaging, inspection, and sorting.

Benefits of the 6 Axis Robot Model

The 6 axis robot model offers numerous benefits, including:

- Increased productivity: The robot’s high speed and precision enable it to perform tasks quickly and accurately, leading to increased productivity.

- Improved efficiency: The 6 axis robot model is designed to perform tasks with minimal waste and maximum efficiency, reducing production costs.

- Enhanced flexibility: The robot’s flexibility and adaptability enable it to perform a wide range of tasks, making it an ideal solution for industries with varying production requirements.

- Reduced labor costs: The 6 axis robot model can perform tasks autonomously, reducing labor costs and improving workplace safety.

🤖 Note: The 6 axis robot model requires specialized training and maintenance to ensure optimal performance and longevity.

Implementation and Integration

Implementing and integrating the 6 axis robot model requires careful planning and consideration. Some key factors to consider include:

- Task analysis: Analyze the tasks to be performed by the robot to determine the required precision, speed, and flexibility.

- Workspace design: Design the workspace to accommodate the robot’s movements and ensure optimal performance.

- Safety protocols: Implement safety protocols to ensure workplace safety and prevent accidents.

- Maintenance and training: Provide regular maintenance and training to ensure optimal performance and longevity.

Conclusion

The 6 axis robot model is a powerful tool for boosting industrial efficiency. Its flexibility, precision, and high speed make it an ideal solution for industries with varying production requirements. By understanding the features, applications, and benefits of the 6 axis robot model, businesses can harness its potential to improve productivity, efficiency, and profitability.

What are the main advantages of the 6 axis robot model?

+

The main advantages of the 6 axis robot model include high precision and accuracy, flexibility and adaptability, high speed and repeatability, and compact design.

What industries can benefit from the 6 axis robot model?

+

The 6 axis robot model can benefit industries such as manufacturing, logistics, healthcare, and food processing.

How do I implement and integrate the 6 axis robot model?

+

Implementing and integrating the 6 axis robot model requires careful planning and consideration of factors such as task analysis, workspace design, safety protocols, and maintenance and training.